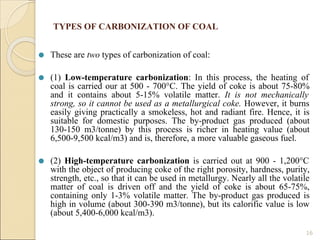

This document discusses solid fuels, with a focus on coal and coke. It defines primary and secondary fuels, and how they are classified based on physical state as solid, liquid, or gas. Coal forms from decayed vegetation over millions of years and is composed mainly of carbon. Coke is produced from coal through carbonization and is preferred for metallurgical processes due to its strength, porosity, and removal of undesirable sulfur. The document covers proximate and ultimate analysis methods to determine the composition of coal and evaluates quality based on factors like moisture, volatile matter, ash, carbon, hydrogen, nitrogen, and sulfur content. High-temperature carbonization is used to produce strong, porous metallurgical coke while retaining purity.