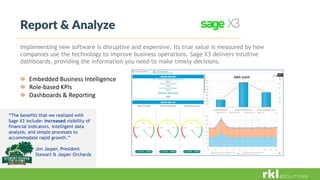

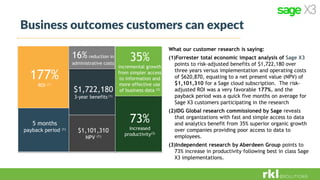

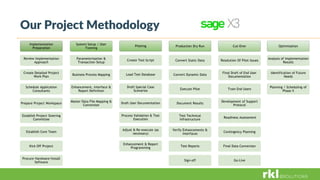

This document summarizes information about RKL eSolutions, LLC and their software solutions for food processors built on Sage. Key points include that RKL has over 1300 Sage customers across 43 states and 102 colleagues nationwide. Sage is also summarized, noting they have 37 years of experience serving over 3 million customers in 23 countries with $3 billion in global revenue. The document then discusses RKL's award-winning services, technologies, and solutions for meeting regulatory compliance, managing inventory, production planning and tracking, and business intelligence/analytics. Case studies show benefits customers have experienced including increased growth and productivity. RKL's implementation methodology is outlined in 6 phases from preparation to optimization. The RKL Sage X3 project team is introduced with specific