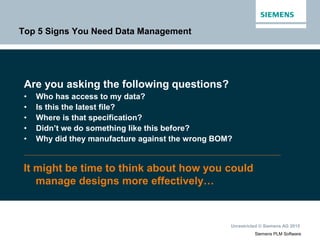

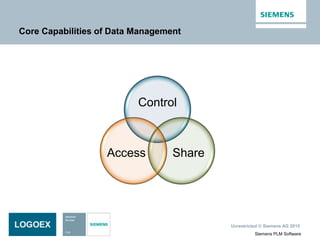

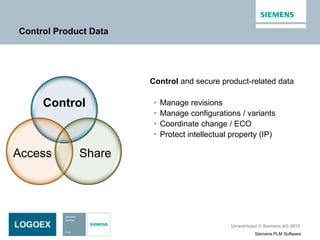

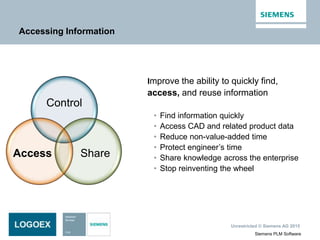

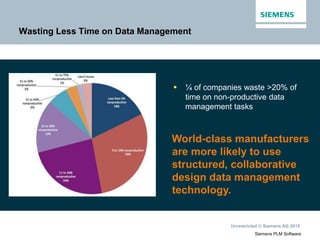

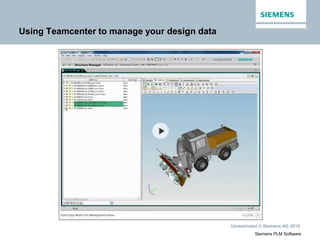

This document discusses efficient design data management. It begins by outlining signs that a company needs improved data management, such as not knowing who has access to data or manufacturing incorrect products. It then discusses how world-class companies effectively manage data through tools that control, share, and provide access to product information. Specific capabilities covered include revision management and intellectual property protection. The document advocates that data management offers business value through improved productivity and quality. It profiles example customers and outlines the low total cost of ownership of relevant solutions from Siemens PLM Software.