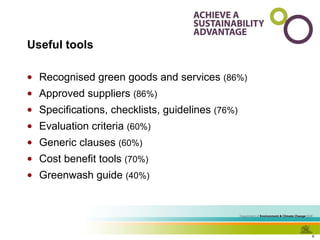

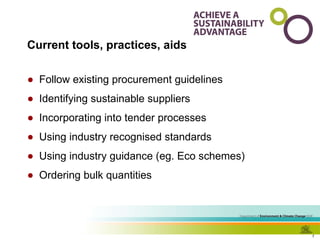

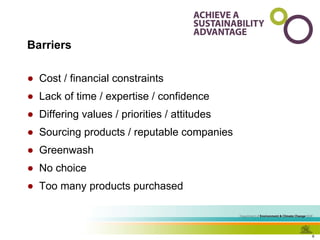

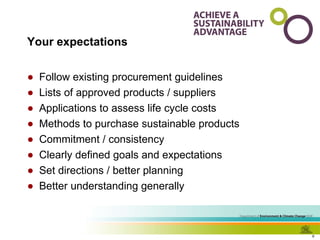

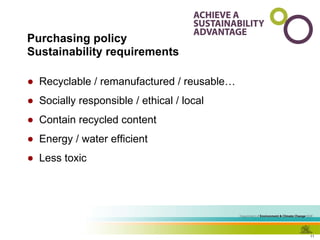

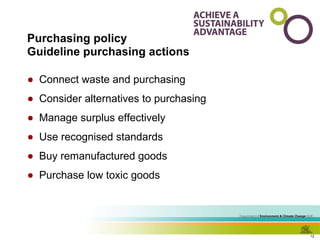

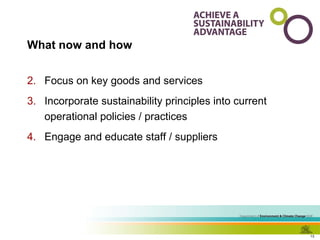

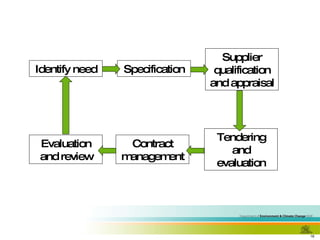

The document summarizes the results of a university supply chain workshop. It discusses the major purchases made by the university, the current use of sustainable criteria in procurement, useful tools and current practices, barriers to sustainability, expectations for improvement, guidelines for a purchasing policy, and next steps to focus on key goods and services and incorporate sustainability. Key areas to focus on include developing a hit list of common goods, standards and specifications, a preferred supplier list, identifying control points in the procurement process, and engaging stakeholders.