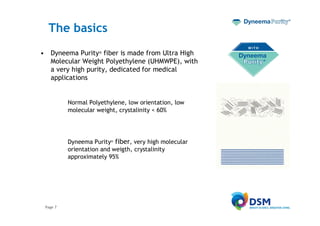

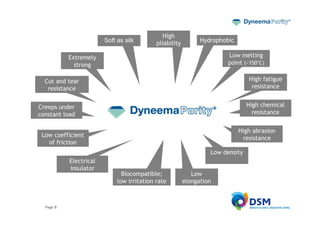

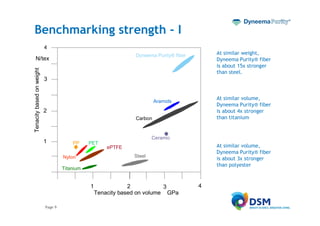

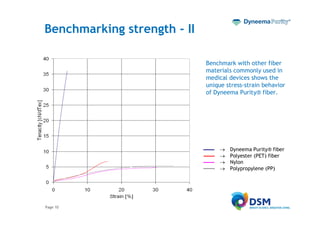

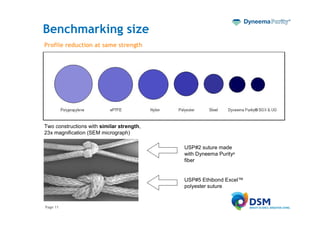

Dyneema Purity® fiber is a medical grade fiber made from ultra high molecular weight polyethylene. It is the strongest fiber available for medical use. The document discusses the properties of Dyneema Purity® fiber that make it suitable for applications such as sutures and ligament repair, including its high strength, flexibility, durability, and biocompatibility. Over 10 million patients have had medical devices implanted using Dyneema Purity® fiber due to its unique combination of properties.

![Chemical resistance

Chemical Conditions Tensile

strength

Conc. [%] Temp. Exp. time retention

[ºC] [hr]

Inorganic acids

HCl 10 20 5000 90-100 %

HNO3 10 20 5000

H2SO4 0.24 60 168

Ultra High Molecular Weight Polyethylene

Organic acids

CH3COOH 100 20 5000 90-100 %

95% crystalline

Bases No chemical groups

Ca(OH)2 0.25 60 168 90-100 %

Hydrophobic (Surface tension 27 mN/m)

NaOH 10 20 5000

Organic solvents

Very resistant against chemicals

Ethanol 100 20 5000 90-100 %

Acetone 100 20 5000

Trichloromethane 100 20 5000

Others

Distilled water 100 20 5000 90-100 %

Page 18](https://image.slidesharecdn.com/summarydyneemapurity2011-111116061455-phpapp01/85/Summary-dyneema-purity-2011-19-320.jpg)