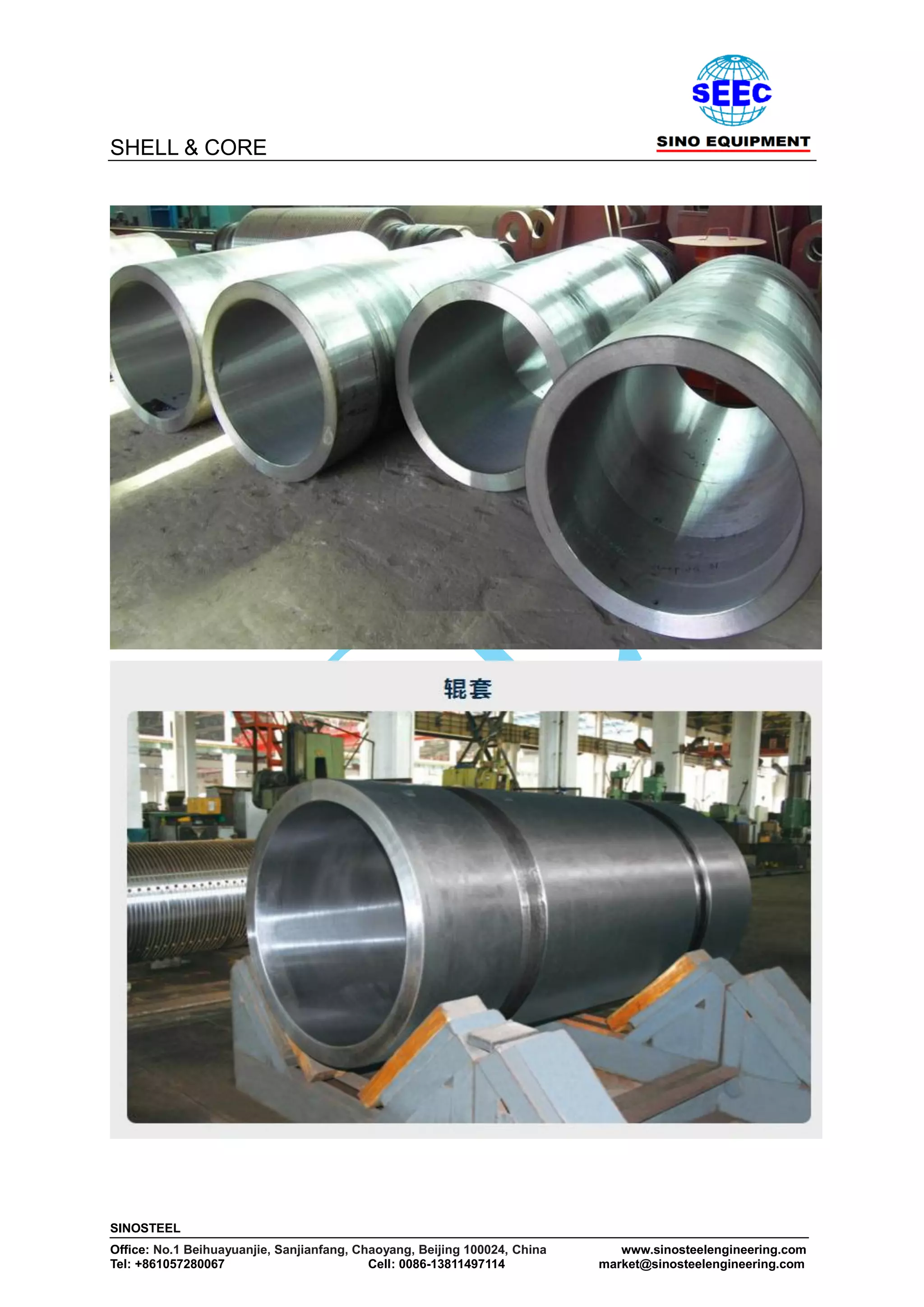

The document is a catalog from Beijing Sino Steel Engineering & Equipment Co., Ltd describing their products and services related to roll shell and core for aluminum casting and rolling machines. It includes details on the materials, manufacturing processes, quality controls, and performance of their Cr-Mo-V alloy steel roller shells and 42CrMo alloy steel roller cores. It aims to demonstrate that Sino Steel's roller shells can operate for over 15,000 tons of aluminum rolling before needing replacement due to improved fatigue resistance from special material treatment and heat processing.