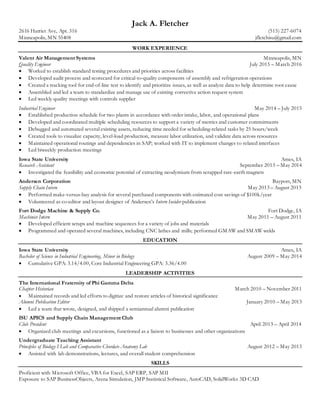

The document is a resume for Jack A. Fletcher that summarizes his work experience and education. It outlines his roles as a Quality Engineer and Industrial Engineer at Valent Air Management Systems, where he established testing procedures, developed audit and tracking tools, and led scheduling efforts. It also lists his experience as a Research Assistant at Iowa State University and internships in supply chain and machining. Fletcher earned a Bachelor's degree in Industrial Engineering from Iowa State University, where he held leadership roles in his fraternity and engineering clubs.