This document provides a curriculum vitae for Rohit Anil Patil. It includes his contact information, educational background receiving a B.Sc. in chemistry in 2012, and work experience including positions at ESSAR STEEL INDIA from 2013 to 2015 and 3 A Composites India PVT LTD from 2015 to present. His objective is to achieve the greatest heights in chemical engineering and the paint industry as a technical officer or production chemist.

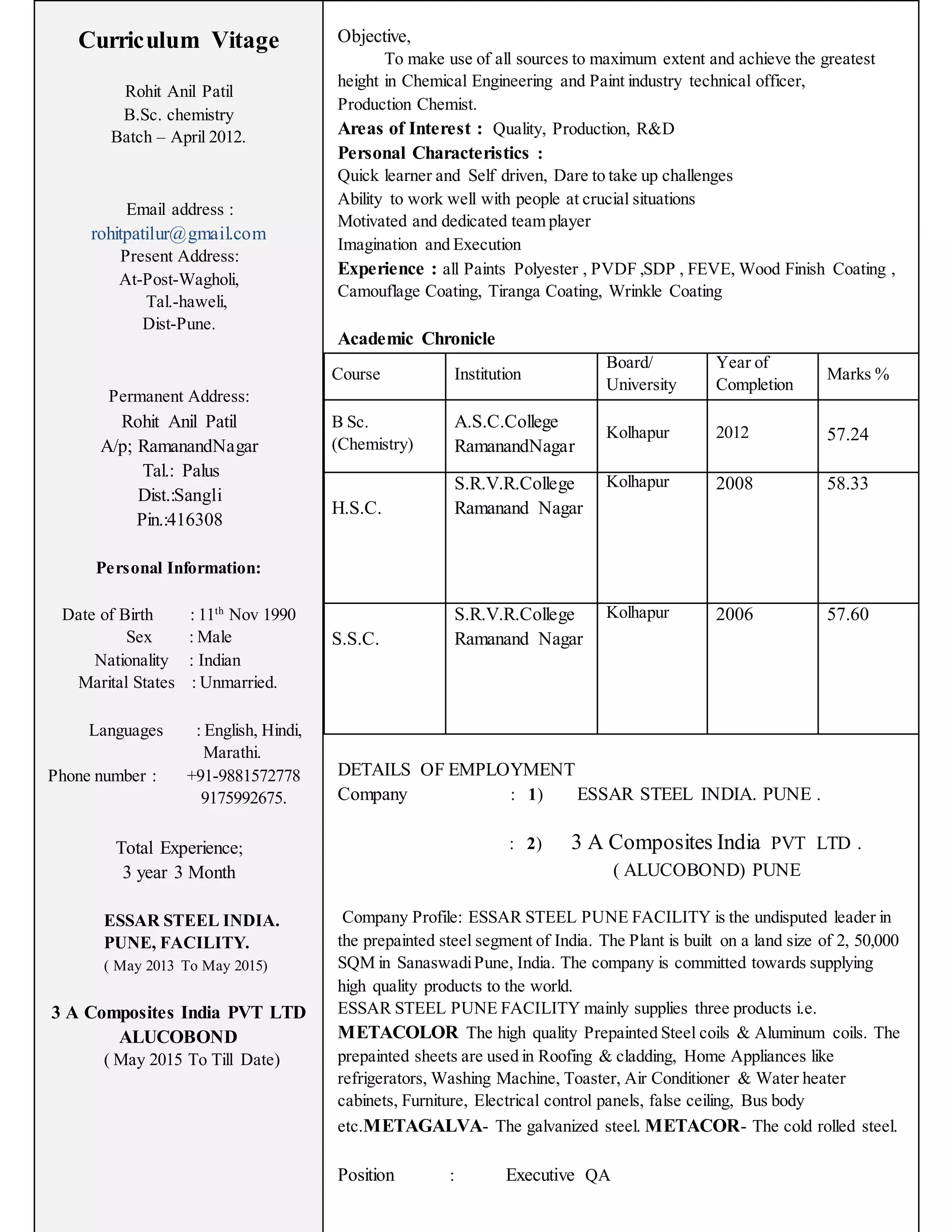

![Roles and Responsibilities

Before paint coating Quality check of shades according to Q. P.

Identify repetitive minor stoppages of Quality online & implement corrective actions.

Close monitoring of color coated sheet at line.

Increase in line output, reduction in defects,and reduction in set up time.

Participation in all activities of set up change of production

Identifying deformation on line color coated coil & taking corrective action.

Continuous improvement in production & quality of finished products.

Maintaining rework & rejection records of panels.

Maintaining 1S, 2S in shop floor

Maintaining Quality related All documentation.

Supervising the Qualities activities as per SOP.

Active co-ordination with other department to run the shop smoothly.

Manpower management in terms of work content.

Work Responsibilities

[ A] Incoming Paint Testing.

1] Shade 2] Gloss 3] Visualization 3] Viscosity 4] Volume % 5] Pencil Hardness 6] Weight Per Liter

7] Paint Coverage 8] Scratch Resistance 9] Cupping 10] Impact 11] Fineness ( Hagman Gauge )

8] T- Bend 9] Acid – Alkali Test. 10] Solvent resistance. 11] Paint application

12] Long Term Test :Salt Sprey, Humidity , Quv ,Natural weathering Test.

[ B] Tinting; Online and lab tinting.

[ C] Shade Development, and shade approval as per party Requirement.

[ D] Process Control: Maintaining the bath parameters of Pre-treatment tank

1] Concentration of Chromium.

2] Concentration of Gardoclean.

3] PH of the solution.

4] Level of the tank.

5] Temperature of Finish and Prime Oven.

6] Setting of line speed according to the various gauge of material.

7] Shade matching & preparation of Shades as per party’s requirements, with the help

Of “BYK GARDNER” spectrophotometer

8] Testing of Zn coating of Galvanize coil,

[ E] Quality testing of finished material after final production.

[ F] Auxiliary line inspection like Slitting & Cut to length End user of SAP system...

[ G] Reports preparation and Submitting to Manager Q.A.

[ H] Action of rejected and Hold material To end use of this material.

Declaration

I hereby declare that the above written particulars are true to the best of my knowledge and belief.

Date yours truly,

Place: Rohit.A.Patil](https://image.slidesharecdn.com/0c8ef69e-2800-4853-9e49-b5aedafce74c-161015203151/85/Rohit-Patil-CV-3A-2-320.jpg)