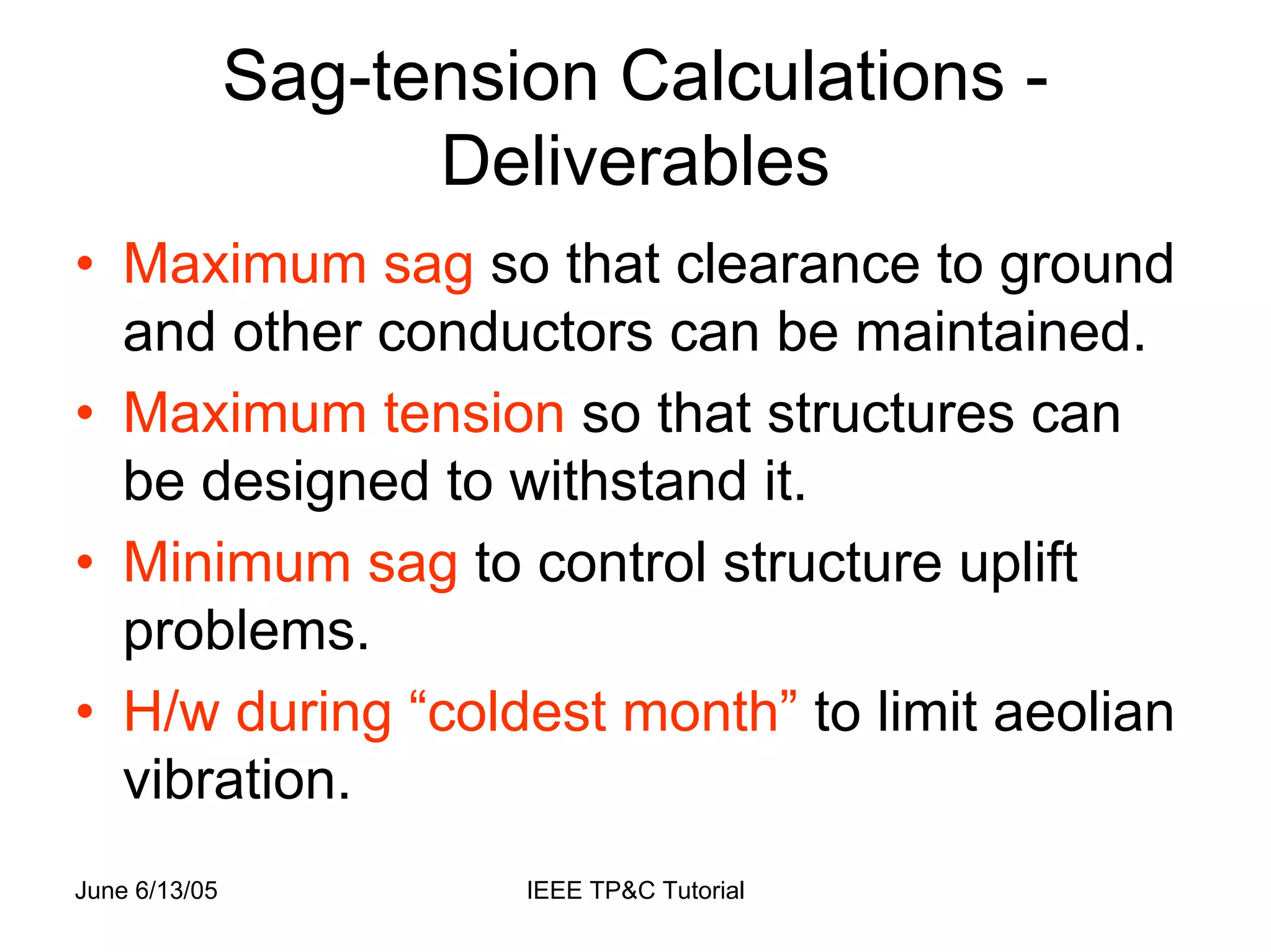

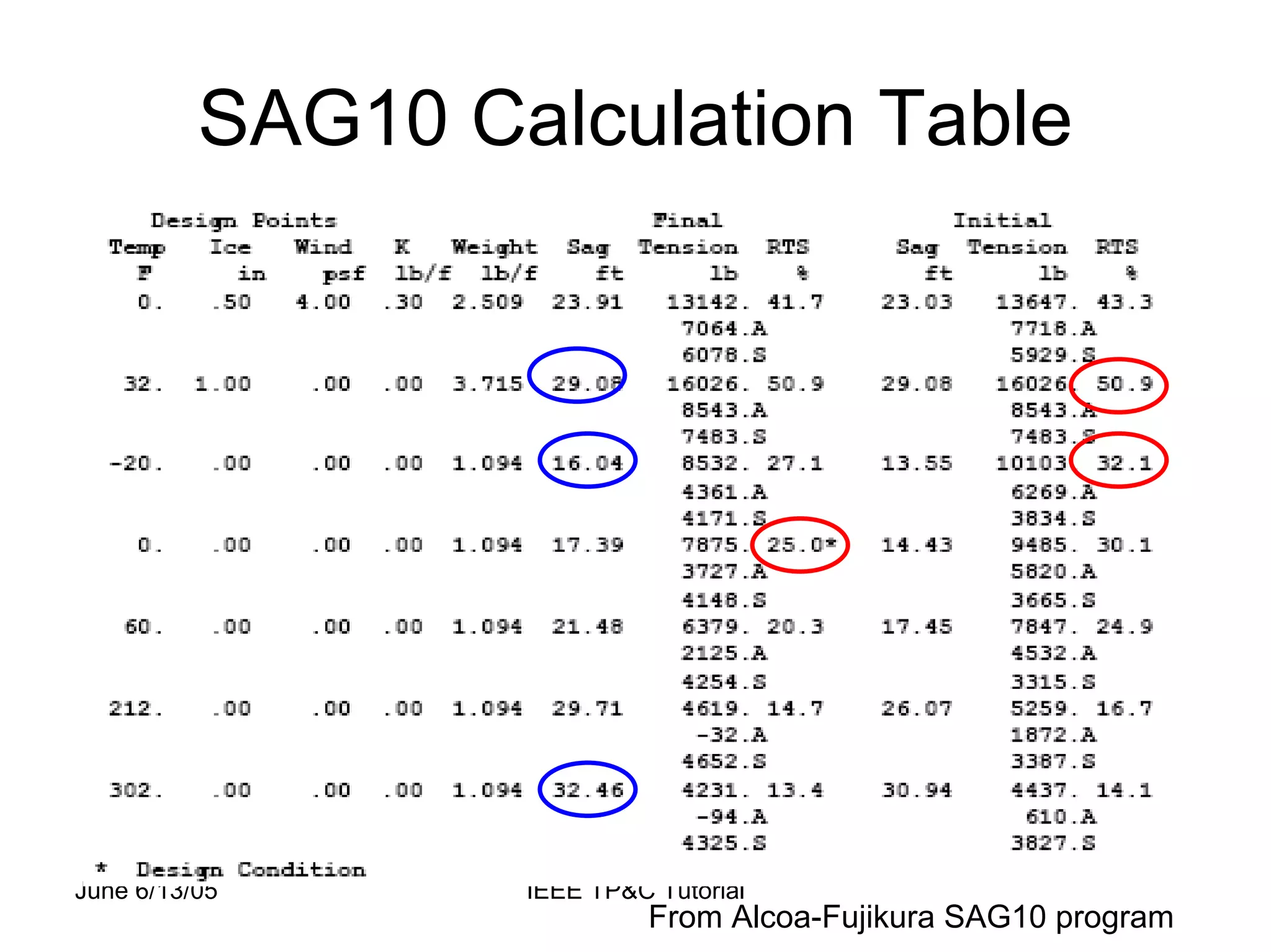

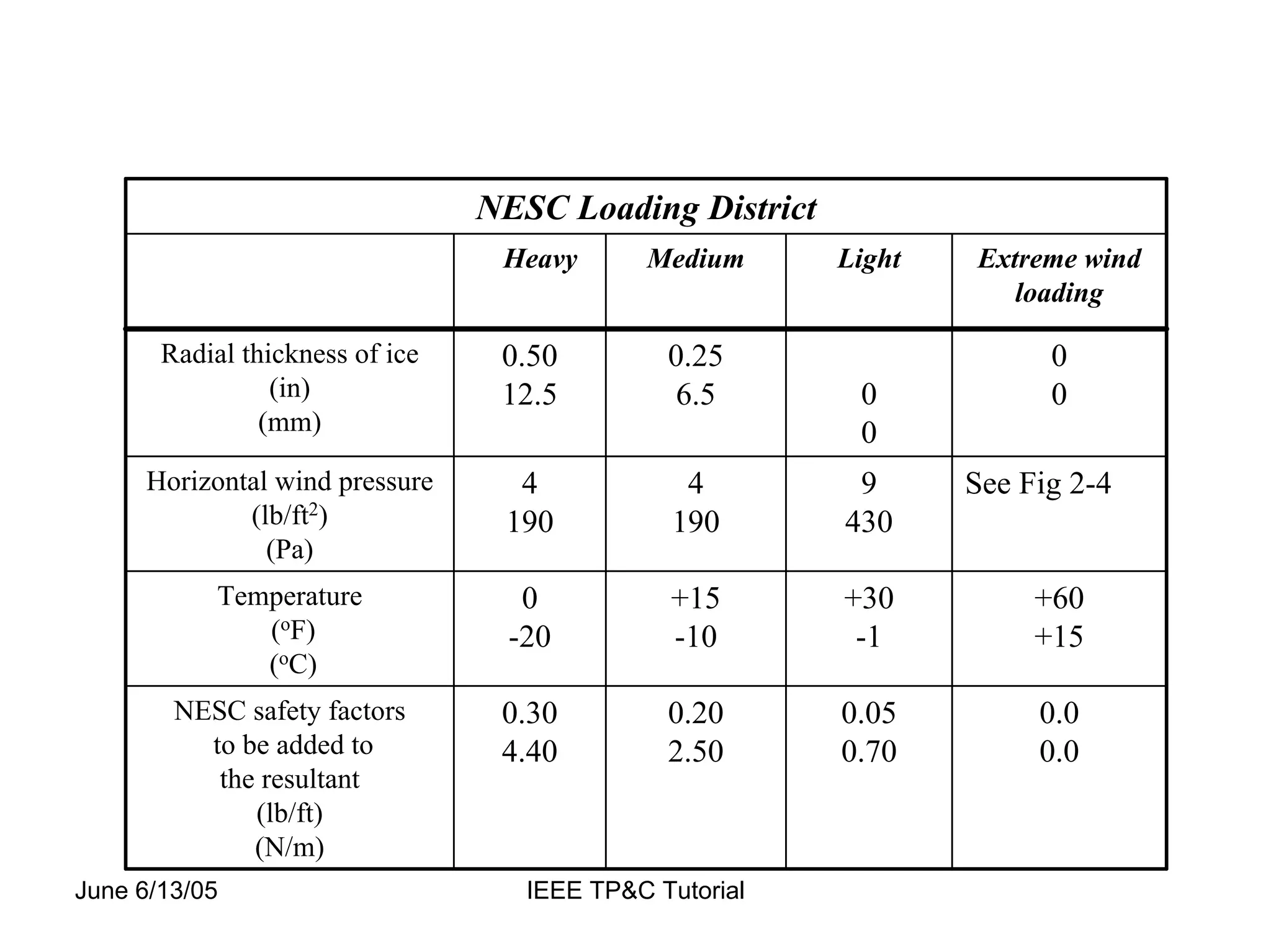

This document provides an overview of sag-tension calculations for overhead power lines. It discusses key concepts like the catenary curve, ruling span, conductor weight changes from ice and temperature, and tension limits. The tutorial covers how sag and tension are affected by various factors and outlines important references for sag-tension calculations. It aims to explain the fundamentals and deliverables of sag-tension analysis to help design overhead lines that maintain safety clearances while preventing excessive sag or tension.

![June 6/13/05 IEEE TP&C Tutorial

5,000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

0.000 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.400 0.450

% Strain

5,000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

0.000 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.400 0.450

100

200

300

0.000 0.050 0.100 0.150 0.200 0.250 0.300 0.350 0.400 0.450

Stress

[MPa]

% Strain

Stress-Strain Test

30% RBS30% RBS

50% RBS50% RBS

70% RBS70% RBS

One Hour

Modulus

Final

Modulus

Initial

Modulus

0

Courtesy of Southwire Corp.](https://image.slidesharecdn.com/sag-tensioncalculationsatutorialdeve-201219093746/75/Sag-tension-calculations-a_tutorial_deve-22-2048.jpg)