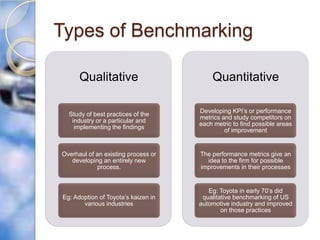

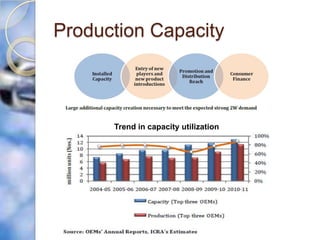

Benchmarking involves comparing business processes and performance metrics to best practices. This study benchmarks the supply chain of major Indian two-wheeler companies from 2009-2012. It analyzes total supply chain length, efficiency, and working capital productivity. Hero MotoCorp had the shortest supply chain length of 11 days and most efficient supply chain. TVS had the longest length of 28 days and least efficient supply chain. All companies showed negative working capital productivity due to capacity expansion investments. Recommendations include reducing distribution time for Bajaj, adopting JIT for TVS and Enfield to cut inventory costs, and improving production efficiency for TVS.