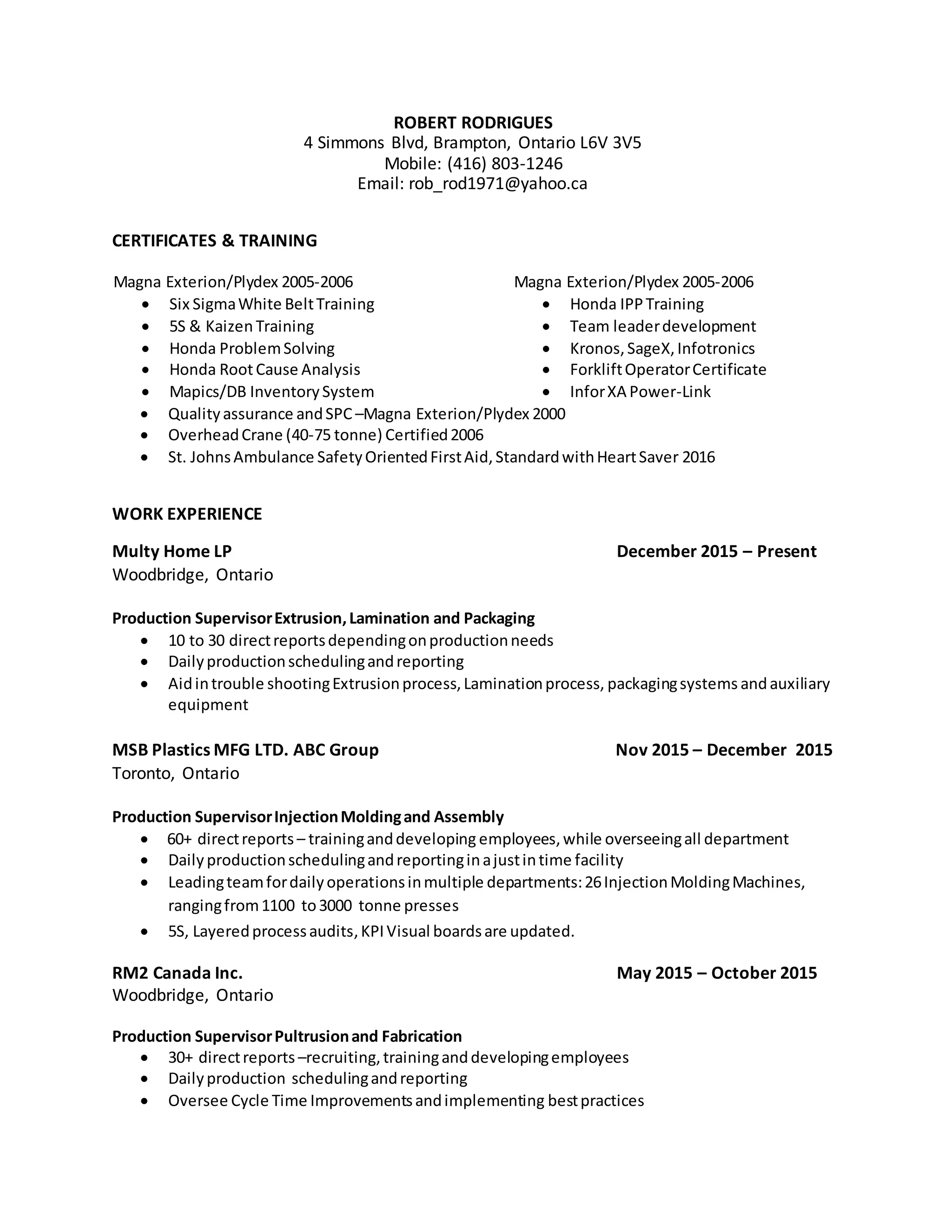

Robert Rodrigues has over 20 years of experience in manufacturing supervision roles. He has a proven track record of reducing costs through continuous improvement initiatives like Lean, Six Sigma, and 5S. His experience spans industries including automotive, plastics, construction, and home building. He has strong leadership, quality assurance, and project management skills.