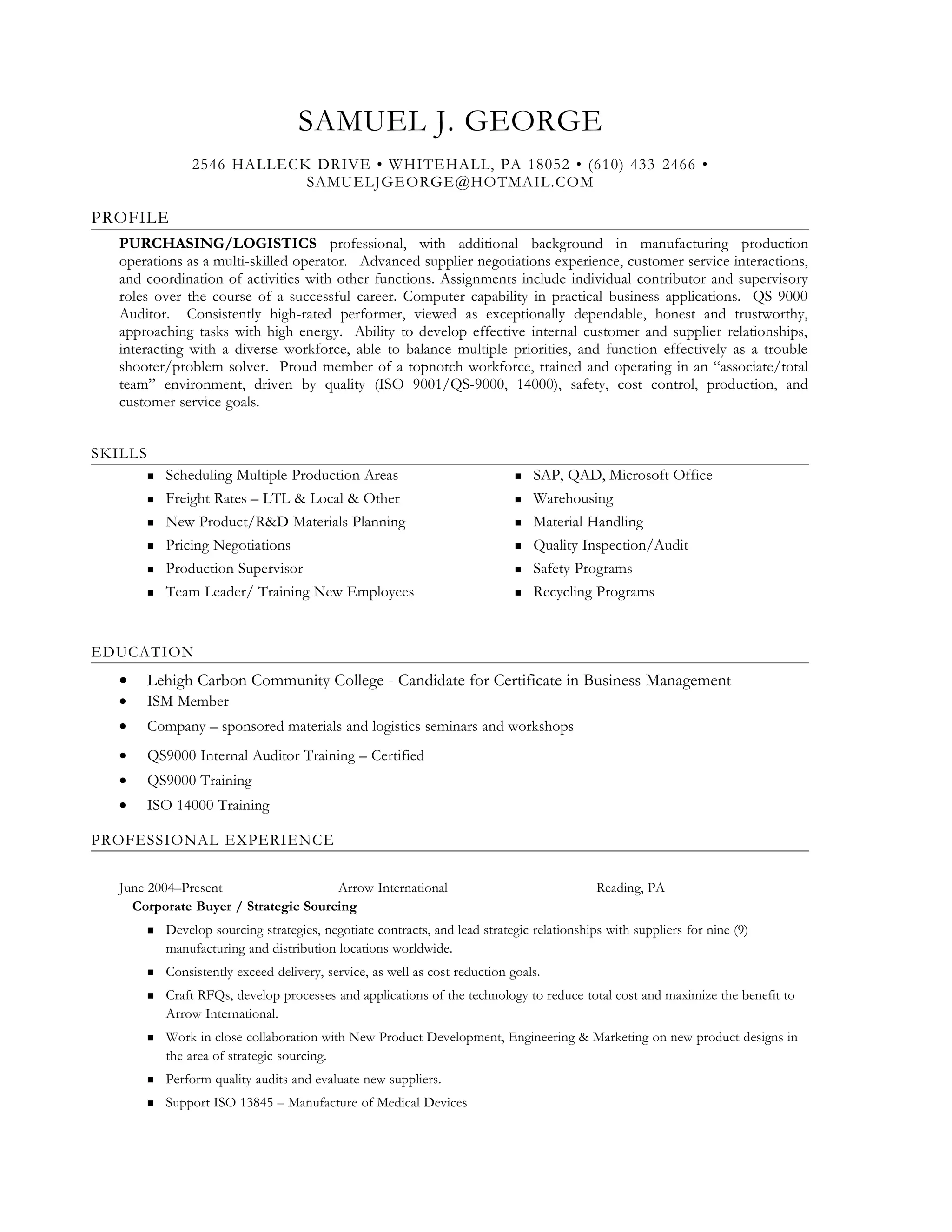

This document is a resume for Samuel J. George highlighting his experience in purchasing, logistics, and production operations over 30 years. It summarizes his roles coordinating supplier negotiations and relationships, scheduling production, negotiating freight rates, and implementing quality and safety programs. His most recent role is as a Corporate Buyer and Strategic Sourcing manager at Arrow International where he leads relationships with global suppliers and exceeds cost reduction goals.