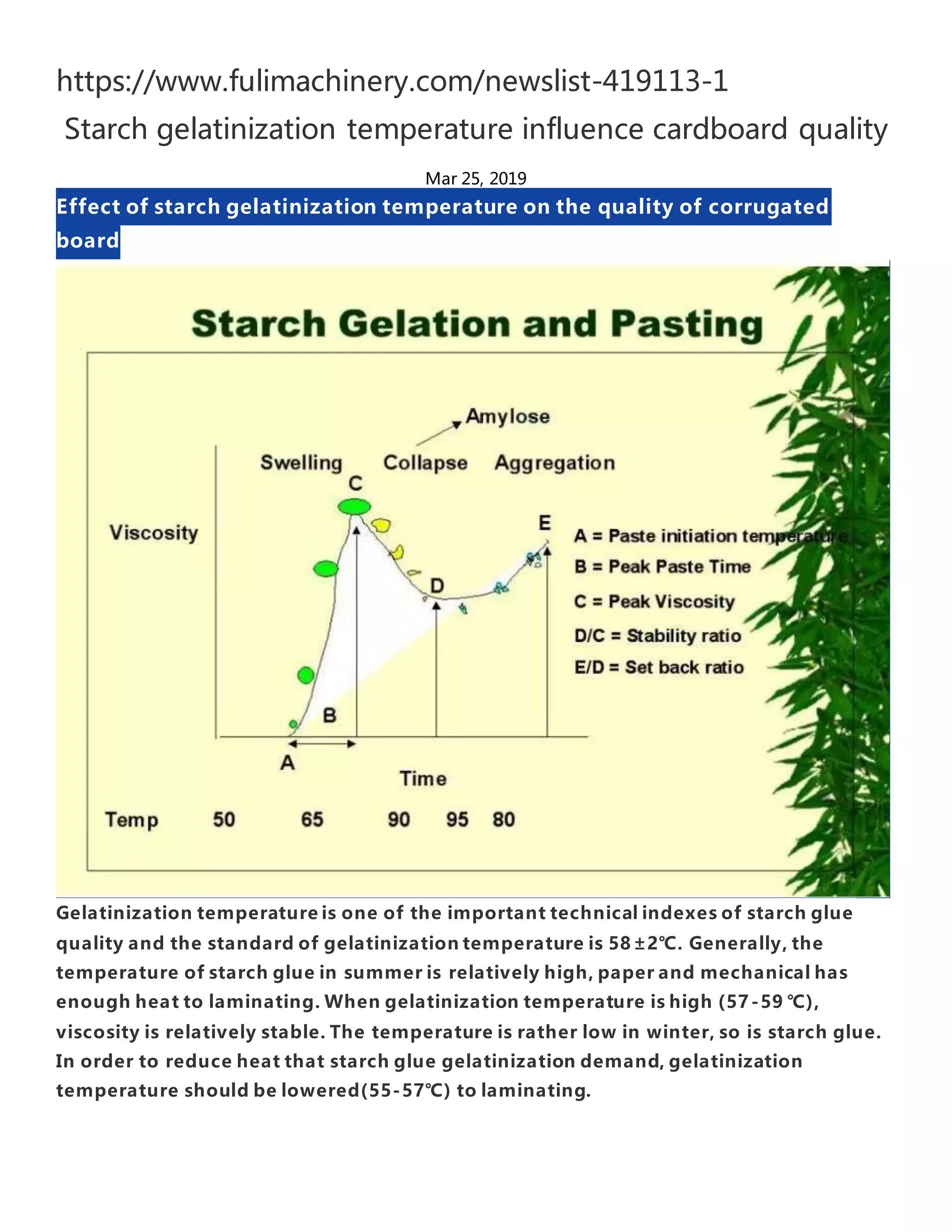

Gelatinization temperature is an important indicator of starch glue quality that directly affects the bonding of corrugated board. The gelatinization temperature should be between 55-59°C. Factors like the amount of sodium hydroxide gelatinizer, type and quality of starch, temperature during production, and production process can impact the gelatinization temperature. Maintaining a stable gelatinization temperature ensures proper bonding and high quality corrugated board.