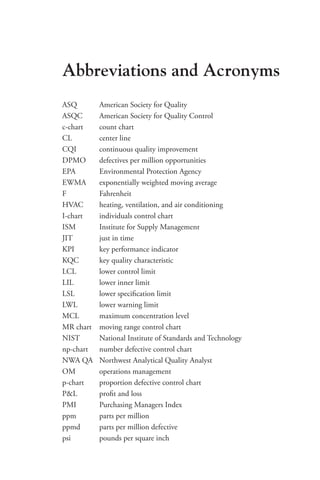

This book provides a conceptual understanding of statistical process control (SPC) for managers. It focuses on how and why managers should consider using SPC rather than technical calculations. The book utilizes popular software packages to create control charts and analyze data. It addresses why SPC is valuable, how to implement it, and how to use it to improve processes, products, and services. Examples from over 25 years of experience illustrate the concepts.

![Advanced Control Charts for Variables 65

are taken and where two different parts (A and B) are being produced by

the same process. The raw data are entered into the software that calculates

the delta statistic (Observation – Target). Delta-bar, which is the mean of

the delta statistics for each sample [for example (0.002 + 0.004)/2 = 0.003

Delta-bar for Sample No. 1)], is plotted on the delta chart.

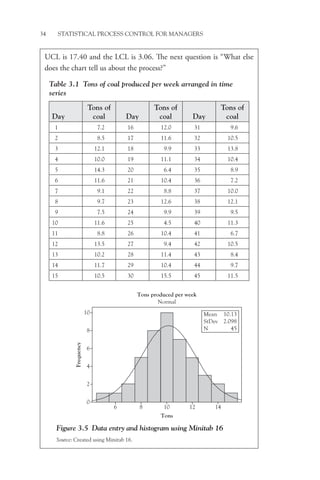

The delta chart, shown in Figure 5.3 with its companion R-chart,

looks like the x-bar chart, but note that if all parts are, on average, exactly

centered on the target value, the central line (CL) of the delta chart will

be zero with the points evenly distributed on either side of the CL when

the process is operating in control.

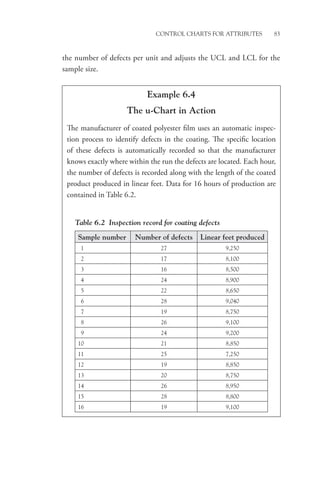

Table 5.1 Calculation of the delta statistic

Sample

No.

Part

ID Target

Obser-

vation

1 raw

Obser-

vation

1 delta

Obser-

vation

2 raw

Obser-

vation

2 delta

Delta-

Bar

1 A 1.000 1.002 0.002 1.004 0.004 0.003

2 A 1.000 0.991 –0.009 1.009 0.009 0.000

3 B 1.500 1.497 –0.003 1.501 0.001 –0.001

4 B 1.500 1.501 0.001 1.503 0.003 0.002

Delta-R chart of C1, ..., C2

Sample

Sample

mean

Sample

range

UCL = 0.01588

X = 0.001

LCL = −0.01388

−0.01

0.00

0.000

0.006

0.012

0.018

0.024

0.01

0.02

1 2 3 4

UCL = 0.02586

R = 0.00791

LCL = 0

Sample

1 2 3 4

Figure 5.3 Delta and R-charts

Source: Created using Minitab 16.](https://image.slidesharecdn.com/statisticalprocesscontrol-231017131602-5a4010de/85/Statistical-Process-Control-pdf-88-320.jpg)