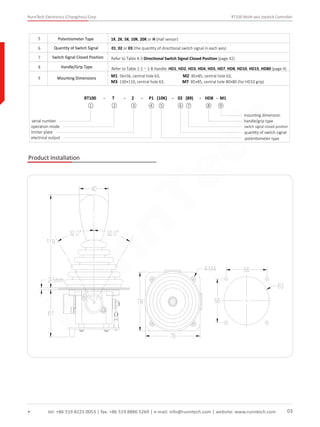

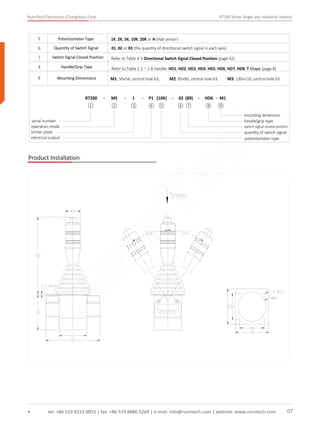

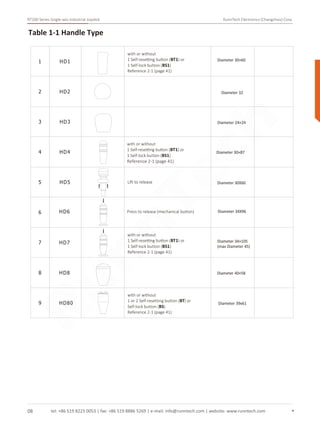

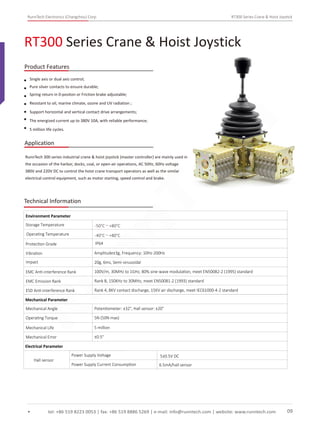

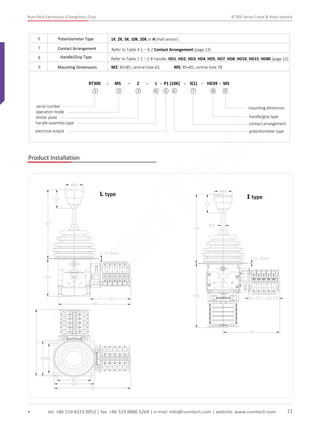

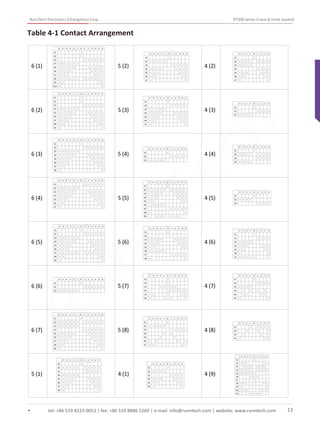

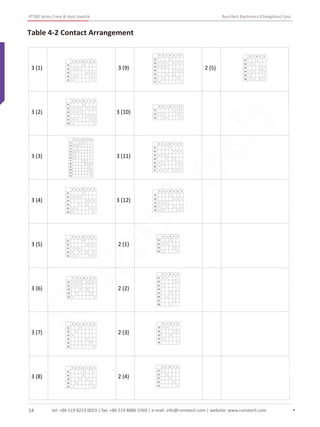

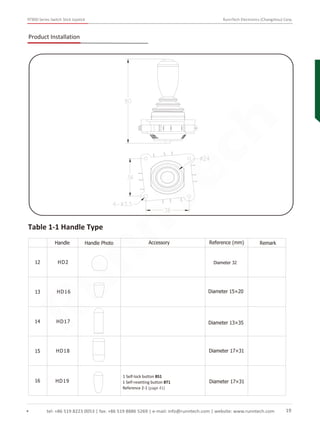

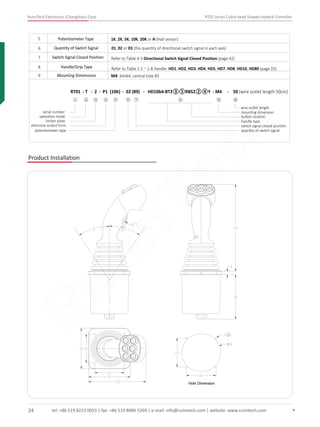

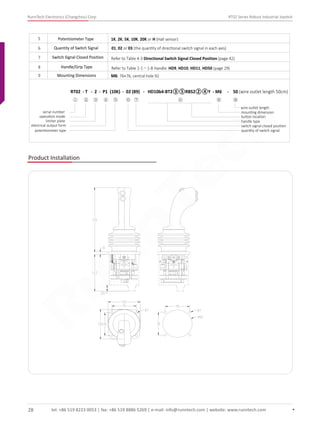

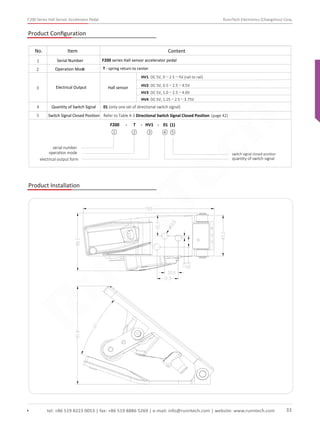

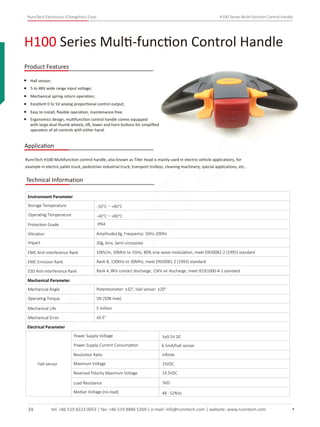

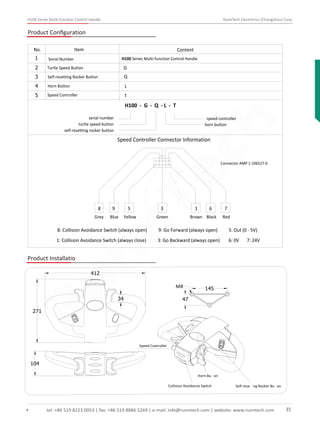

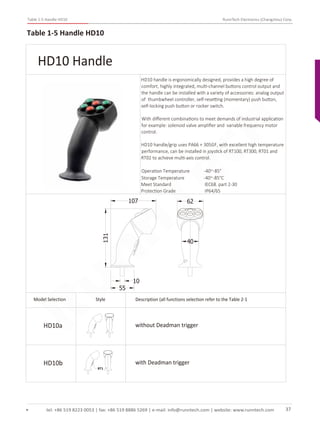

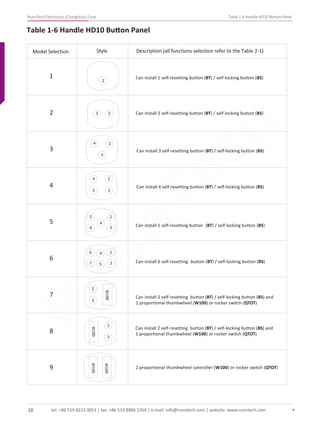

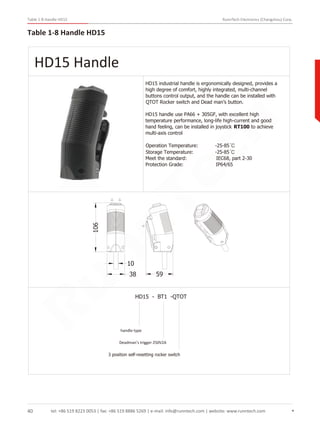

The document details the specifications and applications of the Runntech RT100, RT200, and RT300 series joystick controllers, designed for multi-axis and single-axis control in industrial settings. They feature mechanical and electrical parameters such as analog proportional control outputs, maintenance-free operations, and a lifespan of up to 5 million cycles. Applications include use in hydraulic systems, cranes, marine environments, and various machinery in construction and military settings.