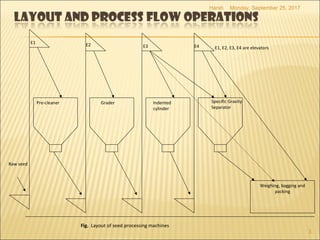

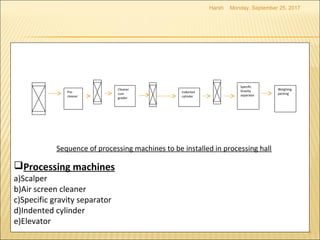

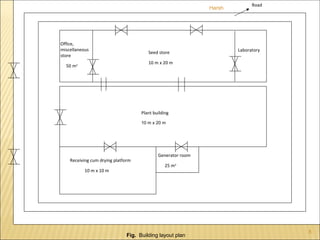

The document describes the design and components of a seed processing plant. The plant is designed based on the characteristics of the seed grain and impurities that need to be separated. The capacity of the plant depends on the capacity of the seed cleaner, which is the main machine. Other machines also work to separate materials based on differences in seed and impurity characteristics. These additional machines are matched to the cleaner's capacity for effective utilization. The plant building includes a receiving-cum-drying platform, processing area, and auxiliary building. Key processing machines include a scalper, air screen cleaner, specific gravity separator, indented cylinder, and elevator.