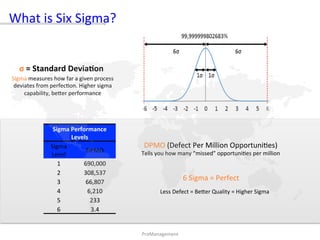

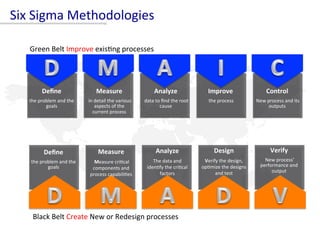

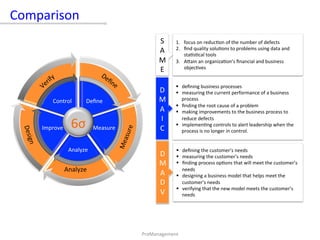

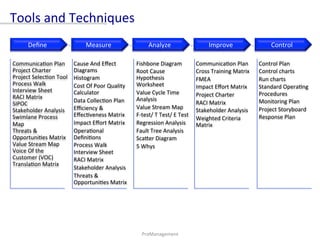

The document provides an overview of Six Sigma, a data-driven methodology aimed at improving process quality by reducing defects and enhancing performance. It outlines the Sigma levels and certifications, emphasizing the importance of statistical tools in achieving near perfection in processes. Additionally, it details the core methodologies, techniques, and tools used within Six Sigma to enhance productivity, reduce costs, and increase competitive advantage.