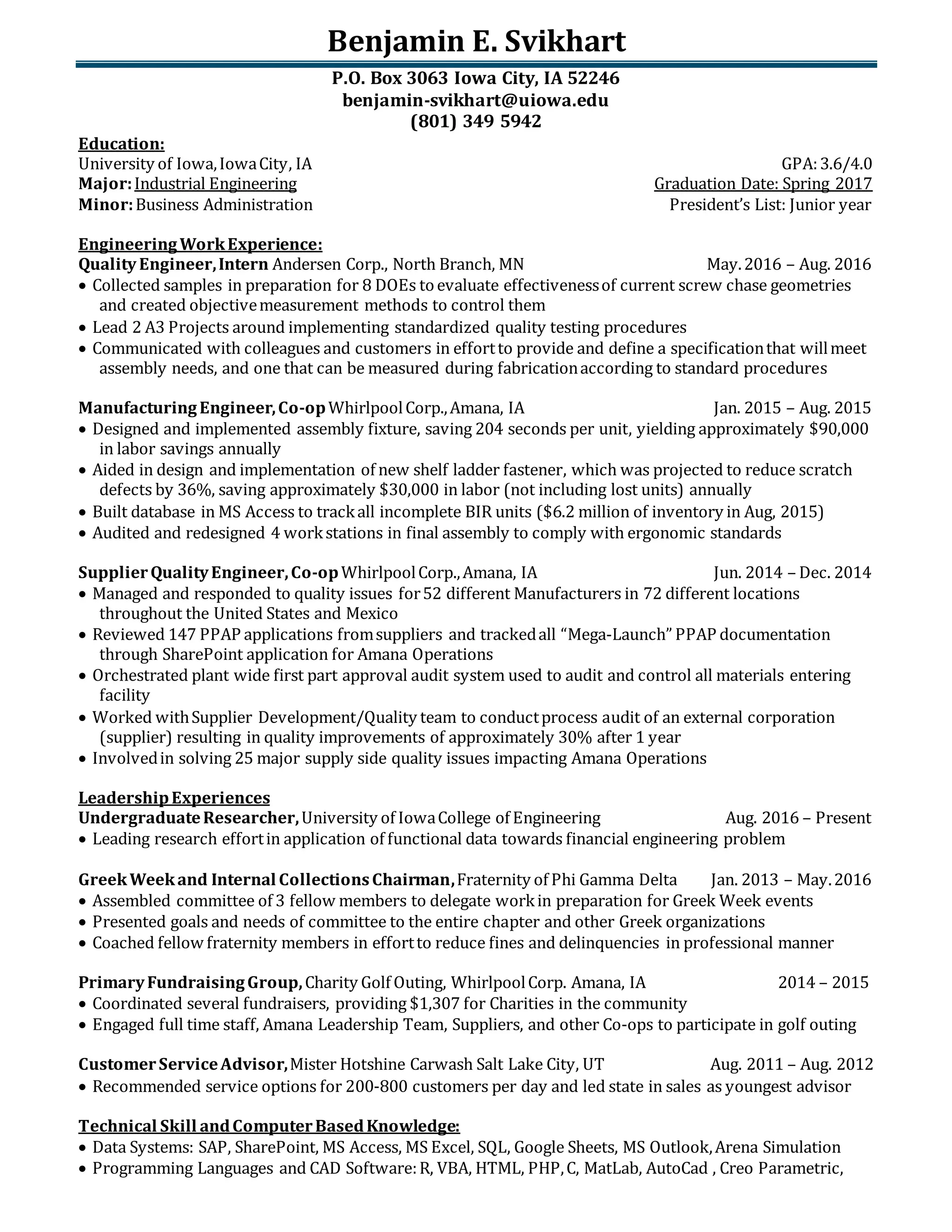

Benjamin E. Svikhart is an industrial engineering student at the University of Iowa seeking a full-time position. He has relevant work experience in quality engineering, manufacturing engineering, and supplier quality engineering. He has a 3.6 GPA and will graduate in Spring 2017 with a bachelor's in industrial engineering and a minor in business administration. He has strong leadership skills and technical abilities including proficiency with SAP, SharePoint, MS Access, Excel, and programming languages.