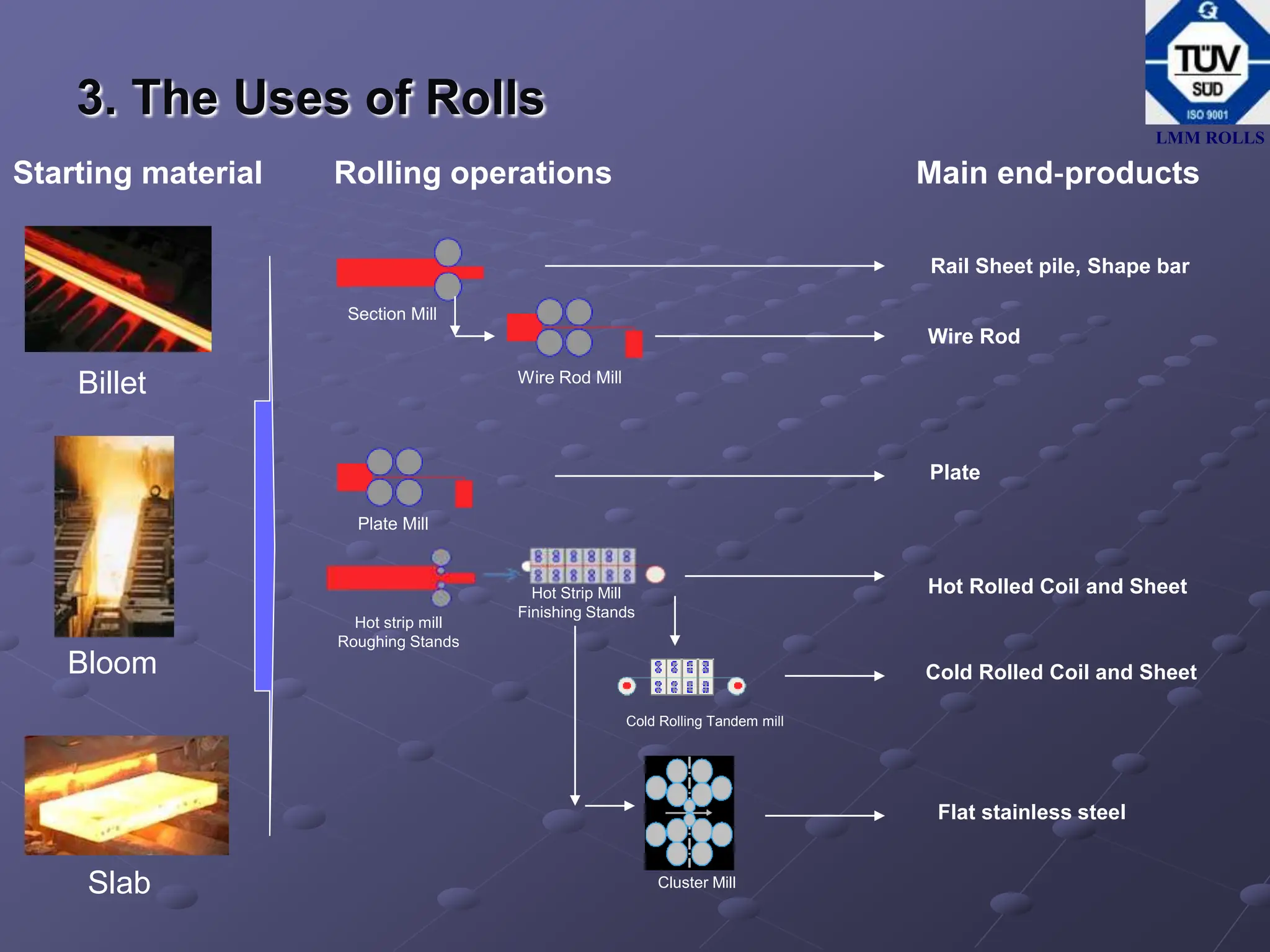

Liaoning Mineral & Metallurgy Group Co., Ltd., established in 1976, manufactures a variety of rolls for different mills, with an annual sales average of €350 million. Their production facility includes advanced machinery and strict quality control measures, producing rolls through casting or forging from materials like steel and iron alloys. The company focuses on product development and technological leadership, catering to industries such as aluminum and steel, with products like high-speed steel, cast iron, and forged rolls.