S-000-1670-0001V_0_0001 field Quality control.pdf

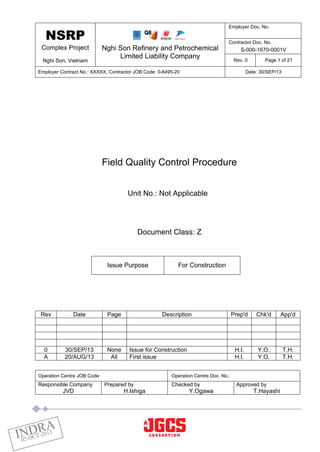

- 1. NSRP Complex Nghi S Employer Contract No.: XXXXX, Contractor JOB Code: 0 Rev 0 A Operation Centre JOB Code: Responsible Company NSRP Complex Project Son, Vietnam Employer Contract No.: XXXXX, Contractor JOB Code: 0 Date 30/SEP/13 20/AUG/13 Operation Centre JOB Code: Responsible Company JVD Project , Vietnam Nghi Son Employer Contract No.: XXXXX, Contractor JOB Code: 0 Page 30/SEP/13 None /13 All Operation Centre JOB Code: Responsible Company Prepared Field Issue Purpose Nghi Son Refinery and Petrochemical Limited Liability Company Employer Contract No.: XXXXX, Contractor JOB Code: 0 Page None Issue for Construction All First issue Prepared by H.Ishiga Field Quality Control Procedure Unit No.: Document Class: Issue Purpose Refinery and Petrochemical Limited Liability Company Employer Contract No.: XXXXX, Contractor JOB Code: 0-6495- Description Issue for Construction First issue Operation Centre H.Ishiga Checked Quality Control Procedure Unit No.: Not Applicable Document Class: Issue Purpose Refinery and Petrochemical Limited Liability Company -20 Description Issue for Construction Operation Centre Checked by Y.Ogawa Quality Control Procedure Not Applicable Document Class: Z For Construction Refinery and Petrochemical Employer Doc. No. Contractor Doc. No. Prep'd Operation Centre Doc. No.: Y.Ogawa Quality Control Procedure Not Applicable Construction Employer Doc. No. Contractor Doc. No. S-000-1670 Rev. 0 Date: 30 Prep'd Chk'd H.I. Y.O. H.I. Y.O. Doc. No.: Approved by T.Hayashi Quality Control Procedure Employer Doc. No. Contractor Doc. No. 670-0001V Page 1 of 21 30/SEP/13 Chk'd App'd Y.O. T.H. Y.O. T.H. Approved by T.Hayashi 21 App'd T.H. T.H. INDRA 02-OCT-2013

- 2. NSRP Title: Field Quality Control Procedure 1 GENERAL 1.1 Scope 1.2 Purpose 1.3 Objective 2 ABBREVIATION AND DEF 3 REFERENCES 4 PROJECT STANDA 5 INSPECTION AND TEST 6 ORGANIZATION 6.1 Field 6.2 QC E 6.3 Inspector 6.4 Qualification of QC Personnel 7 REGULAR QUALITY CONT 7.1 Issuance of QC specifications 7.2 Kick 7.3 Review and Approval of Subcontractor’s documents 7.4 Pre 7.5 Material Receiving Inspection 7.6 Material Identification and Traceability 7.7 QC 7.8 Notification for Witness Inspection.................................................................................... 7.9 Witness Insp 7.10 Disposition (Correction) and Corrective action of Nonconformity 7.11 C 7.12 System Handov 8 LIAISON WITH 8.1 Meeting 8.2 Reporting 8.3 Notification A TTACHMENT ATTACHMENT NSRP Complex Field Quality Control Procedure GENERAL................................ Scope................................ Purpose................................ Objective................................ ABBREVIATION AND DEF REFERENCES PROJECT STANDA INSPECTION AND TEST ORGANIZATION Field QC Manager QC Engineer Inspector................................ Qualification of QC Personnel REGULAR QUALITY CONT Issuance of QC specifications Kick-off Meetings (After contract) Review and Approval of Subcontractor’s documents Pre-Inspection Meeting (PIM) Material Receiving Inspection Material Identification and Traceability QC Monitoring 7.8 Notification for Witness Inspection.................................................................................... Witness Insp Disposition (Correction) and Corrective action of Nonconformity Confirmation and Control of QC Record 7.12 System Handov LIAISON WITH Meeting................................ Reporting................................ Notification TTACHMENT-1 FIELD QC ORGANIZATIO ATTACHMENT-2 A LIST OF ANTICIPATE Complex Project Field Quality Control Procedure ................................ ................................ ................................ ................................ ABBREVIATION AND DEF REFERENCES................................ PROJECT STANDARD QC PROCEDURES AND INSPECTION AND TEST ORGANIZATION................................ Manager ................................ ngineer…………………………………………………………………………………………… ................................ Qualification of QC Personnel REGULAR QUALITY CONT Issuance of QC specifications off Meetings (After contract) Review and Approval of Subcontractor’s documents Inspection Meeting (PIM) Material Receiving Inspection Material Identification and Traceability Monitoring................................ 7.8 Notification for Witness Inspection.................................................................................... Witness Inspection/Document Review Disposition (Correction) and Corrective action of Nonconformity onfirmation and Control of QC Record 7.12 System Handover........................................................................................................................... LIAISON WITH EMPLOYER ................................ ................................ Notification................................ FIELD QC ORGANIZATIO A LIST OF ANTICIPATE Field Quality Control Procedure ................................................................ ................................................................ ................................................................ ................................................................ ABBREVIATION AND DEFINITION ................................................................ RD QC PROCEDURES AND INSPECTION AND TEST PLAN (ITP) ................................ ................................ …………………………………………………………………………………………… ................................................................ Qualification of QC Personnel ................................ REGULAR QUALITY CONTROL ACTIVITIES IN CO Issuance of QC specifications................................ off Meetings (After contract) Review and Approval of Subcontractor’s documents Inspection Meeting (PIM)................................ Material Receiving Inspection ................................ Material Identification and Traceability ................................................................ 7.8 Notification for Witness Inspection.................................................................................... ection/Document Review Disposition (Correction) and Corrective action of Nonconformity onfirmation and Control of QC Record er........................................................................................................................... EMPLOYER ................................ ................................................................ ................................................................ ................................................................ FIELD QC ORGANIZATIO A LIST OF ANTICIPATED CONTENTS ................................ ................................................................ ................................ ................................ INITION................................ ................................ RD QC PROCEDURES AND PLAN (ITP)................................ ................................................................ ................................................................ …………………………………………………………………………………………… ................................ ................................ ROL ACTIVITIES IN CO ................................ off Meetings (After contract)................................ Review and Approval of Subcontractor’s documents ................................ ................................ Material Identification and Traceability................................ ................................ 7.8 Notification for Witness Inspection.................................................................................... ection/Document Review................................ Disposition (Correction) and Corrective action of Nonconformity onfirmation and Control of QC Record ................................ er........................................................................................................................... ................................ ................................ ................................ ................................ FIELD QC ORGANIZATION…………………………………………………… D ITPs…………………………………………………… Employer Doc. No. Contractor Doc. No. S CONTENTS ................................................................ ................................ ................................................................ ................................................................ ................................................................ ................................................................ RD QC PROCEDURES AND SPECIFICATIONS ................................................................ ................................................................ ................................ …………………………………………………………………………………………… ................................................................ ................................................................ ROL ACTIVITIES IN CONSTRUCTION PHASE ................................................................ ................................................................ Review and Approval of Subcontractor’s documents ................................ ................................................................ ................................................................ ................................ ................................................................ 7.8 Notification for Witness Inspection.................................................................................... ................................ Disposition (Correction) and Corrective action of Nonconformity ................................ er........................................................................................................................... ................................................................ ................................................................ ................................................................ ................................................................ …………………………………………………… …………………………………………………… Employer Doc. No. Contractor Doc. No. S-000-1670-0001V ................................ ................................................................ ................................................................ ................................................................ ................................ ................................ SPECIFICATIONS ................................ ................................ ................................................................ …………………………………………………………………………………………… ................................................................ ................................ NSTRUCTION PHASE ................................ ................................ ................................ ................................................................ ................................ ................................................................ ................................ 7.8 Notification for Witness Inspection.................................................................................... ................................................................ Disposition (Correction) and Corrective action of Nonconformity................................ ................................................................ er........................................................................................................................... ................................................................ ................................................................ ................................................................ ................................ …………………………………………………… …………………………………………………… Contractor Doc. No. 0001V ................................................................ ................................ ................................ ................................ ................................................................ ................................................................ SPECIFICATIONS................................ ............................................................... ................................................................ ...................................................... …………………………………………………………………………………………… ................................ ................................................................ NSTRUCTION PHASE.............................. ................................................................ ................................................................ ................................................................ ................................ ................................................................ .......................................................... ................................................................ 7.8 Notification for Witness Inspection.................................................................................... ........................................................... ................................ ....................................................... er........................................................................................................................... ................................ ................................ ................................ ................................................................ ……………………………………………………………………10 …………………………………………………… Rev.0 Page 2 of 21 PAGE ................................... .................................................... ................................................ .............................................. ................................ ..................................... .......................................... ............................... ................................ ...................... ……………………………………………………………………………………………... .............................................. ......................................... .............................. ......................................... ................................ ................................ ........................................... ......................................... .......................... ..................................... 7.8 Notification for Witness Inspection...................................................................................................8 ........................... ........................................... ....................... er................................................................................................................................9 .............................................. ................................................. ............................................. .......................................... ………………10 ……………………………………………………….……….11 21 PAGE ... 4 ....................4 ................4 ..............4 ..................................4 .....5 ..........5 ...............................5 ..................................5 ...................... 5 ...5 ..............6 .........6 ..............................6 .........6 ...................................6 ................................6 ...........6 .........7 ..........................7 .....7 ...............8 ...........................8 ...........8 .......................8 .....9 ..............9 .................9 .............9 ..........9 ………………10 ……….11 INDRA 02-OCT-2013

- 3. NSRP Title: Field Quality Control Procedure ATTACHMENT ATTACHMENT ATTACHMENT NSRP Complex Field Quality Control Procedure ATTACHMENT-3 A TABLE OF ANTICIPAT ATTACHMENT-4 NOTIFICATION ATTACHMENT-5 DOCUMENT FLOW Complex Project Field Quality Control Procedure A TABLE OF ANTICIPAT NOTIFICATION DOCUMENT FLOW Field Quality Control Procedure A TABLE OF ANTICIPATED QCR NOTIFICATION FOR INSPECTION DOCUMENT FLOW…………………………………………………… ED QCRs………………..……………………………… FOR INSPECTION FORM …………………………………………………… Employer Doc. No. Contractor Doc. No. S ………………..……………………………… FORM… …………………………………………….19 …………………………………………………… Employer Doc. No. Contractor Doc. No. S-000-1670-0001V ………………..……………………………… …………………………………………….19 …………………………………………………… Contractor Doc. No. 0001V ………………..……………………………… …………………………………………….19 ………………………………………………………………………………20 Rev.0 Page 3 of 21 ………………..………………………………………….1 …………………………………………….19 …………………………20 21 ………….13 …………………………………………….19 …………………………20 INDRA 02-OCT-2013

- 4. NSRP Title: Field Quality Control Procedure 1 1.1 1.2 1.3 2 NSRP Complex Field Quality Control Procedure GENERAL Scope This Field Quality Control Procedure activities for This procedure covers planning, administration, and execution of project Quality Control at construction site “Project Quality Plan ( Purpose The purpose of this procedure is to define the way for execution, responsibilities and interface between the Objective The objective of this procedure is to maintain Control Activities by all parties and personnel involved. The objectives of Quality C Only accepted facilities by co No defects / troubles / nonconformities Successful budget and schedule. 2 ABBREVIATION AND DEF Employer: Contractor: Subcontractor: JVD: FQCM: PQCM: KOM: PIM: ITP: NDE: QCR: WPS/PQR: NCR: Complex Project Field Quality Control Procedure GENERAL Quality Control Procedure activities for construction work This procedure covers planning, administration, and execution of project Quality Control at construction site. This document is based on the Quality Plan (Co The purpose of this procedure is to define the way for execution, responsibilities and interface between the Contractor The objective of this procedure is to maintain Control Activities by all parties and personnel involved. The objectives of Quality C nly accepted facilities by co No defects / troubles / nonconformities uccessful completion of construction and commissioning work will be achieved within agreed budget and schedule. ABBREVIATION AND DEF : Subcontractor: WPS/PQR: Field Quality Control Procedure Quality Control Procedure construction work for NSRP Complex This procedure covers planning, administration, and execution of project Quality Control . This document is based on the Common)”and The purpose of this procedure is to define the way for execution, responsibilities and interface Contractor, Employer and Subcontractor for Quality Control The objective of this procedure is to maintain Control Activities by all parties and personnel involved. The objectives of Quality Control for construction work are that; nly accepted facilities by contract documents will be delivered to No defects / troubles / nonconformities completion of construction and commissioning work will be achieved within agreed budget and schedule. – “First Time, Right ABBREVIATION AND DEFINITION : Nghi Son Refinery and Petrochemical Limites Liability Company : A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Engineering & Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. : The person, firm or corporation to whom the : Joint Venture Directorate Field QC : Project QC Manager : Kick-off Meeting : Pre-inspection Meeting : Inspection and Test Plan : Non Destructive Examination Quality Control Record : Welding Procedure Specification/Procedure : Nonconformity Report Quality Control Procedure describes the procedure for Contractor’s Quality Control (QC) NSRP Complex This procedure covers planning, administration, and execution of project Quality Control . This document is based on the and S-000-1610 The purpose of this procedure is to define the way for execution, responsibilities and interface and Subcontractor for Quality Control The objective of this procedure is to maintain the Control Activities by all parties and personnel involved. ntrol for construction work are that; ntract documents will be delivered to No defects / troubles / nonconformities will be detected in completion of construction and commissioning work will be achieved within agreed Time, Right” INITION Nghi Son Refinery and Petrochemical Limites Liability Company A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Engineering & Construction Corporation, SK Engineering & Construction Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. The person, firm or corporation to whom the Joint Venture Directorate Field QC Manager Project QC Manager off Meeting inspection Meeting Inspection and Test Plan Non Destructive Examination Quality Control Record Welding Procedure Specification/Procedure Nonconformity Report Employer Doc. No. Contractor Doc. No. S describes the procedure for Contractor’s Quality Control (QC) NSRP Complex Project. This procedure covers planning, administration, and execution of project Quality Control . This document is based on the Quality Plan 1610-0001V “Construction Execution Plan The purpose of this procedure is to define the way for execution, responsibilities and interface and Subcontractor for Quality Control the uniformity and consistency of Contractor’s Quality Control Activities by all parties and personnel involved. ntrol for construction work are that; ntract documents will be delivered to will be detected in completion of construction and commissioning work will be achieved within agreed under good Quality Control. Nghi Son Refinery and Petrochemical Limites Liability Company A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Construction Corporation, SK Engineering & Construction Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. The person, firm or corporation to whom the Joint Venture Directorate Project QC Manager inspection Meeting Inspection and Test Plan Non Destructive Examination Quality Control Record Welding Procedure Specification/Procedure Nonconformity Report Employer Doc. No. Contractor Doc. No. S-000-1670-0001V describes the procedure for Contractor’s Quality Control (QC) This procedure covers planning, administration, and execution of project Quality Control Quality Plan described in S Construction Execution Plan The purpose of this procedure is to define the way for execution, responsibilities and interface and Subcontractor for Quality Control uniformity and consistency of Contractor’s Quality ntrol for construction work are that; ntract documents will be delivered to Employer will be detected in the facilities delivered. completion of construction and commissioning work will be achieved within agreed under good Quality Control. Nghi Son Refinery and Petrochemical Limites Liability Company A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Construction Corporation, SK Engineering & Construction Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. The person, firm or corporation to whom the Subcontract Welding Procedure Specification/Procedure Qualification Record Contractor Doc. No. 0001V describes the procedure for Contractor’s Quality Control (QC) This procedure covers planning, administration, and execution of project Quality Control described in S-000- Construction Execution Plan The purpose of this procedure is to define the way for execution, responsibilities and interface and Subcontractor for Quality Control of construction work uniformity and consistency of Contractor’s Quality Employer. facilities delivered. completion of construction and commissioning work will be achieved within agreed under good Quality Control. Nghi Son Refinery and Petrochemical Limites Liability Company A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Construction Corporation, SK Engineering & Construction Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. Subcontract Qualification Record Rev.0 Page 4 of 21 describes the procedure for Contractor’s Quality Control (QC) This procedure covers planning, administration, and execution of project Quality Control activities -1139-0004V Construction Execution Plan”. The purpose of this procedure is to define the way for execution, responsibilities and interface construction work. uniformity and consistency of Contractor’s Quality facilities delivered. completion of construction and commissioning work will be achieved within agreed Nghi Son Refinery and Petrochemical Limites Liability Company A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Construction Corporation, SK Engineering & Construction Co.,Ltd, Technip France and Technip Geoproduction (m) Sdn.Bhd. is issued Qualification Record 21 describes the procedure for Contractor’s Quality Control (QC) activities 04V uniformity and consistency of Contractor’s Quality completion of construction and commissioning work will be achieved within agreed A Joint Venture formed by JGC Corporation, Chiyoda Corporation, GS Construction Corporation, SK Engineering & Construction INDRA 02-OCT-2013

- 5. NSRP Title: Field Quality Control Procedure 3 4 5 6 6.1 6.2 NSRP Complex Field Quality Control Procedure 3 REFERENCES S-000-1670 S-000-1670 S-000-1670 S-000-1520 3550-8440 S-000-1139 S-000-1610 4 PROJECT STANDARD QC The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to ensure Quality of 5 INSPECTION AND TEST PLA Contractor requires construction activities to be inspected or examined with reference document and acceptance criteria for Contractor specifications described in S anticipated ITPs is as per [Attachment ORGANIZATION Field QC organization for the project is provided as per responsible for QC activities at construction site. Roles and responsibilities of each Field QC Manager Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will suppor construction work. QC Engineer(s) If necessary, FQCM will assign QC Engineers Activities under FQCM. They are also responsible for control of inspectors. Complex Project Field Quality Control Procedure REFERENCES 1670-0002V 1670-0003V 1670-0004V 520-0106V 8440-SP-0030 139-0004V 1610-0001V PROJECT STANDARD QC The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to ensure Quality of construction work at PECTION AND TEST PLA Contractor requires Subcontractor construction activities to be inspected or examined with reference document and acceptance criteria for Contractor’s approval. ITP shall identify all inspections and tests required specifications in the sequential described in S-000-1670 anticipated ITPs is as per [Attachment ORGANIZATION Field QC organization for the project is provided as per responsible for QC activities at construction site. Roles and responsibilities of each QC Manager Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will suppor construction work. ngineer(s) If necessary, FQCM will assign QC Engineers Activities under FQCM. They are also responsible for control of inspectors. Field Quality Control Procedure Quality Control Requirements Nonconformity Contr Material Control Positive Material Fabrication Project Construction Execution Plan PROJECT STANDARD QC PROCEDURES AND SPECI The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to construction work at PECTION AND TEST PLAN (ITP) Subcontractor to submit an Inspection and Test Plan (ITP) construction activities to be inspected or examined with reference document and acceptance criteria approval. ITP shall identify all inspections and tests required in the sequential manner of construction work 1670-0002V “Quality anticipated ITPs is as per [Attachment Field QC organization for the project is provided as per responsible for QC activities at construction site. Roles and responsibilities of each personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will suppor If necessary, FQCM will assign QC Engineers Activities under FQCM. They are also responsible for control of inspectors. Quality Control Requirements onconformity Contr Material Traceability Control Procedure Control of Monitoring Positive Materials Identification Fabrication and Erection Project Quality Plan ( Construction Execution Plan PROCEDURES AND SPECI The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to construction work at construction N (ITP) to submit an Inspection and Test Plan (ITP) construction activities to be inspected or examined with reference document and acceptance criteria approval. ITP shall identify all inspections and tests required manner of construction work Quality Control Requirements anticipated ITPs is as per [Attachment-2]. Field QC organization for the project is provided as per responsible for QC activities at construction site. personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will suppor If necessary, FQCM will assign QC Engineers(QCE) Activities under FQCM. They are also responsible for control of inspectors. Employer Doc. No. Contractor Doc. No. S Quality Control Requirements t onconformity Control Procedure Traceability Control Procedure f Monitoring and Measuring Devices, Identification and Erection Quality Plan (Common) Construction Execution Plan PROCEDURES AND SPECIFICATIONS The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to construction site. to submit an Inspection and Test Plan (ITP) construction activities to be inspected or examined with reference document and acceptance criteria approval. ITP shall identify all inspections and tests required manner of construction work Control Requirements Field QC organization for the project is provided as per [Attachment responsible for QC activities at construction site. personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will suppor (QCE). QCE are responsible for Quality Control Activities under FQCM. They are also responsible for control of inspectors. Employer Doc. No. Contractor Doc. No. S-000-1670-0001V to Subcontractor ol Procedure for Construction Work Traceability Control Procedure for Piping suring Devices, Identification (PMI) of Alloy Materials during Site ) FICATIONS The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to to submit an Inspection and Test Plan (ITP) construction activities to be inspected or examined with reference document and acceptance criteria approval. ITP shall identify all inspections and tests required manner of construction work. The detail requirements of ITP are Control Requirements to Subcontractor [Attachment-1]. personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, budget and schedule. Project QC Manager (PQCM) will support FQCM for Quality Control in QCE are responsible for Quality Control Activities under FQCM. They are also responsible for control of inspectors. Contractor Doc. No. 0001V o Subcontractor Construction Work or Piping Construction Work suring Devices, (PMI) of Alloy Materials during Site The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to to submit an Inspection and Test Plan (ITP) describing construction activities to be inspected or examined with reference document and acceptance criteria approval. ITP shall identify all inspections and tests required by the contract . The detail requirements of ITP are to Subcontractor ”. Field QC group is personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, t FQCM for Quality Control in QCE are responsible for Quality Control Activities under FQCM. They are also responsible for control of inspectors. Rev.0 Page 5 of 21 Construction Work Construction Work (PMI) of Alloy Materials during Site The documents which are listed in Section 3 will be utilized as project Standard Quality Control procedures and specifications. These documents are minimum requirements of Contractor to describing construction activities to be inspected or examined with reference document and acceptance criteria by the contract . The detail requirements of ITP are A list of Field QC group is personnel engaged in QC Activities are detailed as the below. Field QC Manager (FQCM) is responsible for all direction, definition and coordination in order to ensure that Quality Control Activities are completed in accordance with the Project specifications, t FQCM for Quality Control in QCE are responsible for Quality Control 21 Construction Work construction activities to be inspected or examined with reference document and acceptance criteria ensure that Quality Control Activities are completed in accordance with the Project specifications, INDRA 02-OCT-2013

- 6. NSRP Title: Field Quality Control Procedure 6.3 6.4 Qualification of QC Personnel All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to (1) First engagement of project site (2) Commencement of new insp (3) Upon Employer Contractor personnel such that QCRs cannot be completed or amended by unauthorised persons. Requirement of Subcont Control Requirements to Subcontractor 7 REGULAR QUALITY CONT 7.1 Issuance of QC specifications 7.2 7.3 7.4 NSRP Complex Field Quality Control Procedure Inspector Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Subcontractor’s activity from quality point of view, immediately, and coordination with Subcontractor to close any nonconformity. Qualification of QC Personnel All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to (1) First engagement of project site (2) Commencement of new insp (3) Upon Employer Contractor’s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. Requirement of Subcont Control Requirements to Subcontractor REGULAR QUALITY CONT Issuance of QC specifications FQCM prepare all project quality requirements. These documents are forwarded to applicable documents to 7.2 Kick-off Meetings (After FQCM may critical construction (1) To make sure were in charge of Subcontractor (2) To confirm that contract Subcontractor requirements. 7.3 Review and Approval of Field QC Team and Personnel Subcontractor Subcontractor before related activity is 7.4 Pre-Inspection Complex Project Field Quality Control Procedure Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Subcontractor’s activity from quality point of view, immediately, and coordination with Subcontractor to close any nonconformity. Qualification of QC Personnel All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to (1) First engagement of project site (2) Commencement of new insp (3) Upon Employer’s request s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. Requirement of Subcontractor QC personnel shall be addressed in S Control Requirements to Subcontractor REGULAR QUALITY CONT Issuance of QC specifications QCM prepares and issue all project quality requirements. These documents are forwarded to applicable documents to off Meetings (After may participate in Kick construction after To make sure Subcontractor n charge of th Subcontractor’s Project Manager To confirm that Subcontractor contract, understand Subcontractor will start the requirements. Review and Approval of Team reviews and Personnel Qualification, Subcontractor. Subcontractor is requested to submit these documents before related activity is Inspection Meeting (PIM) Field Quality Control Procedure Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Subcontractor’s activity from quality point of view, immediately, and coordination with Subcontractor to close any nonconformity. Qualification of QC Personnel All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to (1) First engagement of project site (2) Commencement of new inspection activity s request s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. ractor QC personnel shall be addressed in S Control Requirements to Subcontractor REGULAR QUALITY CONTROL ACTIVITIES IN Issuance of QC specifications and issues QC documents listed in section 3 all project quality requirements. These documents are forwarded to applicable documents to subcontract off Meetings (After contract) ticipate in Kick-off Meeting (KOM) with after its subcontract is placed Subcontractor’s Application Engineers / Sales Engineers, who their proposals, correctly transfer the requirements to ’s Project Manager Subcontractor’s Project Manager who actually execute the , understand project requirements correctly and to ensure will start the Subcontract Review and Approval of Subcontractor reviews Subcontractor Qualification, to ensure that the Project requirements are correctly documented by is requested to submit these documents before related activity is commenced. Meeting (PIM) Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Subcontractor’s activity from quality point of view, immediately, and coordination with Subcontractor to close any nonconformity. All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to ection activity s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. ractor QC personnel shall be addressed in S Control Requirements to Subcontractor”. ROL ACTIVITIES IN QC documents listed in section 3 all project quality requirements. These documents are forwarded to subcontract. off Meeting (KOM) with its subcontract is placed ’s Application Engineers / Sales Engineers, who proposals, correctly transfer the requirements to ’s Project Manager. ’s Project Manager who actually execute the requirements correctly and to ensure Subcontract based on the correct understanding of Subcontractor’s documents Subcontractor’s QC documents to ensure that the Project requirements are correctly documented by is requested to submit these documents commenced. Employer Doc. No. Contractor Doc. No. S Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Subcontractor’s activity from quality point of view, reporting any finding during inspection to FQCM immediately, and coordination with Subcontractor to close any nonconformity. All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. training for Contractor QC personnel at the following time, but not limited to s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. ractor QC personnel shall be addressed in S ROL ACTIVITIES IN CONSTRUCTION QC documents listed in section 3 all project quality requirements. These documents are forwarded to off Meeting (KOM) with Subcontractor its subcontract is placed. The purpose of KOM is as follows ’s Application Engineers / Sales Engineers, who proposals, correctly transfer the requirements to ’s Project Manager who actually execute the requirements correctly and to ensure based on the correct understanding of ’s documents ’s QC documents such as WPS/PQR, ITP, Method Statement, to ensure that the Project requirements are correctly documented by is requested to submit these documents early enough so that they are approved Employer Doc. No. Contractor Doc. No. S-000-1670-0001V Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection in accordance with Inspection and Test Plan (ITP) approved by Employer reporting any finding during inspection to FQCM immediately, and coordination with Subcontractor to close any nonconformity. All QC activities for construction work shall be implemented by competent QC personnel in each to keep acceptable quality level during all project period in construction. Contractor will develop the training for Contractor QC personnel at the following time, but not limited to s QC personnel shall be issued with Inspection Stamps that are unique to personnel such that QCRs cannot be completed or amended by unauthorised persons. ractor QC personnel shall be addressed in S-000 CONSTRUCTION PHASE QC documents listed in section 3. These documents include and reflect all project quality requirements. These documents are forwarded to Subcontractor Subcontractor, which . The purpose of KOM is as follows ’s Application Engineers / Sales Engineers, who proposals, correctly transfer the requirements to ’s Project Manager who actually execute the requirements correctly and to ensure that based on the correct understanding of such as WPS/PQR, ITP, Method Statement, to ensure that the Project requirements are correctly documented by early enough so that they are approved Contractor Doc. No. 0001V Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection Employer, monitoring of reporting any finding during inspection to FQCM immediately, and coordination with Subcontractor to close any nonconformity. All QC activities for construction work shall be implemented by competent QC personnel in each Contractor will develop the training for Contractor QC personnel at the following time, but not limited to. s QC personnel shall be issued with Inspection Stamps that are unique to a personnel such that QCRs cannot be completed or amended by unauthorised persons. 000-1670-0002V PHASE These documents include and reflect Subcontractor as parts of , which is held for major or . The purpose of KOM is as follows ’s Application Engineers / Sales Engineers, who proposals, correctly transfer the requirements to ’s Project Manager who actually execute the that based on the correct understanding of such as WPS/PQR, ITP, Method Statement, to ensure that the Project requirements are correctly documented by early enough so that they are approved Rev.0 Page 6 of 21 Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection , monitoring of reporting any finding during inspection to FQCM All QC activities for construction work shall be implemented by competent QC personnel in each party Contractor will develop the authorized QC personnel such that QCRs cannot be completed or amended by unauthorised persons. 0002V”Quality These documents include and reflect as parts of held for major or . The purpose of KOM is as follows : such as WPS/PQR, ITP, Method Statement, to ensure that the Project requirements are correctly documented by early enough so that they are approved 21 Inspection will be carried out by inspectors of Contractor. They are responsible for all field inspection reporting any finding during inspection to FQCM party Contractor will develop the QC These documents include and reflect such as WPS/PQR, ITP, Method Statement, to ensure that the Project requirements are correctly documented by INDRA 02-OCT-2013

- 7. NSRP Title: Field Quality Control Procedure 7.5 7.6 7.7 NSRP Complex Field Quality Control Procedure Pre-Inspection Meeting (PIM) otherwise agreed. confirm that Subcontractor PIM is final confirmation of construction work Requirement Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants before leaving submitted to Material Receiving I Material receiving inspection at construction warehouse shall be carried out by material in accordance with applicable specification. If found, Contractor Report (MER “Nonconformity Control Procedure Only materials accepted by the r construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. 6 Material Identification a Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S “Material Traceability All piping bulk materials supplied by Contractor shall be S-000-1360 including gaskets, stud bolts and nuts pre-fabrication, installation, and completion. Positive Material Identifi 3550-8440 Erection”to avoid 7.7 QC Monitoring Contractor organize periodical QC detail QC activity implemented at job site com monitoring (1) QC Personnel Control (2) QC Document Control (3) QC Record Control (4) NCR Control (5) Material Control (6) Welding Control Complex Project Field Quality Control Procedure Inspection Meeting (PIM) otherwise agreed. The confirm that Subcontractor PIM is final confirmation of construction work starts. Typical agenda of PIM is specified in S Requirements to Subcontractor Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants before leaving meeting. A copy of MOM will be distributed to relevant sections, as well as submitted to Employer. Material Receiving Inspection Material receiving inspection at construction warehouse shall be carried out by material accordance with applicable specification. If found, Contractor’s material control section will handle such MER )or Field QC section will issue NCR in onconformity Control Procedure Only materials accepted by the r construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. Material Identification a Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S Traceability Control Procedure for All piping bulk materials supplied by Contractor shall be 1360-0004V “Specification including gaskets, stud bolts and nuts fabrication, installation, and completion. Positive Material Identifi 8440-SP-0030 “Positive Material Identification to avoid misuse Monitoring Contractor organize periodical QC detail QC activity implemented at job site com includes, but not limited to, QC Personnel Control QC Document Control cord Control NCR Control Material Control Welding Control Field Quality Control Procedure Inspection Meeting (PIM) shall be conducted The PIM shall be conducted prior to the start of confirm that Subcontractor understand PIM is final confirmation of Subcontractor starts. Typical agenda of PIM is specified in S Subcontractor ”. Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as . nspection Material receiving inspection at construction warehouse shall be carried out by material accordance with applicable specification. If s material control section will handle such or Field QC section will issue NCR in onconformity Control Procedure for Only materials accepted by the receiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. Material Identification and Traceability Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S Control Procedure for All piping bulk materials supplied by Contractor shall be Specification for Identification including gaskets, stud bolts and nuts fabrication, installation, and completion. Positive Material Identification (PMI) is performed at Positive Material Identification misuse of welding consumable. Contractor organize periodical QC monitoring detail QC activity implemented at job site com includes, but not limited to, QC Personnel Control QC Document Control shall be conducted shall be conducted prior to the start of understands all the quality requirements specified in the Subcontractor’s understanding on project requirements before starts. Typical agenda of PIM is specified in S Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as Material receiving inspection at construction warehouse shall be carried out by material accordance with applicable specification. If any nonconformity, discrepancy s material control section will handle such or Field QC section will issue NCR in for Construction Work eceiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. nd Traceability Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S Control Procedure for Piping All piping bulk materials supplied by Contractor shall be or Identification including gaskets, stud bolts and nuts shall be checked by fabrication, installation, and completion. cation (PMI) is performed at Positive Material Identification of welding consumable. monitoring to Subcontractor to verify whether Subcontractor detail QC activity implemented at job site comply with includes, but not limited to, Employer Doc. No. Contractor Doc. No. S shall be conducted with Subcontractors for construction work unless shall be conducted prior to the start of the quality requirements specified in the ’s understanding on project requirements before starts. Typical agenda of PIM is specified in S Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as Material receiving inspection at construction warehouse shall be carried out by material any nonconformity, discrepancy s material control section will handle such or Field QC section will issue NCR in accordance Construction Work”. eceiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S Piping Construction Work All piping bulk materials supplied by Contractor shall be colour or Identification of Piping Materials shall be checked by colour cation (PMI) is performed at construction Positive Material Identification of Alloy mate of welding consumable. to Subcontractor to verify whether Subcontractor ply with project requirements. Employer Doc. No. Contractor Doc. No. S-000-1670-0001V with Subcontractors for construction work unless shall be conducted prior to the start of work. The Purpose of the quality requirements specified in the ’s understanding on project requirements before starts. Typical agenda of PIM is specified in S-000-1670 Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as Material receiving inspection at construction warehouse shall be carried out by material any nonconformity, discrepancy s material control section will handle such materials and issue accordance with S-000 eceiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to prevent unexpected damage, lost, deterioration, and substitution. Materials, parts, and components shall be clearly identified by marking, stencil, or throughout fabrication, field assembly and installation in accordance with S Construction Work”. colour coded in accordance with f Piping Materials”. Usage of correct materials colour coding throughout piping construction site in accordance with of Alloy materials during Site Fabrication and to Subcontractor to verify whether Subcontractor project requirements. Contractor Doc. No. 0001V with Subcontractors for construction work unless . The Purpose of the quality requirements specified in the subcontract ’s understanding on project requirements before 1670-0002V “Quality Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as Material receiving inspection at construction warehouse shall be carried out by material any nonconformity, discrepancy and/or and issue Material Ex 000-1670-00 eceiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to Materials, parts, and components shall be clearly identified by marking, stencil, or colour throughout fabrication, field assembly and installation in accordance with S-000-1670 coded in accordance with . Usage of correct materials coding throughout piping site in accordance with rials during Site Fabrication and to Subcontractor to verify whether Subcontractor project requirements. Each theme of QC Rev.0 Page 7 of 21 with Subcontractors for construction work unless . The Purpose of PIM is to subcontract. ’s understanding on project requirements before Quality Control Minutes of Meeting (MOM) for PIM should be completed, reviewed and signed by participants . A copy of MOM will be distributed to relevant sections, as well as Material receiving inspection at construction warehouse shall be carried out by material controller and/or damage are Material Exception 0003V eceiving inspection can be issued to Subcontractor for their construction work, and such materials shall be handled with proper storage and preservation to colour coding 1670-0004V coded in accordance with . Usage of correct materials coding throughout piping site in accordance with rials during Site Fabrication and to Subcontractor to verify whether Subcontractor’s Each theme of QC 21 with Subcontractors for construction work unless PIM is to . Control controller are ception coding . Usage of correct materials rials during Site Fabrication and s INDRA 02-OCT-2013

- 8. NSRP Title: Field Quality Control Procedure 7.8 7.9 7.10 7.11 C NSRP Complex Field Quality Control Procedure (7) NDE Control FQCM makes a plan in S-000-1670 against Subcontractor 7.8 Notification for Witness Contractor requires as specified in the approved ITP Witness items at site. In case that the inspection is planned required, such as the 7.9 Witness Inspection All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or Employer’s inspector in Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording approved by Contractor and Inspection record for the witness in completion of the inspection. In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. responsibility of submitting/coordinating to 7.10 Disposition When nonconformity is found during the construction, Contractor instructs Subcontractor to with such nonconformity in accordance with S for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Contractor for approval. approval on NCR by Subcontractor nonconformities. Confirmation and Control of QC Record All QC record developed system such as CMS and TOMAS. (1) Construction Management System (CMS) - Welding Status for Piping - NDE and PWHT Status for Piping - NDE Repair Ratio for Piping - Piping Test Package Status (2) Turnover Management System (TOMAS) - Inspection Status for All Categories except Piping - System Punch List Complex Project Field Quality Control Procedure NDE Control FQCM makes a plan in 1670-0002V “Quality Control against Subcontractor’s construction activity and its status. Notification for Witness Contractor requires Subcontractor as specified in the approved ITP Witness items and 2 working days In case that the inspection is planned such as the inspection itness Inspection / Document Review All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or s inspector in Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording by Contractor and Inspection record for the witness in completion of the inspection. In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. responsibility of submitting/coordinating to Disposition (Correction) When nonconformity is found during the construction, Contractor instructs Subcontractor to with such nonconformity in accordance with S for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Contractor for approval. approval on NCR by Contractor Subcontractor shall also take corrective actions to prevent recurrence of same or similar nonconformities. onfirmation and Control of QC Record All QC records with Contractor and/or developed system such as CMS and TOMAS. Construction Management System (CMS) Welding Status for Piping NDE and PWHT Status for Piping NDE Repair Ratio for Piping Piping Test Package Status Turnover Management System (TOMAS) Inspection Status for All Categories except Piping System Punch List Field Quality Control Procedure FQCM makes a plan in accordance Quality Control s construction activity and its status. Notification for Witness Inspection Subcontractor to submit the inspection notice for inspection and test activities as specified in the approved ITP 1 working day in advance for an inspection and 2 working days in advance for In case that the inspection is planned inspection and test Document Review All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or s inspector in accordance Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording by Contractor and Employer Inspection record for the witness inspection is reviewed and signed by the inspector soon after completion of the inspection. In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. responsibility of submitting/coordinating to (Correction) and Corrective When nonconformity is found during the construction, Contractor instructs Subcontractor to with such nonconformity in accordance with S for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Contractor for approval. Subcontractors shall perform correction Contractor. shall also take corrective actions to prevent recurrence of same or similar onfirmation and Control of QC Record ntractor and/or developed system such as CMS and TOMAS. Construction Management System (CMS) Welding Status for Piping NDE and PWHT Status for Piping NDE Repair Ratio for Piping Piping Test Package Status Turnover Management System (TOMAS) Inspection Status for All Categories except Piping System Punch List accordance with the detailed elements of QC Quality Control Requirements s construction activity and its status. Inspection to submit the inspection notice for inspection and test activities 1 working day in advance for an inspection in advance for In case that the inspection is planned out of job site and test at the piping Document Review All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or accordance with applicable ITP. Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording Employer. spection is reviewed and signed by the inspector soon after In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. responsibility of submitting/coordinating to Employer and Corrective Action of Nonconformity When nonconformity is found during the construction, Contractor instructs Subcontractor to with such nonconformity in accordance with S-000 for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Subcontractors shall perform correction shall also take corrective actions to prevent recurrence of same or similar onfirmation and Control of QC Record ntractor and/or Employer developed system such as CMS and TOMAS. T Construction Management System (CMS) NDE and PWHT Status for Piping Turnover Management System (TOMAS) Inspection Status for All Categories except Piping Employer Doc. No. Contractor Doc. No. S the detailed elements of QC equirements to Subcontractor s construction activity and its status. to submit the inspection notice for inspection and test activities 1 working day in advance for an inspection in advance for an inspection out of job site the piping pre-fabrication area All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or with applicable ITP. Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording spection is reviewed and signed by the inspector soon after In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. Employer of those documents. ction of Nonconformity When nonconformity is found during the construction, Contractor instructs Subcontractor to 000-1670-0003V for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Subcontractors shall perform correction shall also take corrective actions to prevent recurrence of same or similar Employer’s approval shall be The following data is controlled in each system. Inspection Status for All Categories except Piping Employer Doc. No. Contractor Doc. No. S-000-1670-0001V the detailed elements of QC monitoring Subcontractor”considering suitable time to submit the inspection notice for inspection and test activities 1 working day in advance for an inspection an inspection for Employer out of job site , Notification 1 week in advance is fabrication area All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording spection is reviewed and signed by the inspector soon after In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. of those documents. ction of Nonconformity When nonconformity is found during the construction, Contractor instructs Subcontractor to 0003V “Nonconformity Control Procedure for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to Subcontractors shall perform correction (implement disposition) only after shall also take corrective actions to prevent recurrence of same or similar shall be registered into Contractor he following data is controlled in each system. Contractor Doc. No. 0001V monitoring specified in 7. considering suitable time to submit the inspection notice for inspection and test activities 1 working day in advance for an inspection for only Contractor for Employer’s Witness/Hold items , Notification 1 week in advance is fabrication area. All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording spection is reviewed and signed by the inspector soon after In case of reviewing documents instead of physical inspections, Subcontractor submits the required documents to confirm acceptance of the applicable activity on time. Contractor has a of those documents. When nonconformity is found during the construction, Contractor instructs Subcontractor to “Nonconformity Control Procedure for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to (implement disposition) only after shall also take corrective actions to prevent recurrence of same or similar registered into Contractor he following data is controlled in each system. Rev.0 Page 8 of 21 specified in 7.4 considering suitable time to submit the inspection notice for inspection and test activities for only Contractor s Witness/Hold items , Notification 1 week in advance is All inspection shall be conducted by Subcontractor and witnessed by Contractor and/or Inspection, measuring, and test equipments shall be properly controlled by Subcontractor in accordance with their procedure including storage, calibration, maintenance, and recording spection is reviewed and signed by the inspector soon after In case of reviewing documents instead of physical inspections, Subcontractor submits the Contractor has a When nonconformity is found during the construction, Contractor instructs Subcontractor to deal “Nonconformity Control Procedure for Construction Work”. Subcontractor is required to submit the Nonconformity Report (NCR) to (implement disposition) only after shall also take corrective actions to prevent recurrence of same or similar registered into Contractor’s own he following data is controlled in each system. 21 of to submit the inspection notice for inspection and test activities s Witness/Hold items deal “Nonconformity Control Procedure (implement disposition) only after s own INDRA 02-OCT-2013

- 9. NSRP Title: Field Quality Control Procedure 7.12 8 8.1 (1) (2) (3) (4) (5) 8.2 8.3 NSRP Complex Field Quality Control Procedure Detailed handling procedure for each system is specified separately. All original QC Subcontractor after registration into related system, and submitted to review as final documentation in accordance with applicable specification. QCRs are as per [ Attachment 7.12 System Handover After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to accordance with applicable specification 8 LIAISON WITH 8.1 Meeting The periodical QC coordination meeting points, to share issues related to quality control. (1) Inspection Schedule (2) Subcontractor Document (3) Welder Qualification (4) Open NCR (5) Other Area of Concern 8.2 Reporting The following reports (1) NCR Status (2) Quality Status (NDE reject ratio, NDE backlog, Test Package) Report 8.3 Notification For Employer 1 working day inspection out of Inspection Notification Form is as [ Attachment Complex Project Field Quality Control Procedure Detailed handling procedure for each system is specified separately. All original QC records with Contractor and/or Subcontractor after registration into related system, and submitted to review as final documentation in accordance with applicable specification. QCRs are as per [ Attachment System Handover After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to accordance with applicable specification LIAISON WITH EMPLOYER The periodical QC coordination meeting share their status, and to exchange views on inspection, quality control, and general issues related to quality control. Inspection Schedule Subcontractor Document Welder Qualification Open NCR Other Area of Concern ollowing reports are NCR Status Quality Status (NDE reject ratio, NDE backlog, Test Package) Report Notification Employer’s witness and hold points, Contractor submits the 1 working day in advance inspection out of construction Inspection Notification Form is as [ Attachment Field Quality Control Procedure Detailed handling procedure for each system is specified separately. records with Contractor and/or Subcontractor after registration into related system, and submitted to review as final documentation in accordance with applicable specification. QCRs are as per [ Attachment-3]. After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to accordance with applicable specification EMPLOYER The periodical QC coordination meeting status, and to exchange views on inspection, quality control, and general issues related to quality control. Inspection Schedule Subcontractor Document e.g. ITP, WPS/PQR and Method Statement Welder Qualification Other Area of Concern are submitted Quality Status (NDE reject ratio, NDE backlog, Test Package) Report ’s witness and hold points, Contractor submits the in advance for an inspection at construction site as mentioned in above Para. Inspection Notification Form is as [ Attachment Detailed handling procedure for each system is specified separately. records with Contractor and/or Employer Subcontractor after registration into related system, and submitted to review as final documentation in accordance with applicable specification. After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to accordance with applicable specification. The periodical QC coordination meeting with Employer status, and to exchange views on inspection, quality control, and general e.g. ITP, WPS/PQR and Method Statement submitted periodically Quality Status (NDE reject ratio, NDE backlog, Test Package) Report ’s witness and hold points, Contractor submits the for an inspection at construction site as mentioned in above Para. Inspection Notification Form is as [ Attachment-4] and its documen Employer Doc. No. Contractor Doc. No. S Detailed handling procedure for each system is specified separately. Employer’s approval shall be compiled by Subcontractor after registration into related system, and submitted to review as final documentation in accordance with applicable specification. After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to Employer is held to discuss and address the status, and to exchange views on inspection, quality control, and general e.g. ITP, WPS/PQR and Method Statement to Emplyer Quality Status (NDE reject ratio, NDE backlog, Test Package) Report ’s witness and hold points, Contractor submits the construction site and site as mentioned in above Para. 4] and its documen Employer Doc. No. Contractor Doc. No. S-000-1670-0001V Detailed handling procedure for each system is specified separately. s approval shall be compiled by Subcontractor after registration into related system, and submitted to Empl review as final documentation in accordance with applicable specification. After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to held to discuss and address the status, and to exchange views on inspection, quality control, and general e.g. ITP, WPS/PQR and Method Statement Quality Status (NDE reject ratio, NDE backlog, Test Package) Report ’s witness and hold points, Contractor submits the NOTIFICATION for INSPECTION site and 1 week site as mentioned in above Para.7.8. 4] and its document flow is shown in [ Attachment Contractor Doc. No. 0001V s approval shall be compiled by Employer through Contractor review as final documentation in accordance with applicable specification. A table of anticipated After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to held to discuss and address the status, and to exchange views on inspection, quality control, and general e.g. ITP, WPS/PQR and Method Statement Quality Status (NDE reject ratio, NDE backlog, Test Package) Report OTIFICATION for INSPECTION 1 week in advance for an t flow is shown in [ Attachment Rev.0 Page 9 of 21 s approval shall be compiled by through Contractor e of anticipated After all construction work is completed, all inspection is completed, and all outstanding such as NCR and system punch items are closed, Contractor issue system handover notice to Employer held to discuss and address the following status, and to exchange views on inspection, quality control, and general OTIFICATION for INSPECTION in advance for an t flow is shown in [ Attachment 21 through Contractor’s e of anticipated After all construction work is completed, all inspection is completed, and all outstanding such as yer in following OTIFICATION for INSPECTION t flow is shown in [ Attachment-5]. INDRA 02-OCT-2013

- 10. NSRP Title: Field Quality Control Procedure HSSE Mgr J. Furumoto FIELD ENG'G Field En NSRP Complex Field Quality Control Procedure HSSE HSSE Mgr J. Furumoto FIELD ENG'G Field Eng'g Mgr Complex Project Field Quality Control Procedure TECHNICAL Field Technical Mgr FIELD QC Field QC Mgr Field Quality Control Procedure ATTACHMENT TECHNICAL Field Technical Mgr FIELD QC Field QC Mgr H. Ishiga ATTACHMENT-1 ORGANIZATION SITE DIRECTOR T.Hayashi CONTROL Field CTRL Mgr K. Inoue QC Engineers Welding Controller System Operator ZONE Contractor's QC Employer Doc. No. Contractor Doc. No. S ORGANIZATION SITE DIRECTOR T.Hayashi CONTROL Field CTRL Mgr K. Inoue HAND OVER Hand Over Mgr QC Engineers Welding Controller System Operator ZONE Contractor's QC Subcontractor's QC NDE Subcontractor Employer Doc. No. Contractor Doc. No. S-000-1670-0001V ORGANIZATION OPERATION Business Mgr T. Hirano HAND OVER Hand Over Mgr QC Engineers Welding Controller System Operator ZONE Contractor's QC Subcontractor's QC NDE Subcontractor Contractor Doc. No. 0001V OPERATION Business Mgr T. Hirano Subcontractor's QC NDE Subcontractor Rev.0 Page 10 of COMMISSIONING Commissioning Mgr of 21 COMMISSIONING Commissioning INDRA 02-OCT-2013