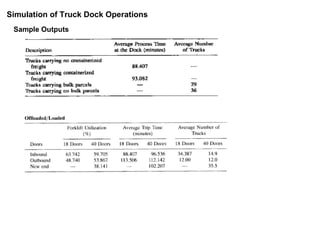

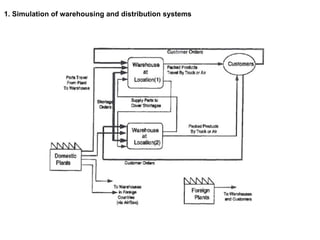

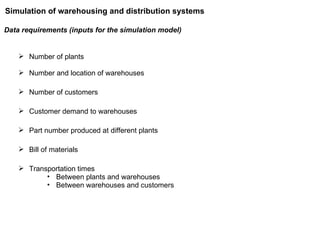

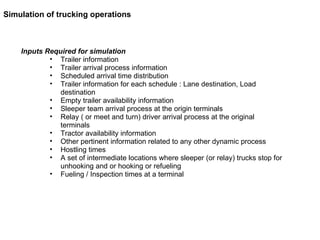

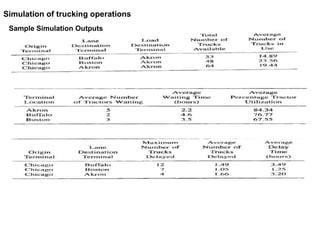

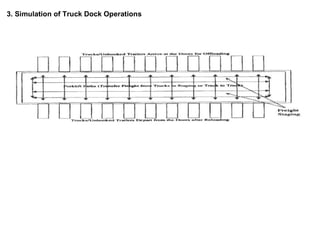

The document outlines the applications of simulation in logistics and transportation systems, emphasizing the categorization of simulation models for strategic, tactical, and operational planning. It discusses key elements involved in logistics such as direct and indirect resources, the roles of simulation in various operations like warehousing, trucking, and dock management, and highlights specific case studies. Additionally, it details inputs and outputs necessary for effective simulation modeling to optimize resource utilization and efficiency in transportation processes.

![Inputs Data for Truck-dock Simulation Two types of data inputs are required. The first types involves freight types, door information, resources used and equipment specifications as follows: Door information ( number of doors, door size ,door locations) Freight types (containerized, bulk [sorted/unsorted], loose freight) Resources (doors, forklifts, sorting conveyors) Operators Queue locations Forklift specifications (number and types, length and width, loaded/unloaded speed, park locations, work assignment, turning rules, pickup and deposit rules) Conveyor specifications (conveyor types, number of segments, input station characteristics, output station characteristics, segment speed, conveyor selection rules, freight movements) Simulation of Truck Dock Operations](https://image.slidesharecdn.com/simulationapplicationsinlogisticsandtransportation-13164450694402-phpapp01-110919101253-phpapp01/85/Simulation-Applications-In-Logistics-And-Transportation-44-320.jpg)