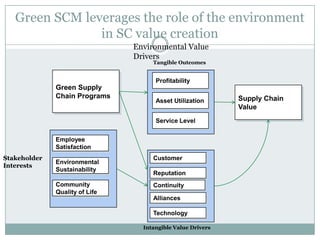

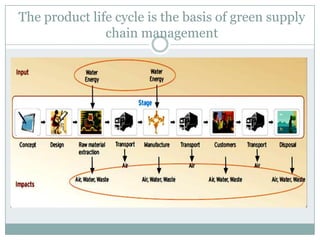

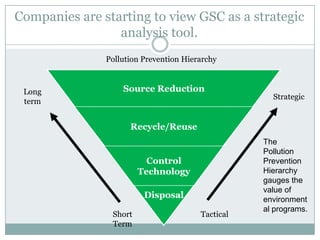

This document presents information on green supply chain management and the use of information technology in green SCM. It discusses how green SCM recognizes the disproportionate environmental impact of supply chain processes. It also describes how companies can leverage the environment in supply chain value creation. The document outlines how IT can be used to improve purchasing, operations, logistics, and customer relationships in green SCM. It emphasizes that green SCM efforts need to demonstrate clear business value to gain support.