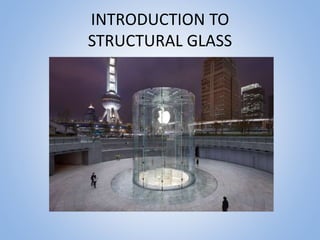

This document provides an introduction to structural glass, including:

- Structural glass is glass used in construction where it resists a portion of external loads rather than just a frame.

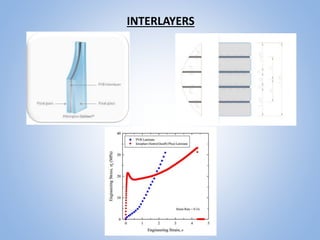

- Glass can be made stronger by heat treating it, laminating multiple layers, and connecting pieces together with interlayers and connectors.

- Modern structural glass designs include load bearing glass walls, fins, and other primary and secondary structures.

- Design codes provide allowable stress calculations and factors to consider for the effective thickness and strength of laminated and heat-treated structural glass.