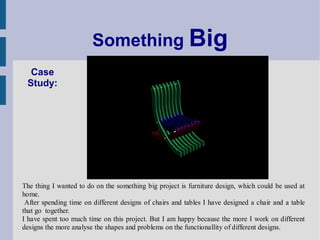

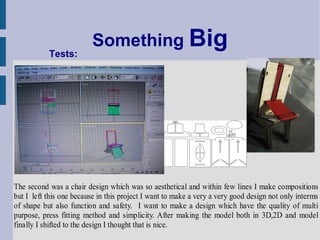

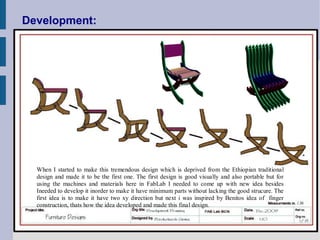

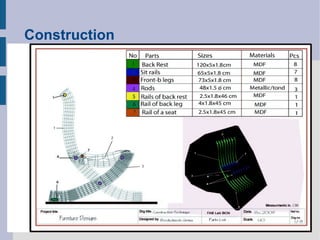

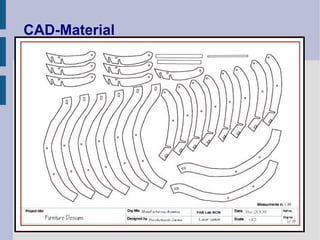

This document summarizes the development of a furniture design project. The designer created a chair and table that went together. Through multiple iterations and testing different designs, the designer settled on a design for a multi-purpose table that could be extended, as well as a chair designed for aesthetics, function, safety, and simplicity. The final chair design was inspired by traditional Ethiopian designs and incorporated a finger joint construction and press-fit assembly method. Though a full-scale model could not be produced due to machine limitations, the small-scale prototype demonstrated good structure, balance and strength.