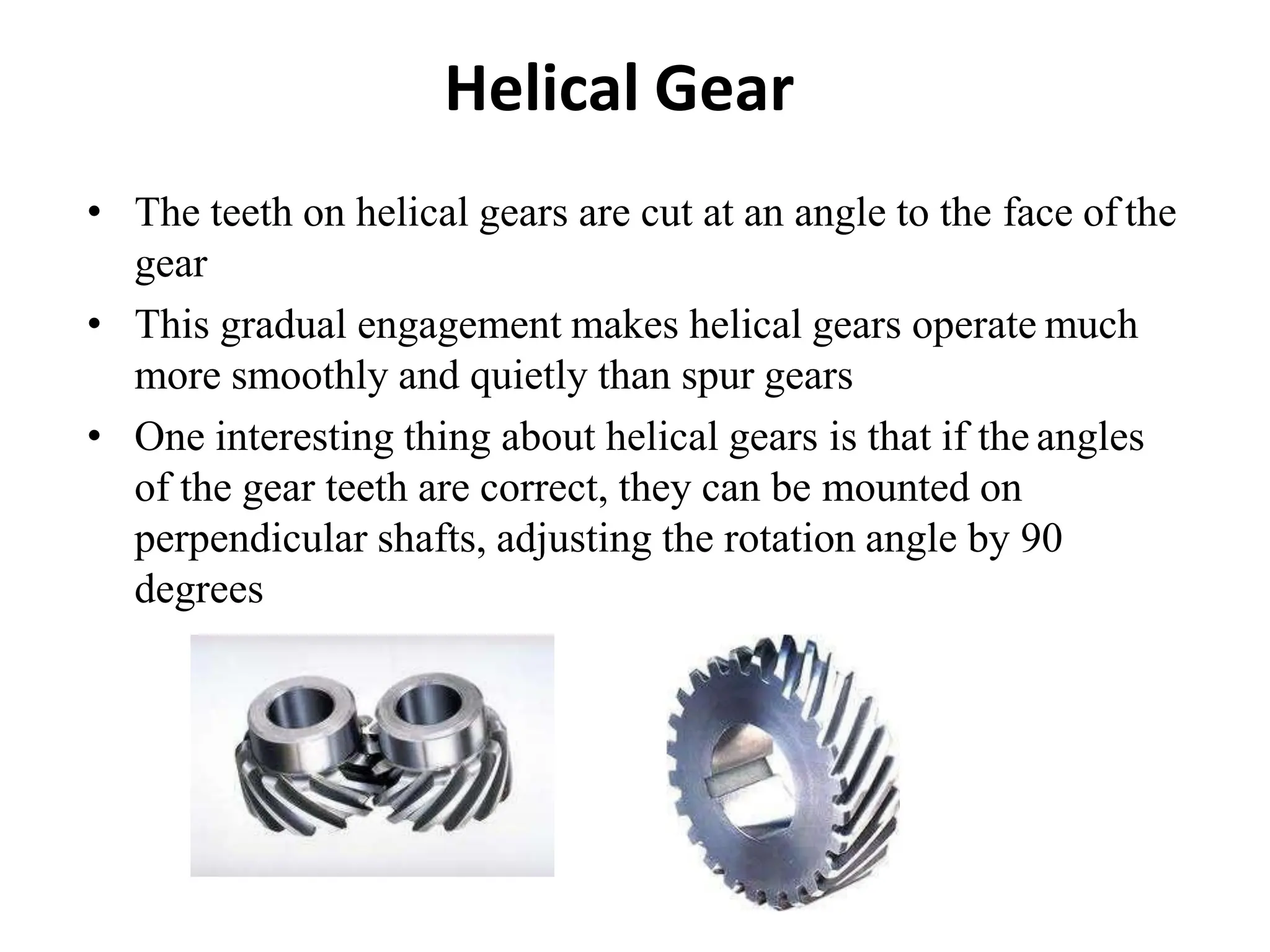

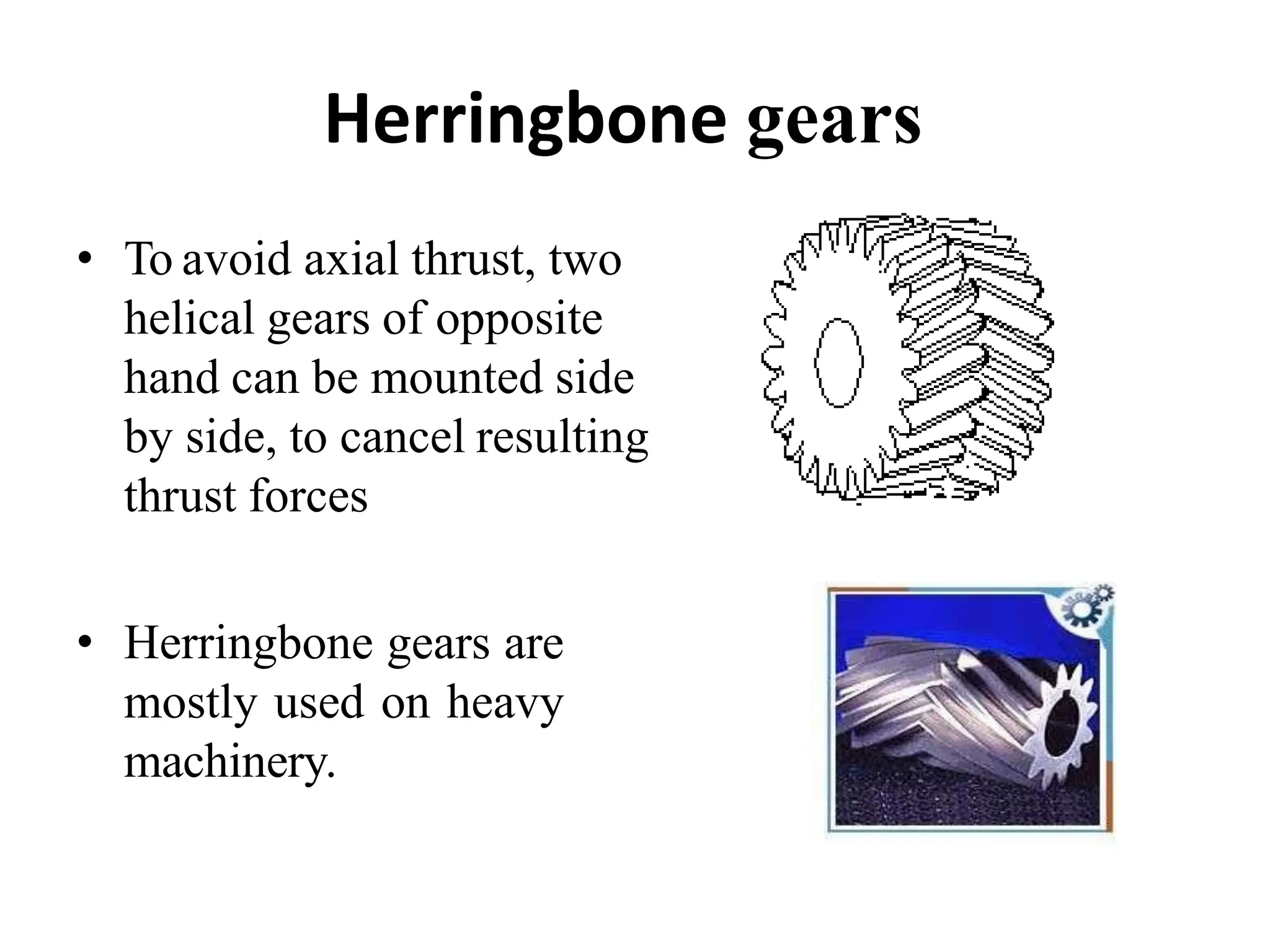

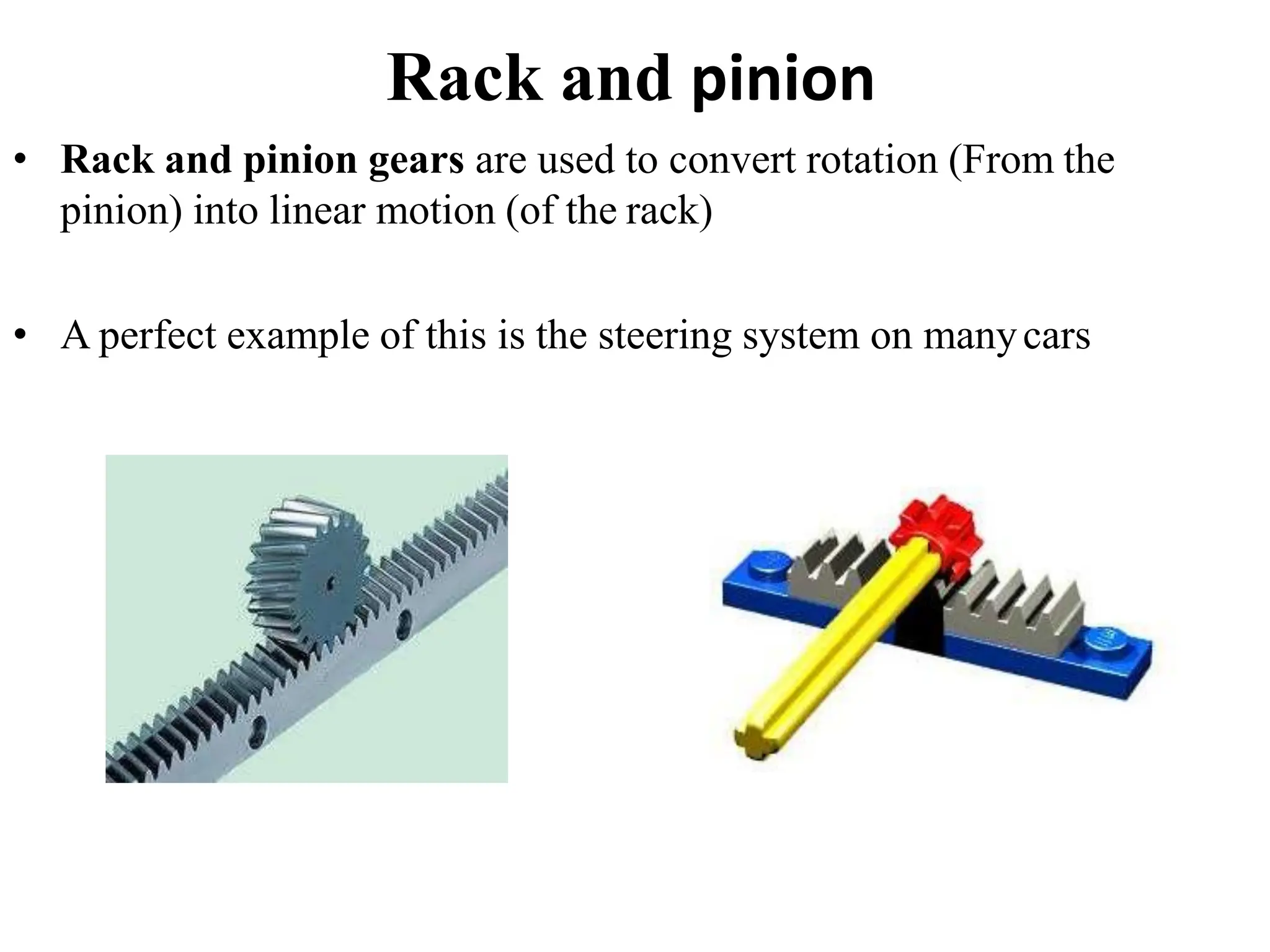

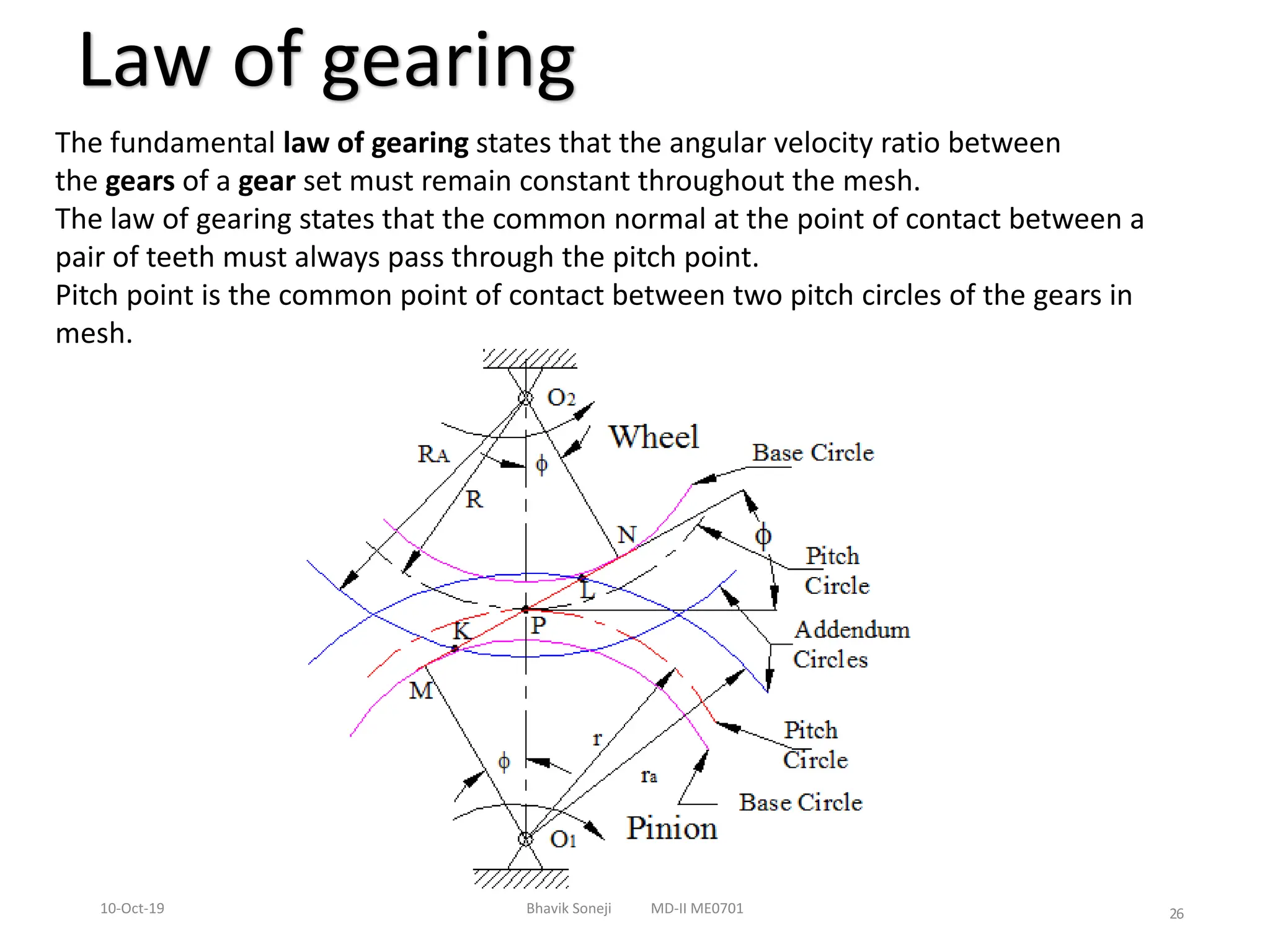

The document provides an overview of gears, focusing on types such as spur, helical, bevel, and worm gears, along with their applications and terminologies. It covers gear classification, materials, manufacturing processes, and fundamental gear design principles, including the law of gearing. Additionally, it includes numerical problems for the design of spur and helical gears based on power transmission requirements and material strength considerations.