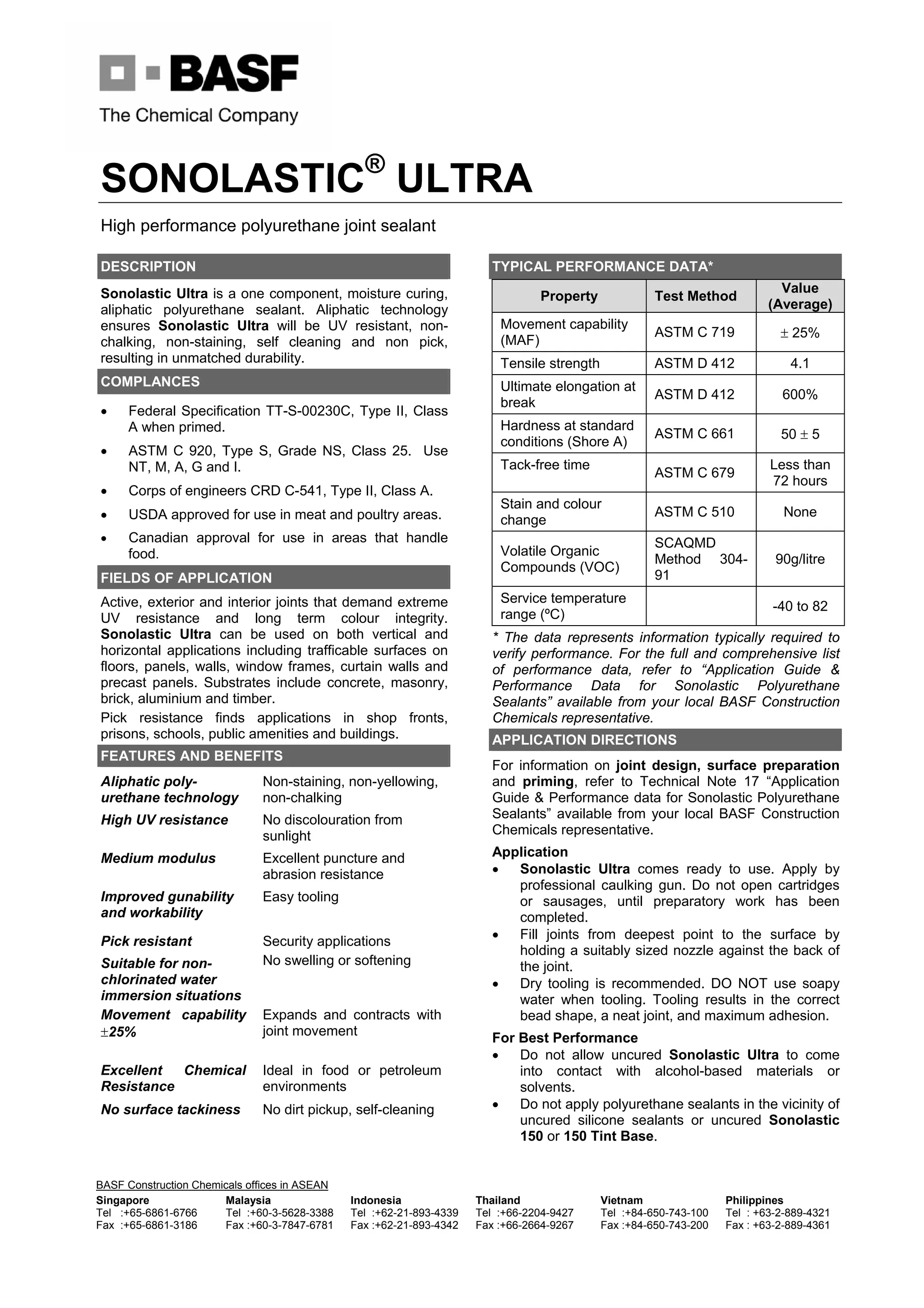

This document provides information on Sonolastic Ultra, a one-component, moisture-curing polyurethane joint sealant produced by BASF Construction Chemicals. It can be used for interior and exterior joints and demands extreme UV resistance. It is non-staining, flexible and pick resistant. Information is provided on product specifications, applications, installation instructions, packaging details, and safety precautions.