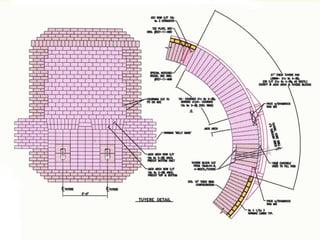

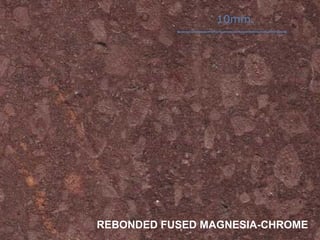

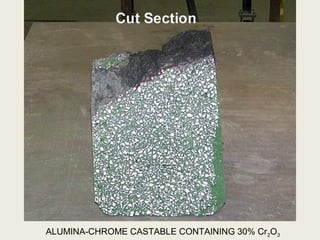

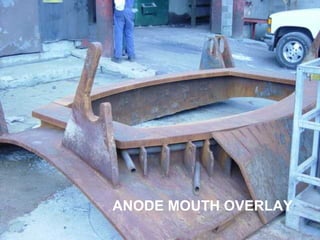

Alumina-chrome refractories can significantly improve wear resistance in high-wear areas of anode refining vessels compared to traditional magnesia-chrome refractories. Specifically, replacing rebonded fused grain magnesia-chrome brick with alumina-chrome refractory at the tuyeres, skimming mouth, and taphole led to up to 250% increased refractory life and allowed for increased annual copper production of 16,000 metric tons due to reduced vessel downtime for repair. Testing also showed no increased leaching of soluble chrome from the alumina-chrome refractory compared to magnesia-chrome.