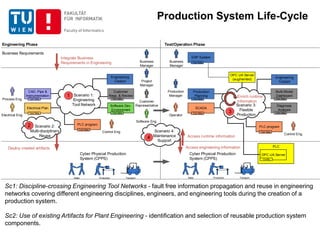

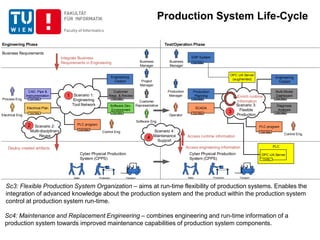

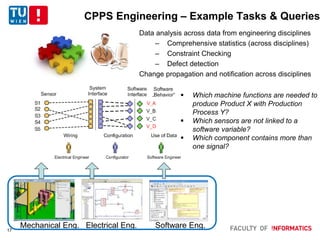

The document discusses the application of semantic web technologies (SWT) in the context of Industry 4.0, particularly in enhancing flexible production systems and processes through cyber-physical systems (CPS). It outlines various scenarios where SWT can support multi-disciplinary engineering, highlighting the complexity of data integration across diverse engineering fields. Additionally, it identifies challenges in the application of SWT and the need for improved tools and knowledge management to fully exploit its potential in engineering contexts.

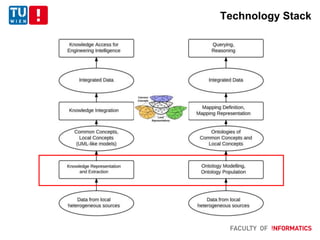

![Data Integration Solution

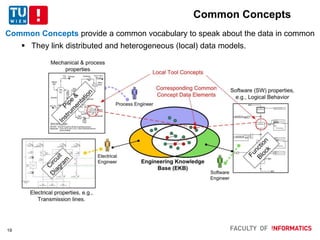

Ontology Based Information

Integration (OBII) Approach

Integration of data from

heterogeneous sources using

[Cal01, Wac01].

Three components of the OBII

approach:

– (1) Local ontologies - to

represent data specific to a data

source.

– (2) A common ontology - to

represent the aggregation of

relevant concepts

– (3) The mapping between local

ontologies and the common

ontology.

PLC Tool

Database

Client’s Electrical

Requirement

Spreadsheet

MCAD Tool

XML Export

Local Ontology

(Software)

Local Ontology

(Electrical)

Local Ontology

(Mechanical)

Common Ontology

(Power Plant)

ECAD Tool

Database

Lifting schema and data into local ontologies

Mapping between common and local ontologies

2

1

3](https://image.slidesharecdn.com/sssw16semweb4i40forweb-160721072840/85/Semantic-Web-for-Advanced-Engineering-20-320.jpg)