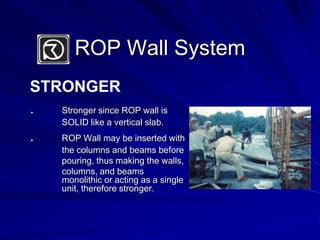

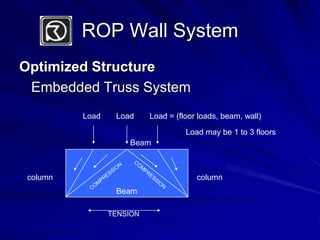

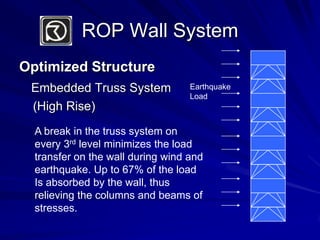

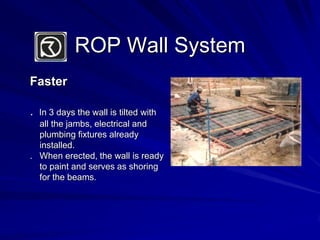

ROP Construction provides a tilt-up concrete wall system called ROP Wall System that is stronger, more optimized structurally, and lighter than traditional concrete hollow block walls. ROP walls are cast-in-place solid concrete walls that are 2-1/4 to 2-3/4 inches thick and can be load bearing up to 2,500 psi. They incorporate an embedded truss system to directly transfer loads to columns, making the building structure stronger yet more economical to construct.