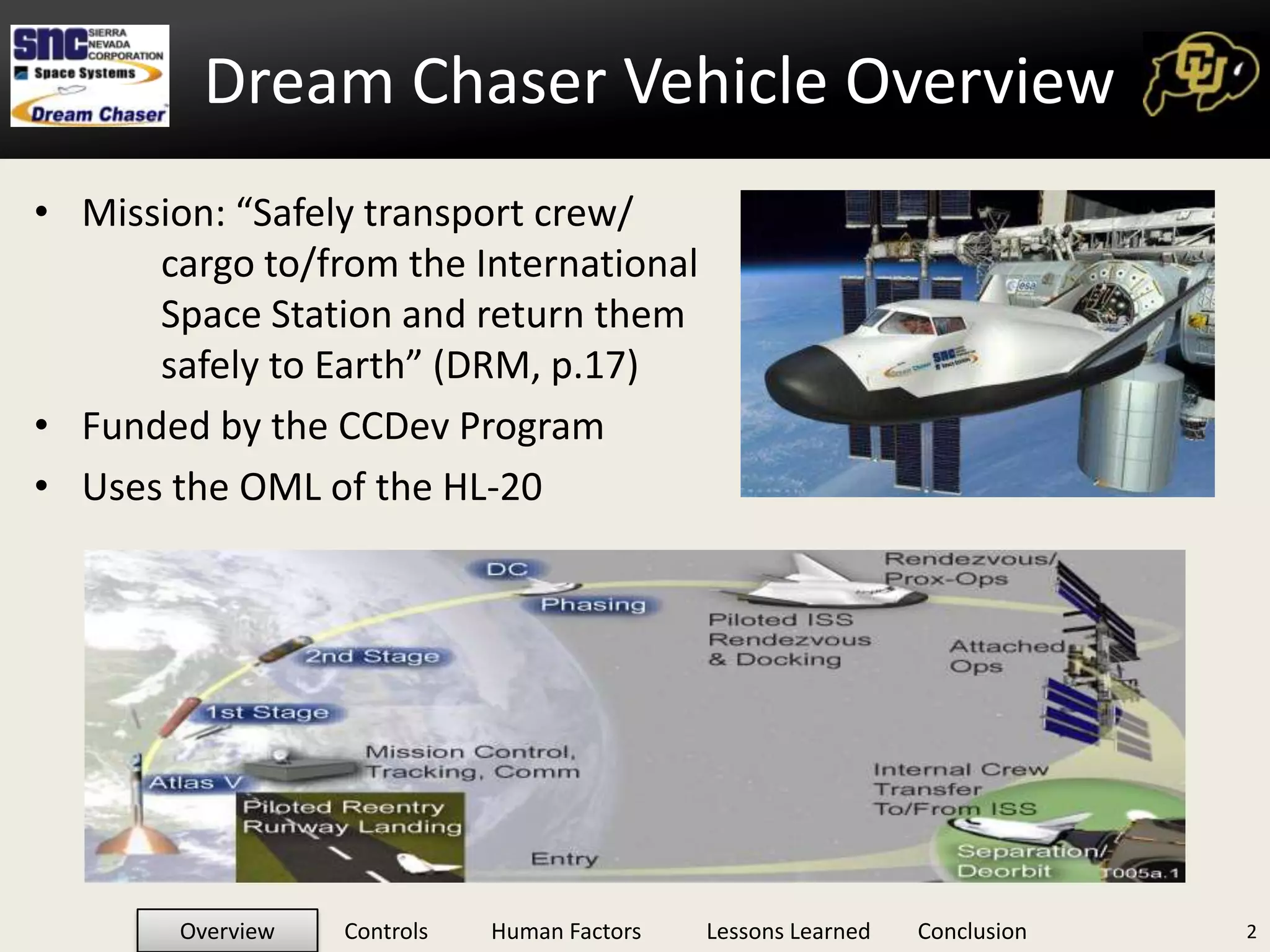

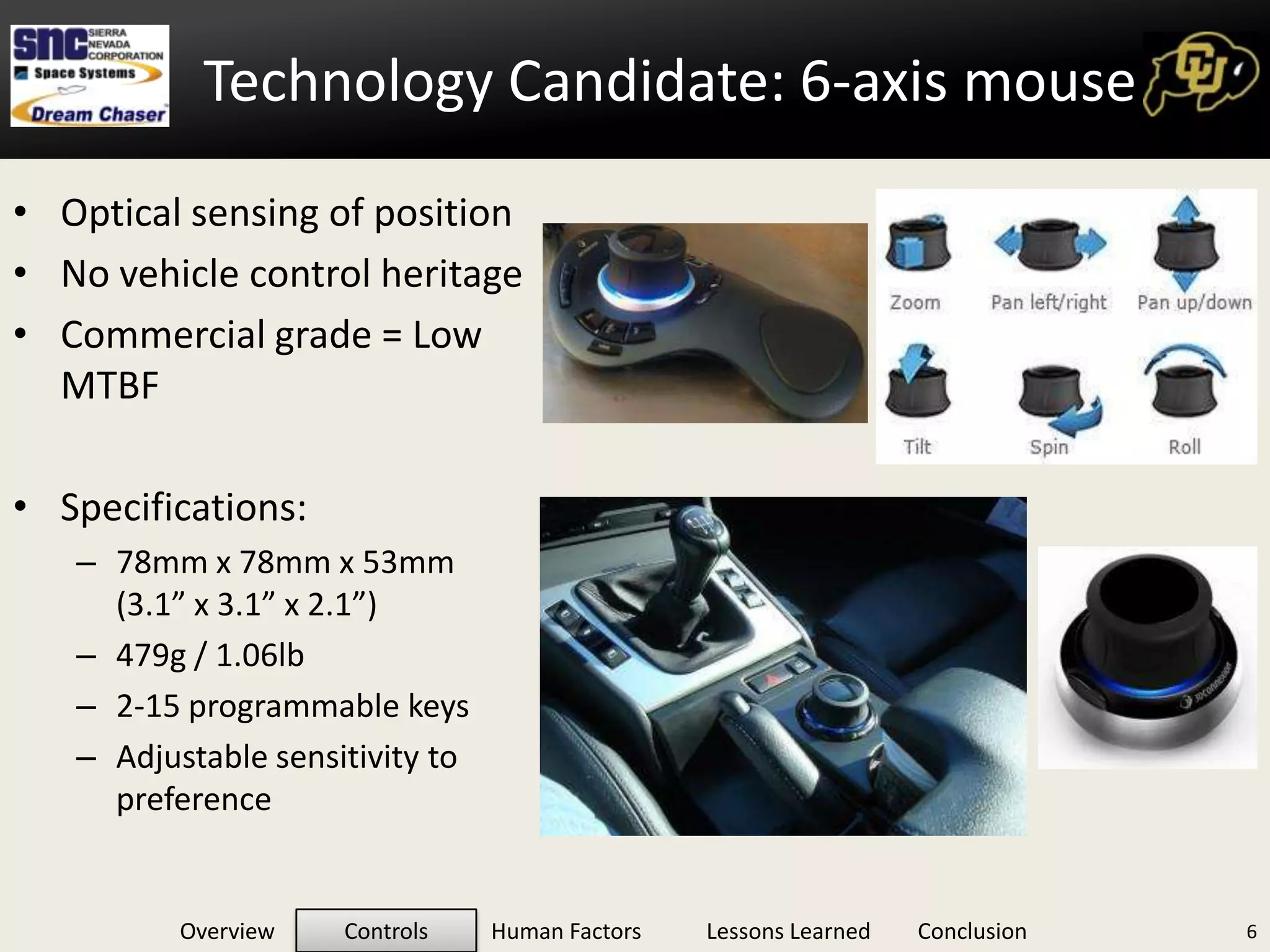

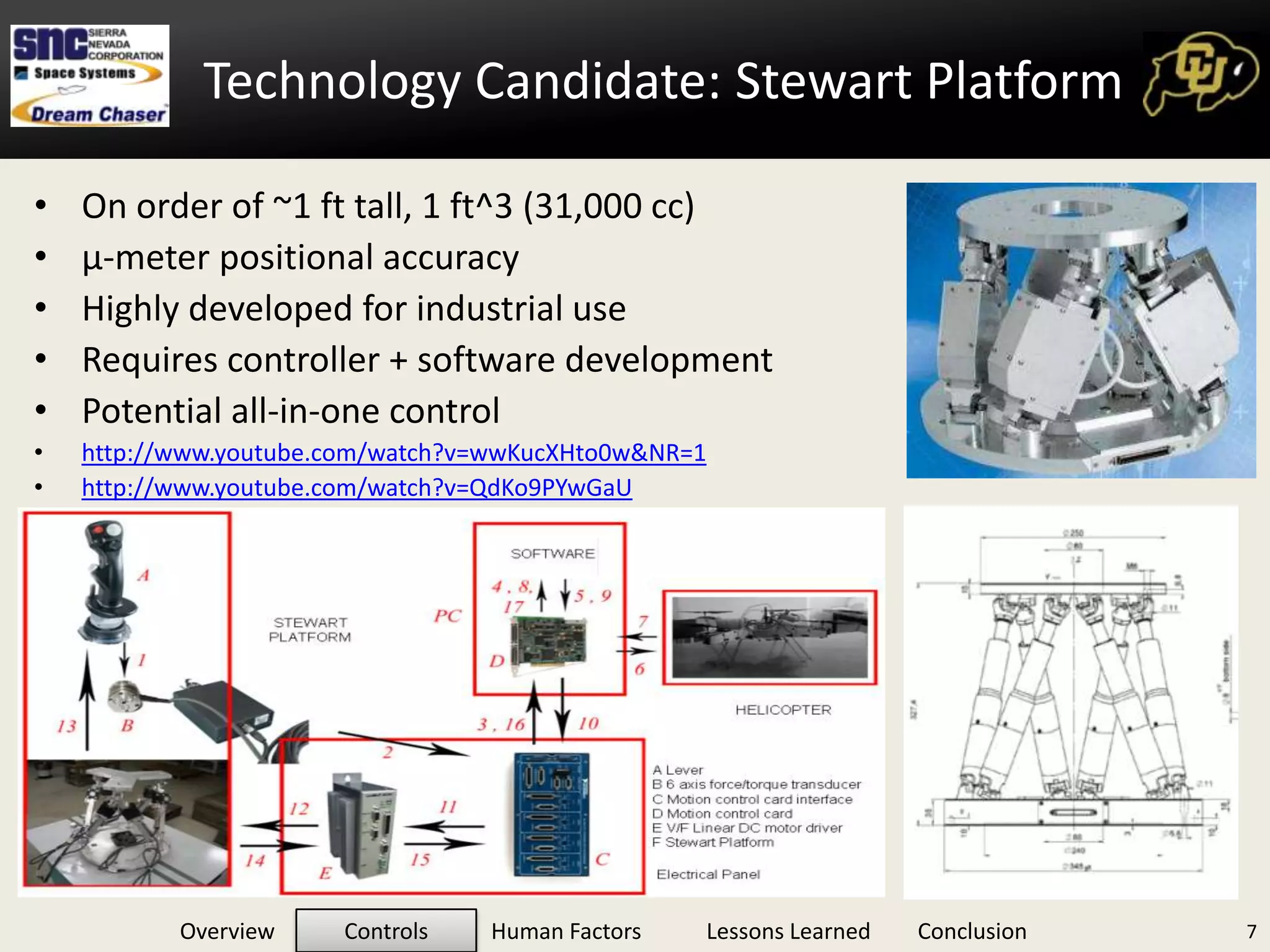

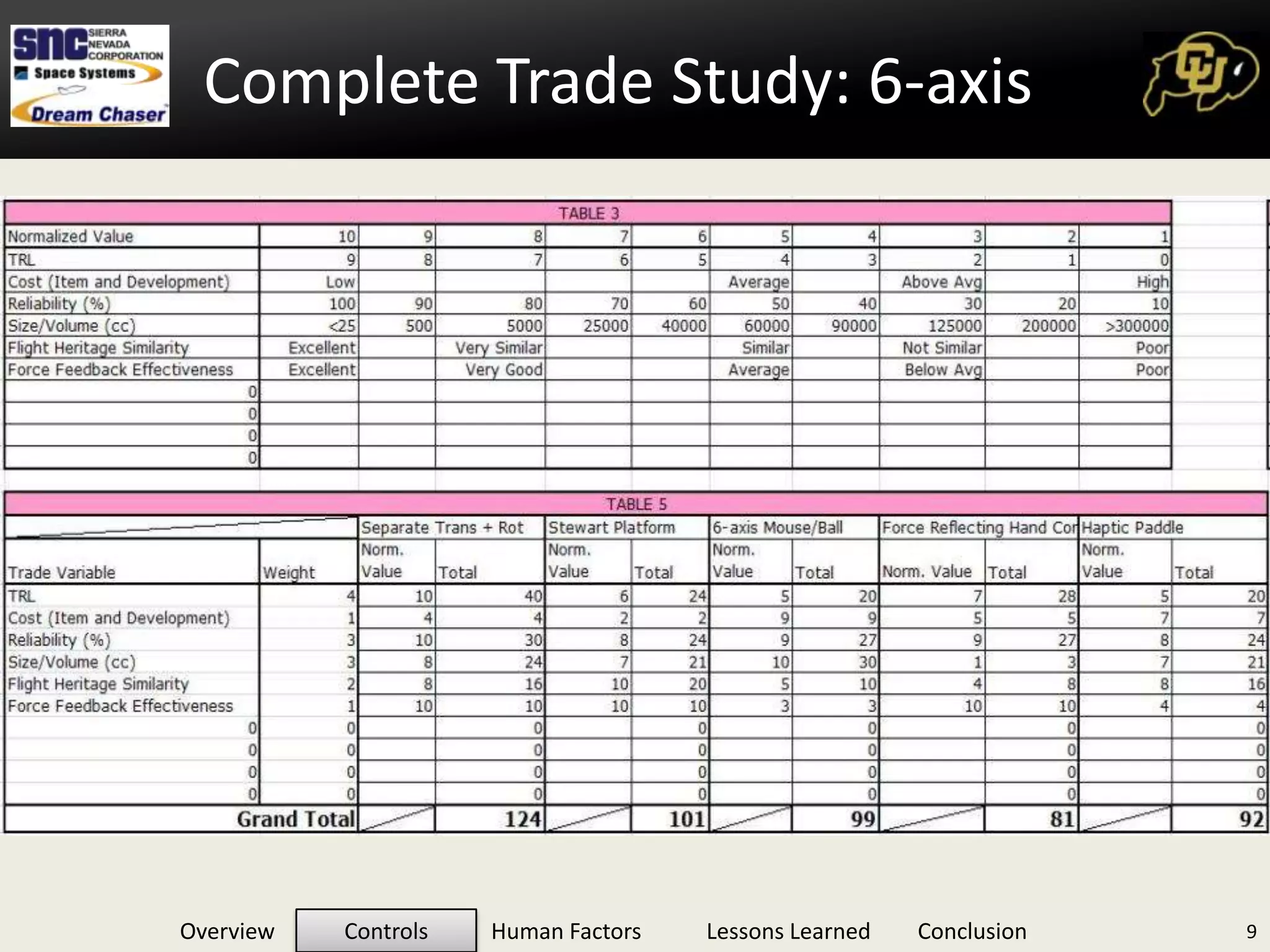

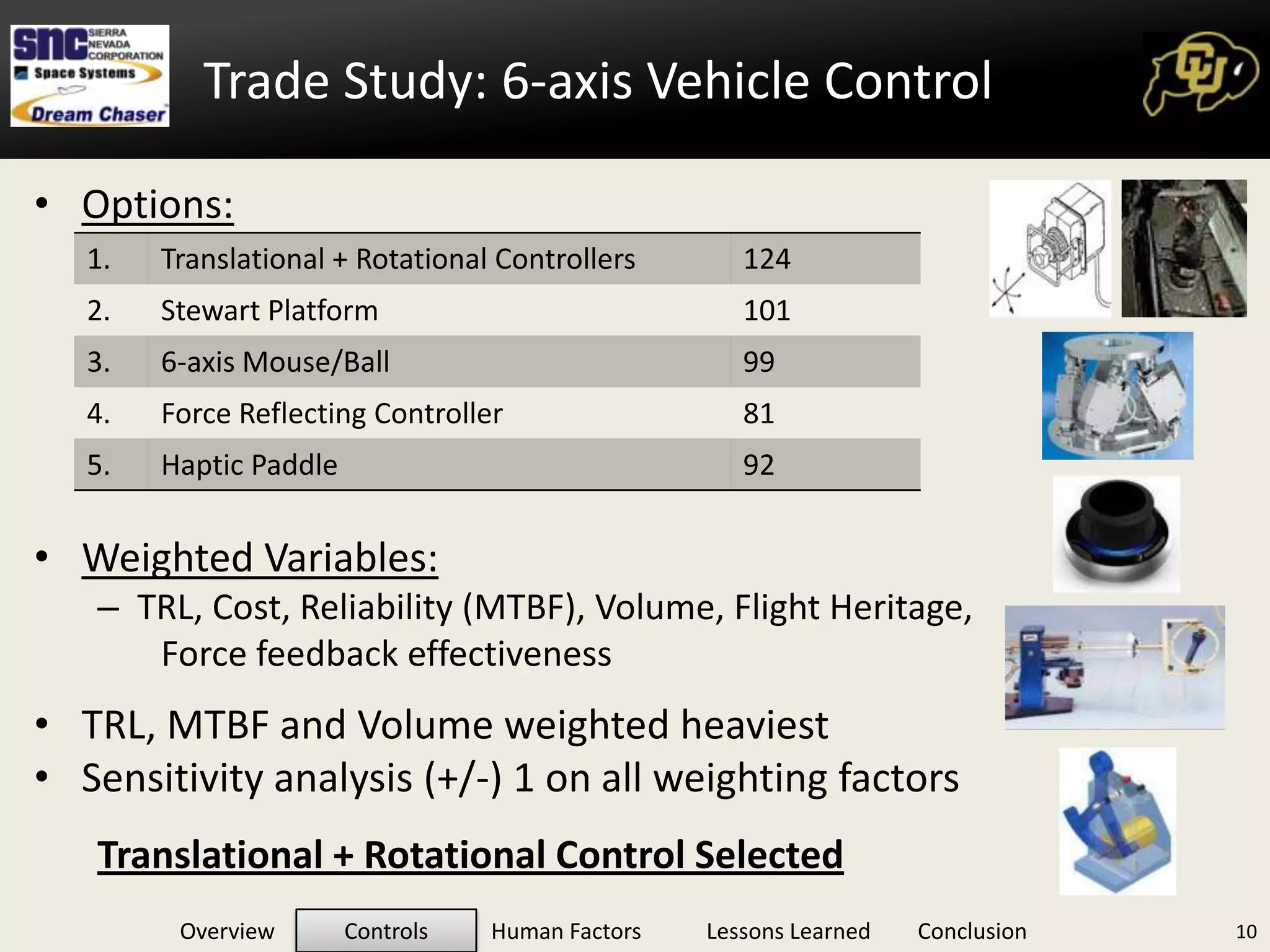

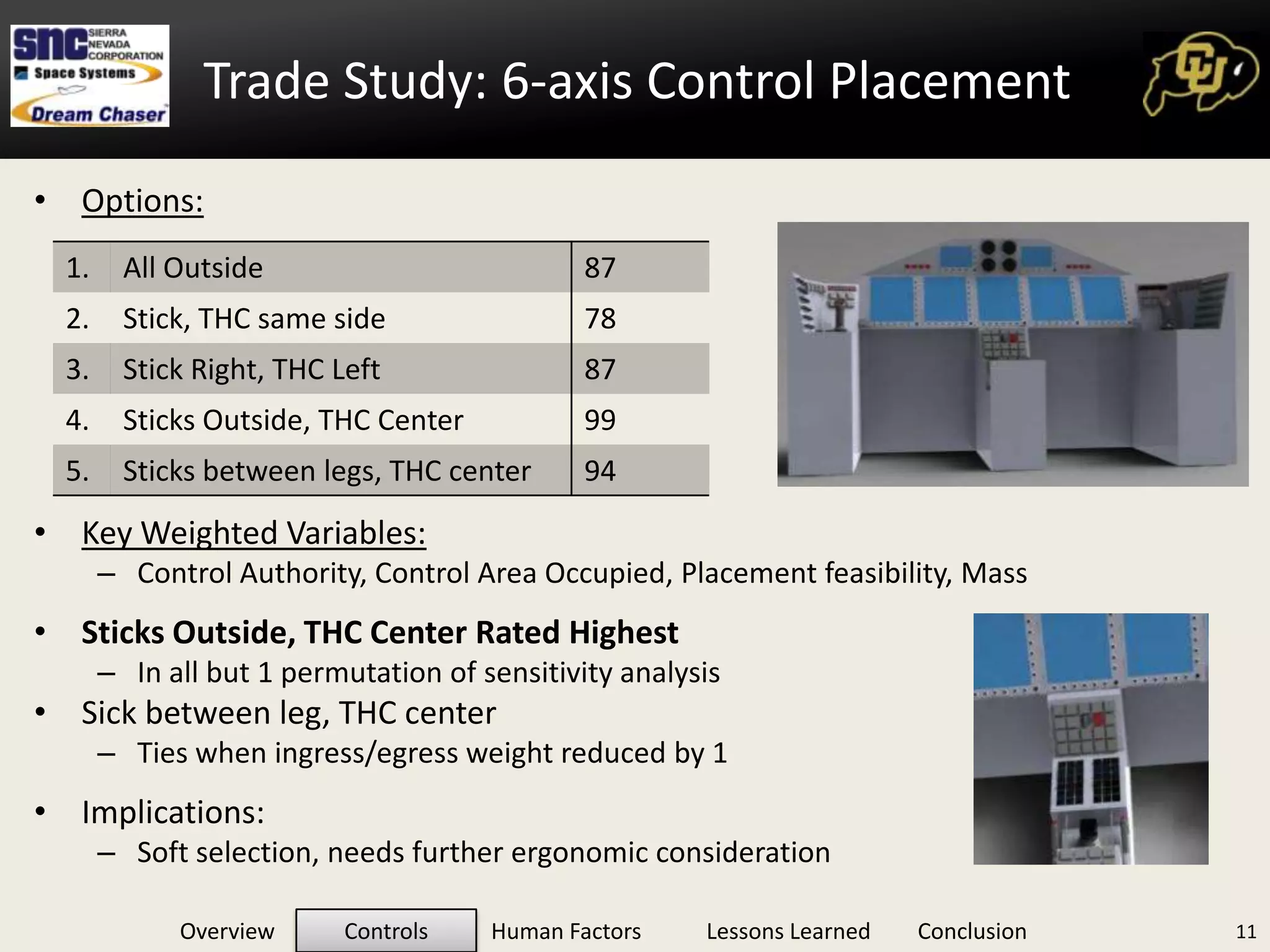

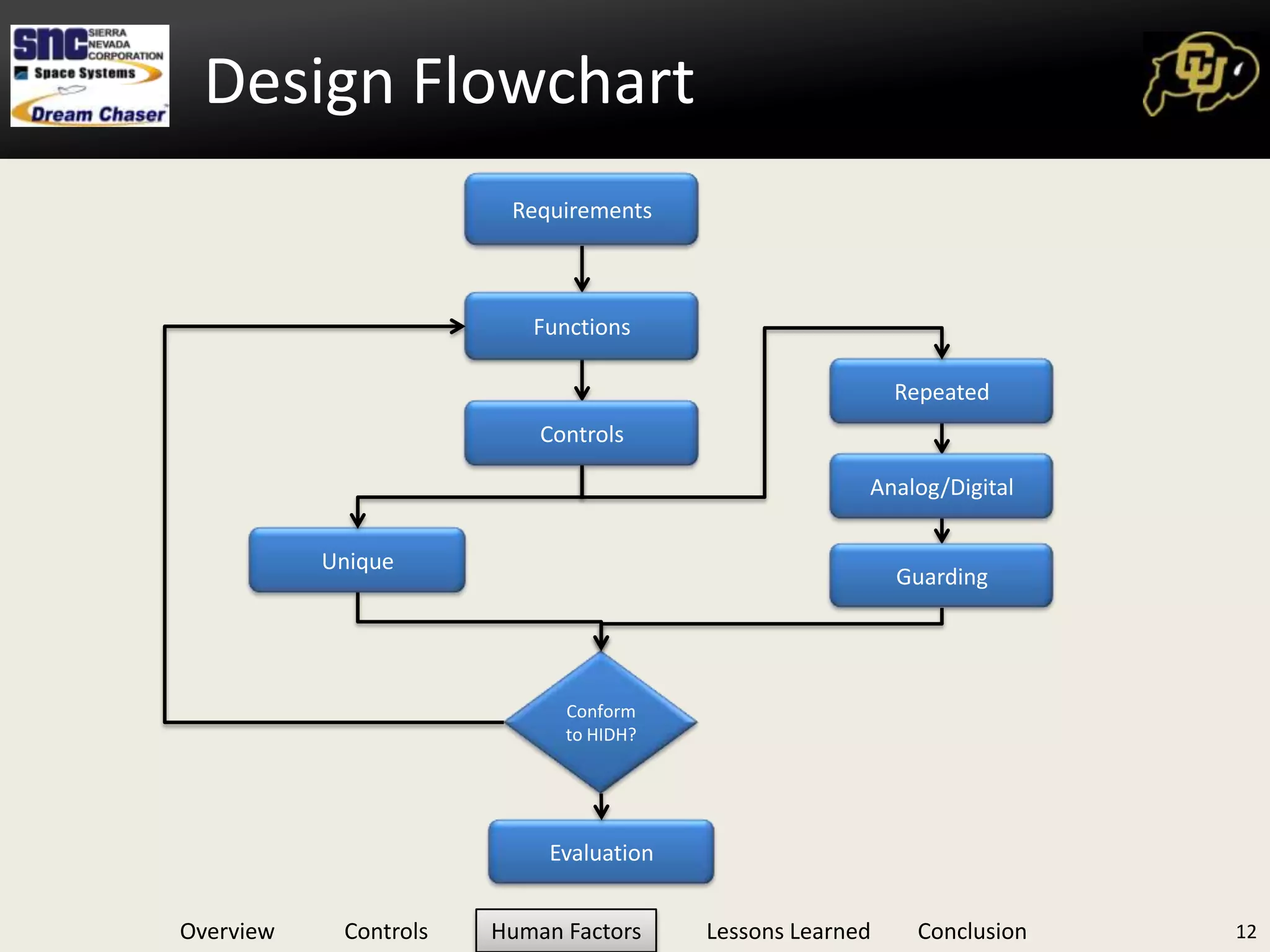

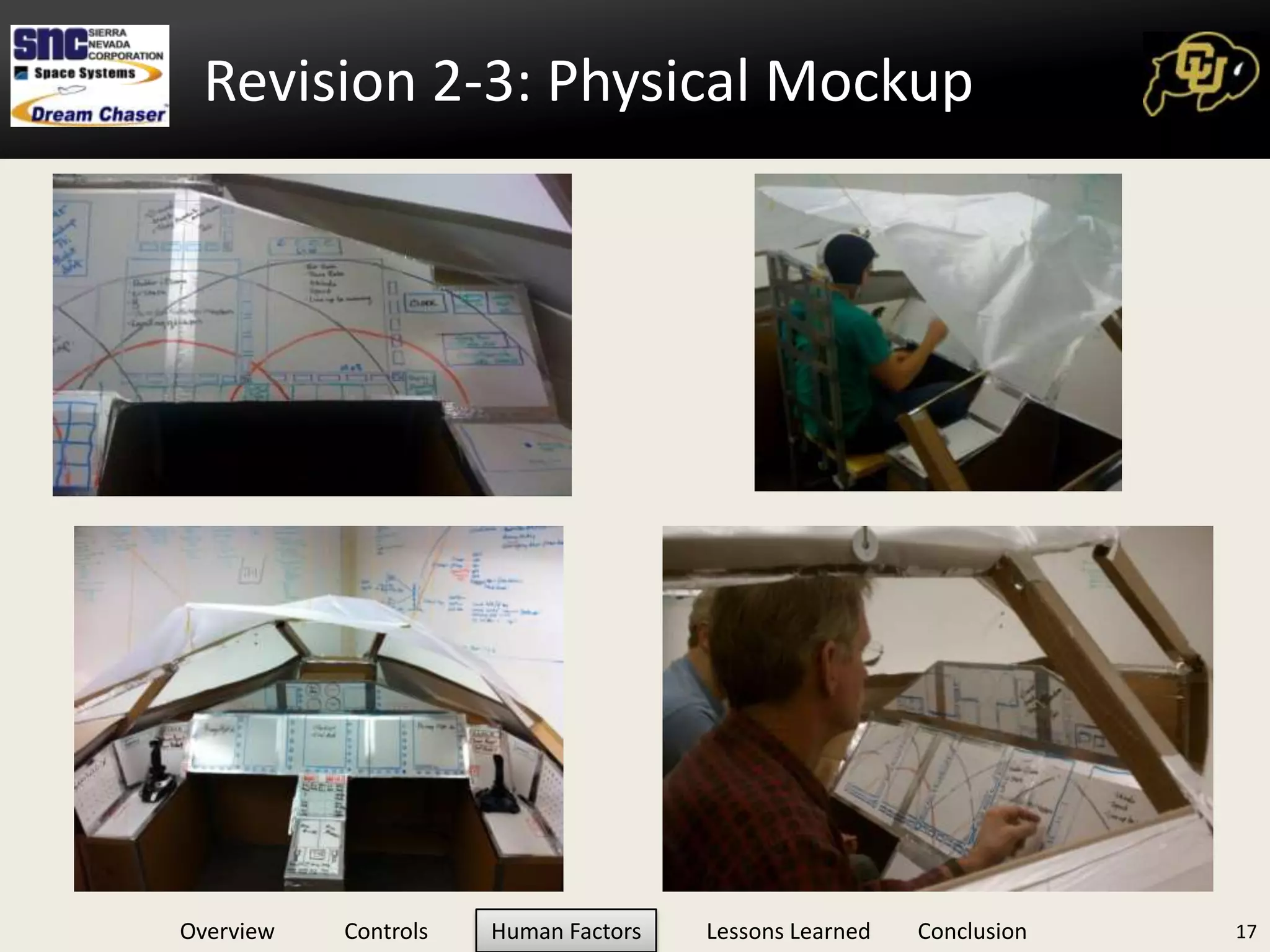

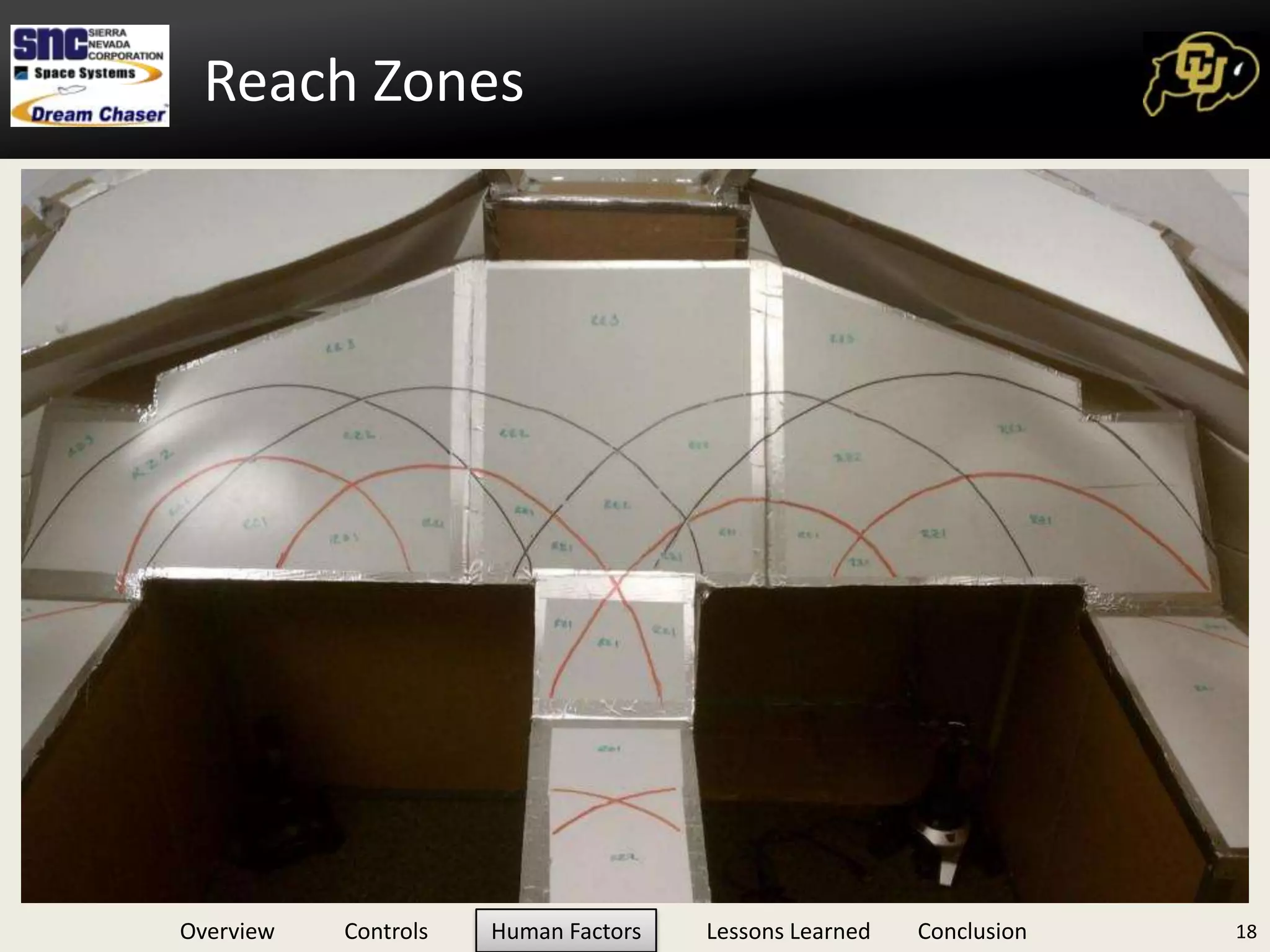

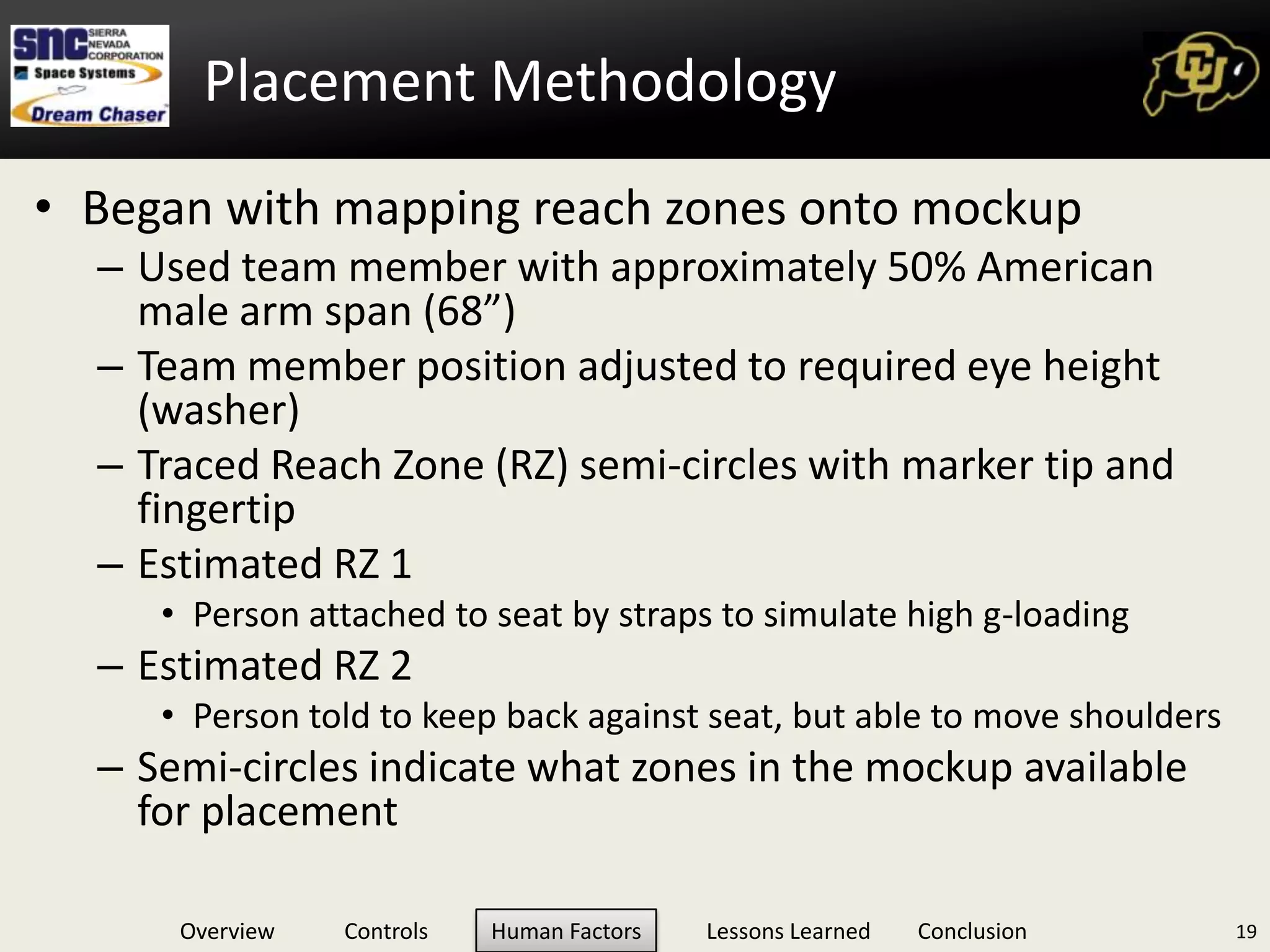

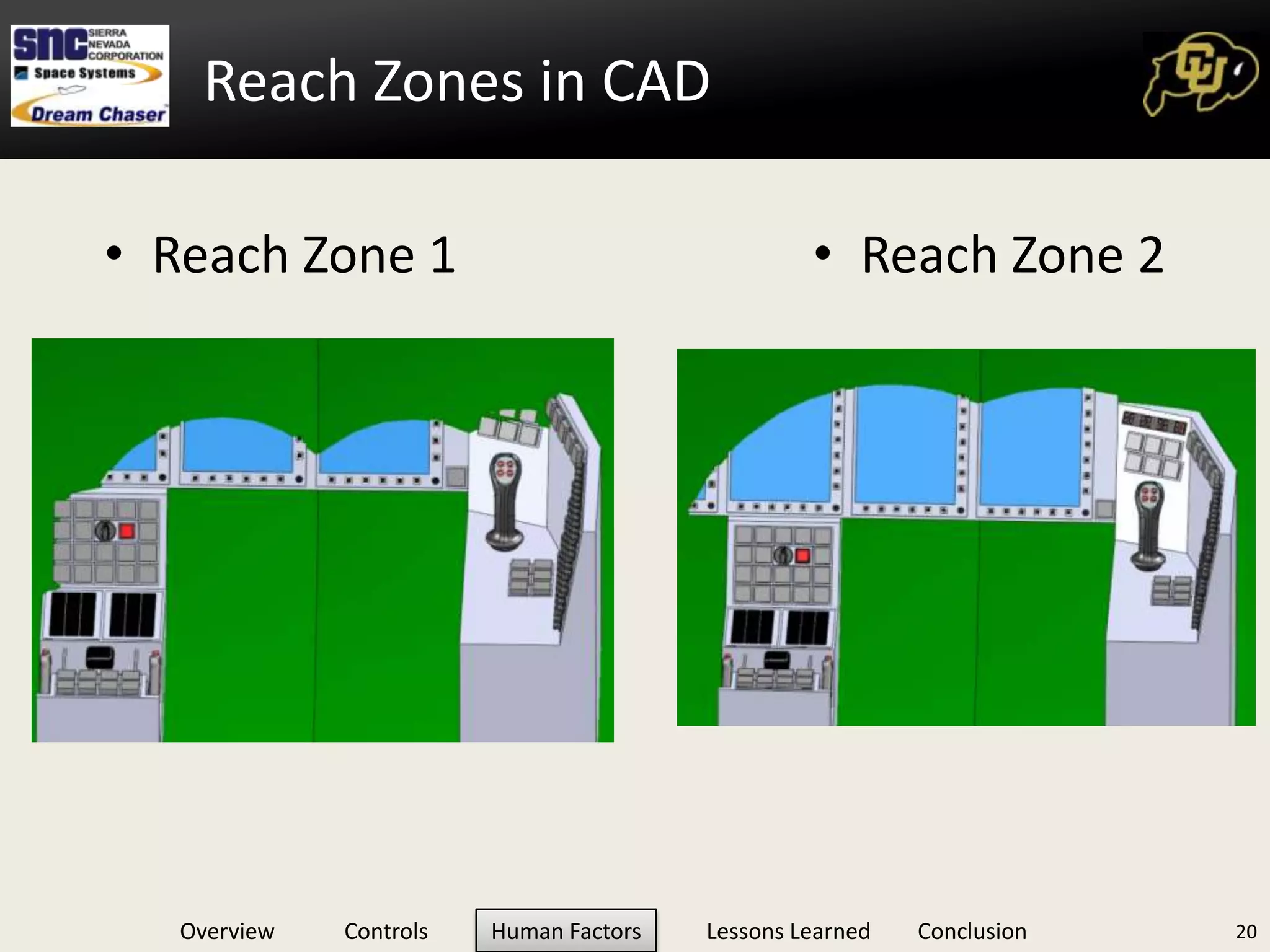

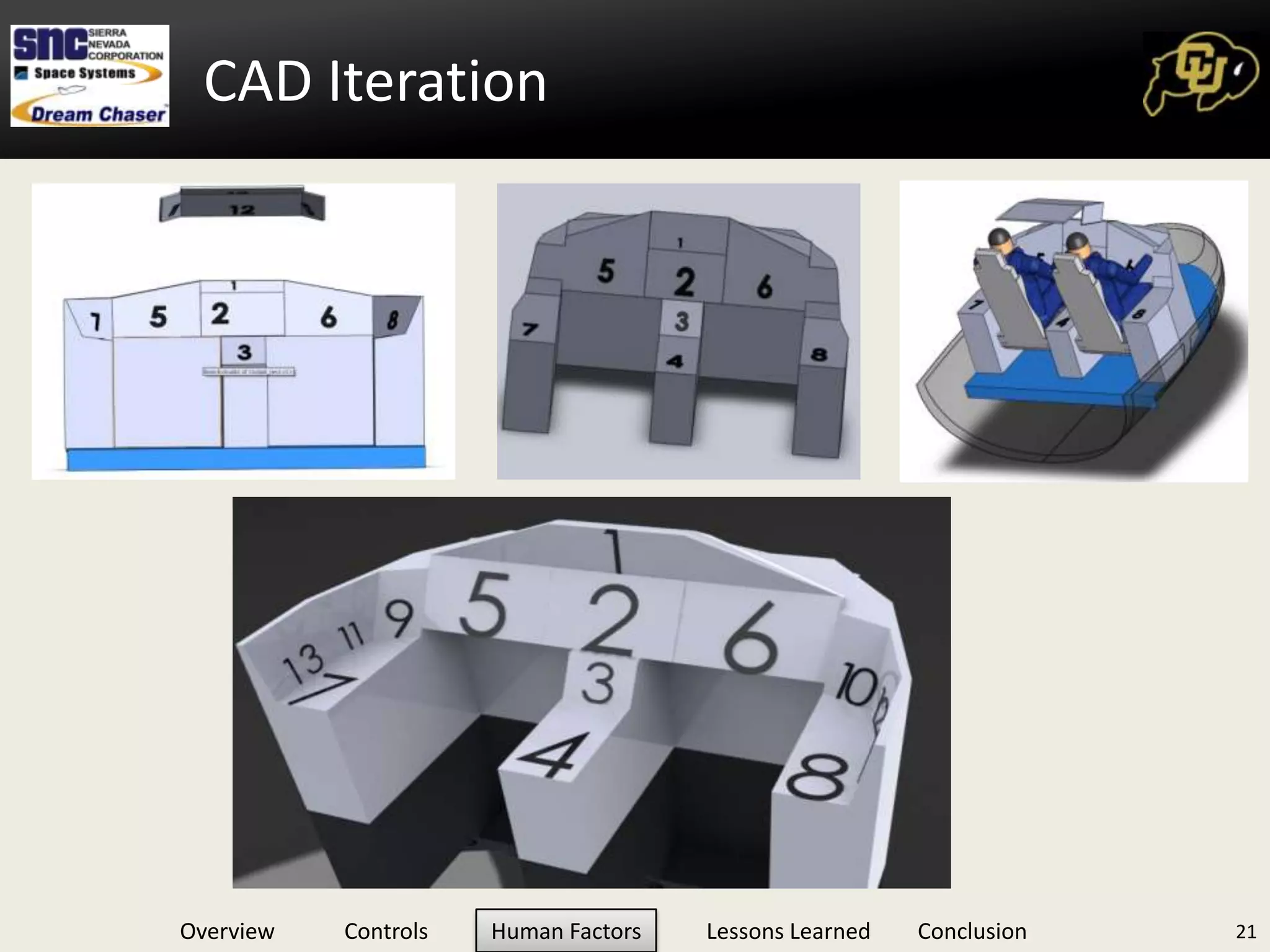

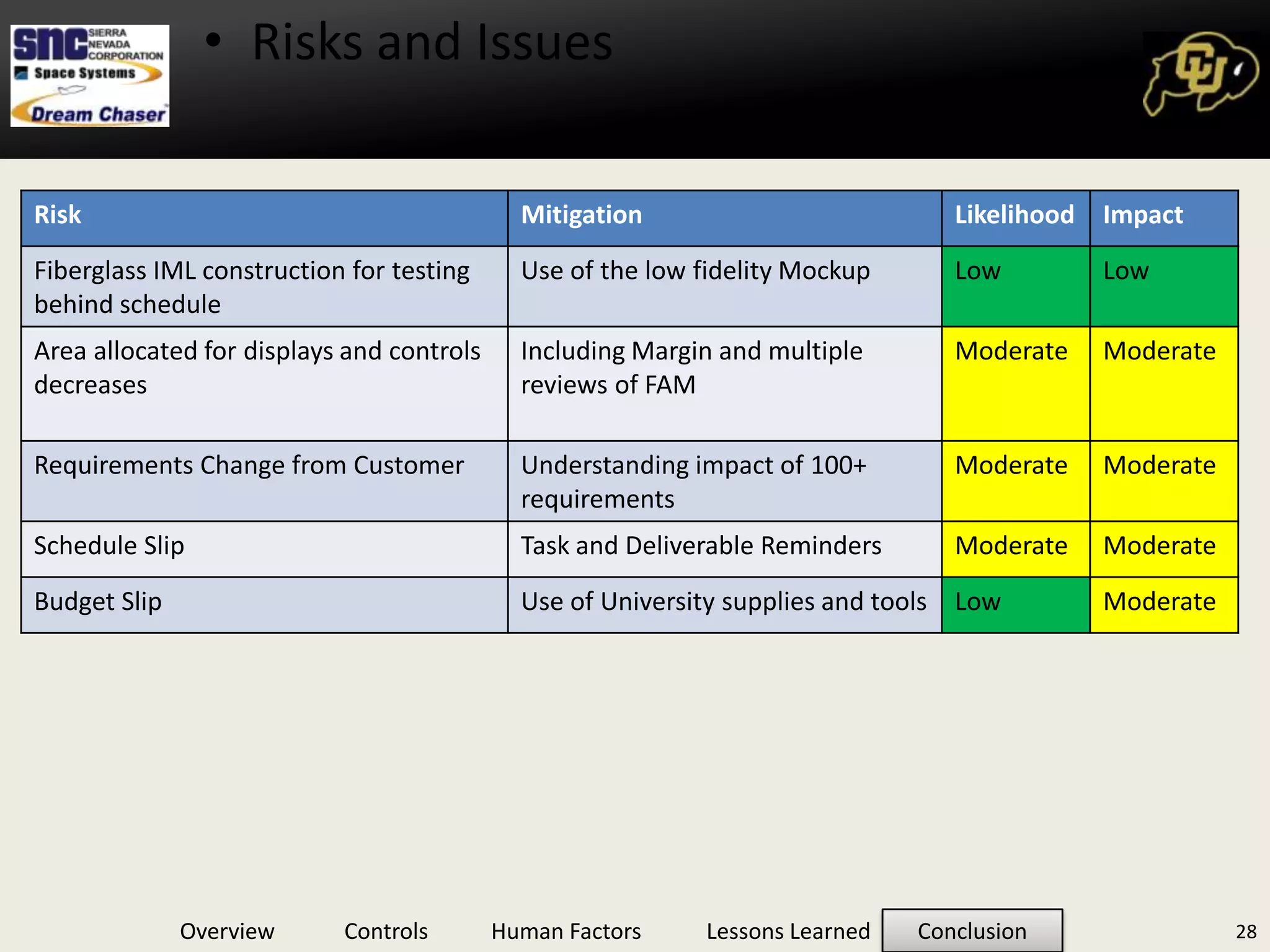

The document summarizes lessons learned from designing a spacecraft cockpit. It discusses starting the design process from scratch with limited knowledge, conducting literature research and technology evaluations. Trade studies were performed to evaluate options for vehicle control and control placement. Mockups and evaluations with human factors experts were used to iterate the design. Key lessons included focusing on critical items, knowing when further iteration isn't needed, considering secondary human factors, and keeping track of lessons learned.