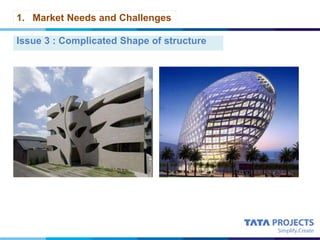

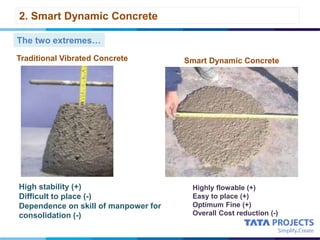

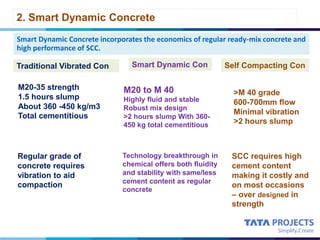

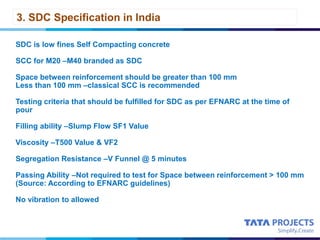

Tata Projects Limited introduces Smart Dynamic Concrete (SDC), an innovative concrete solution that eliminates the need for vibration during placement, allowing it to flow and compact under its own weight, thus facilitating faster construction. SDC offers improved homogeneity and strength with reduced water-cement ratios while addressing market challenges such as construction speed and managing skilled labor. The document outlines the specifications, benefits, and value propositions of SDC in the context of contemporary concrete technology and construction requirements.