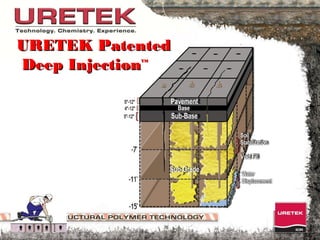

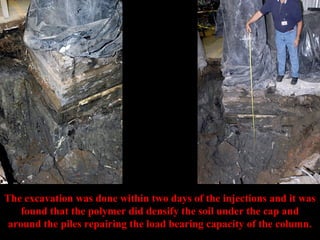

The document provides an overview of Uretek's services, which focus on high-density polyurethane grouting, deep injection processes, and soil stabilization solutions. It highlights specific case studies, including the rehabilitation of structures and addressing hydrostatic pressure issues, showcasing the advantages of their methods such as minimal disturbance and cost-effectiveness. Additionally, it details equipment used for micropile and soil nail installations suitable for restricted access situations.