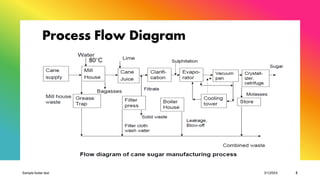

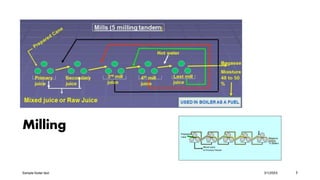

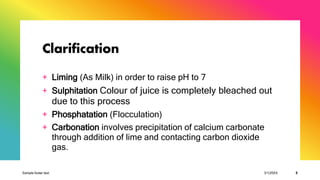

The sugar manufacturing process involves 7 key steps: 1) Cutting and shredding of sugarcane, 2) Milling to extract juice from cane, 3) Clarification to remove impurities from juice, 4) Filtration to further refine juice, 5) Evaporation to concentrate juice, 6) Crystallization to form sugar crystals, and 7) Centrifugation to separate raw sugar from molasses. The process aims to produce refined sugar while extracting byproducts like bagasse, molasses, and press mud.