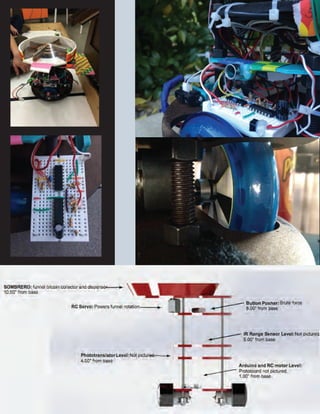

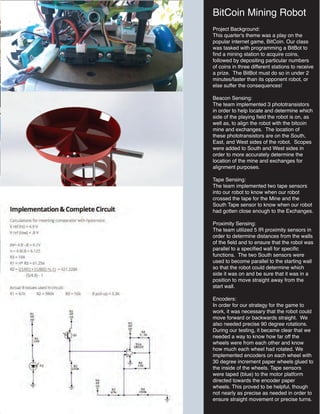

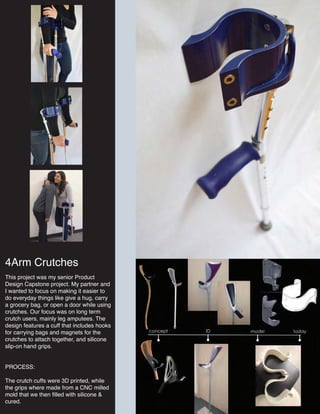

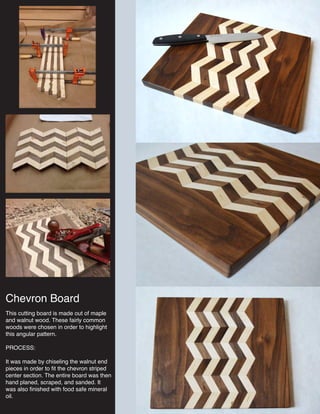

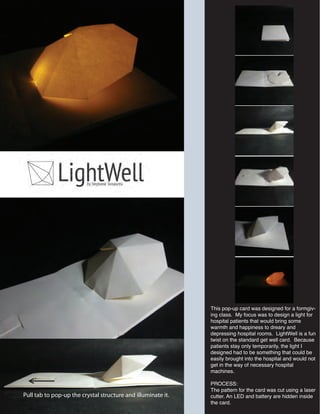

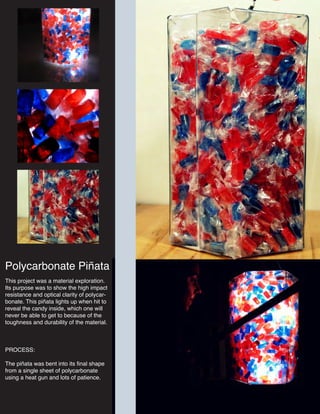

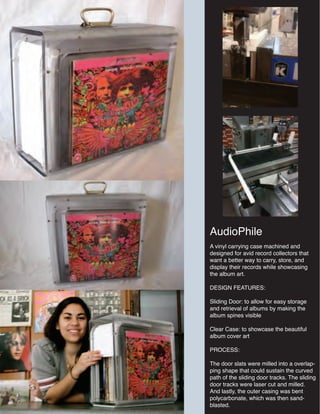

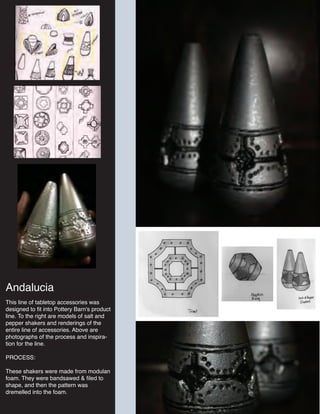

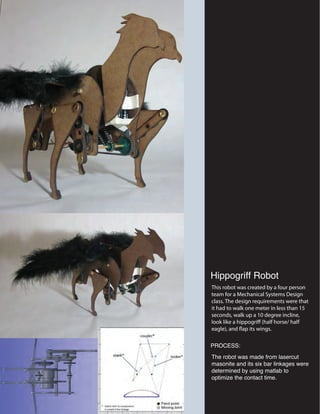

This document summarizes Stephanie Tomasetta's 2014 design portfolio. It includes projects focused on designing for autonomous vehicles, 3D printed ski pole baskets, an injection molded bitcoin mining robot, ergonomic 4-arm crutches, a portable slit lamp for developing countries, a chevron cutting board, a pop-up hospital room light card, a polycarbonate pinata, a vinyl record carrying case, Spanish-inspired table accessories, and a walking hippogriff robot. The projects utilized various design and prototyping processes like 3D printing, CNC machining, laser cutting, molding, and linkage optimization.