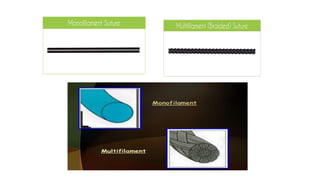

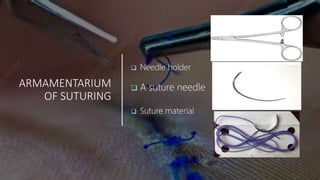

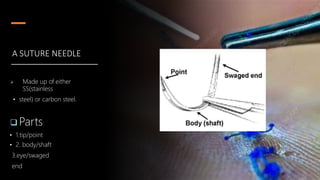

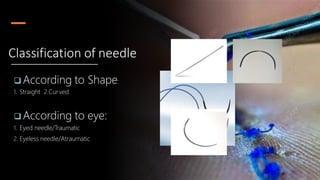

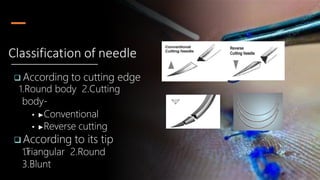

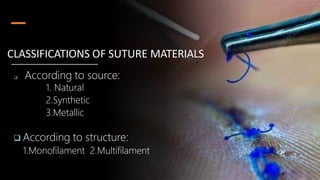

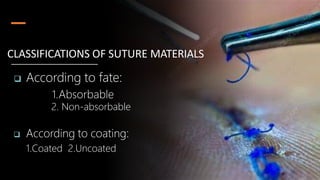

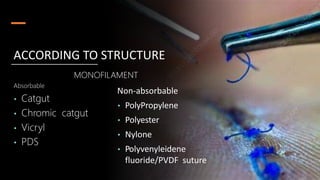

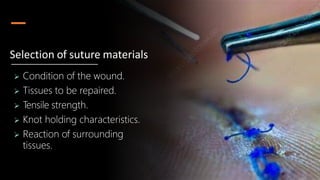

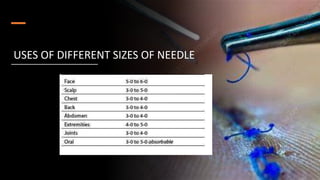

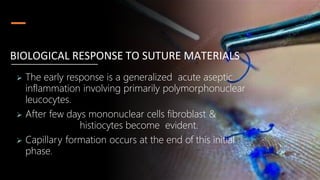

The document discusses sutures and suturing materials. It defines sutures as stitches used to approximate wound edges to help healing. Suture materials are synthetic fibers that hold wounds closed until natural scar tissue forms. The goals of suturing are wound edge apposition, tension, hemostasis, and infection prevention to produce a good scar. Suture characteristics include physical structure (monofilament or multifilament), tensile strength, absorbability, and biological behavior. Common suturing tools are needle holders, needles of varying shapes and tips, and materials like polypropylene, silk, and vicryl which are selected based on wound and tissue factors.