Resume_Dhillon

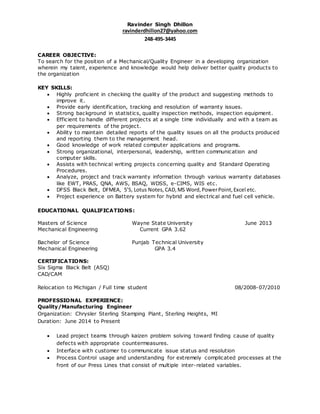

- 1. Ravinder Singh Dhillon ravinderdhillon27@yahoo.com 248-495-3445 CAREER OBJECTIVE: To search for the position of a Mechanical/Quality Engineer in a developing organization wherein my talent, experience and knowledge would help deliver better quality products to the organization KEY SKILLS: Highly proficient in checking the quality of the product and suggesting methods to improve it. Provide early identification, tracking and resolution of warranty issues. Strong background in statistics, quality inspection methods, inspection equipment. Efficient to handle different projects at a single time individually and with a team as per requirements of the project. Ability to maintain detailed reports of the quality issues on all the products produced and reporting them to the management head. Good knowledge of work related computer applications and programs. Strong organizational, interpersonal, leadership, written communication and computer skills. Assists with technical writing projects concerning quality and Standard Operating Procedures. Analyze, project and track warranty information through various warranty databases like EWT, PRAS, QNA, AWS, BSAQ, WDSS, e-CIMS, WIS etc. DFSS Black Belt, DFMEA, 5’S, Lotus Notes, CAD, MS Word,PowerPoint,Excel etc. Project experience on Battery system for hybrid and electrical and fuel cell vehicle. EDUCATIONAL QUALIFICATIONS: Masters of Science Wayne State University June 2013 Mechanical Engineering Current GPA 3.62 Bachelor of Science Punjab Technical University Mechanical Engineering GPA 3.4 CERTIFICATIONS: Six Sigma Black Belt (ASQ) CAD/CAM Relocation to Michigan / Full time student 08/2008-07/2010 PROFESSIONAL EXPERIENCE: Quality/Manufacturing Engineer Organization: Chrysler Sterling Stamping Plant, Sterling Heights, MI Duration: June 2014 to Present Lead project teams through kaizen problem solving toward finding cause of quality defects with appropriate countermeasures. Interface with customer to communicate issue status and resolution Process Control usage and understanding for extremely complicated processes at the front of our Press Lines that consist of multiple inter-related variables.

- 2. Implementation of World Class Manufacturing operating system which encompasses every aspect from Safety, Focused Improvement, Workplace Organization, Logistics, Quality Control, People Development and Environment. Manage deployment of correct means to achieve operational objectives which includes bringing visibility to priority issues, ensuring correct methodology employed to address issues along with cross-functional team members with correct skills and competencies in effort to further develop the organization. Daily interface with all levels of organization from skilled trades to team leaders to mid-level managers to staff and plant manager of stamping and manufacturing. Daily team development of proper skills and competencies to properly attack top issues in manufacturing environment Responsible for departments immediate response for any Quality related concerns at customer location and coordinates any related action and/containment plans. Ensures that breakpoints of containment are achieved and effectively communicated both internally and with the customer. Coordinates and/or supports any product reflash activities at customer locations in the event of a customer plant quality concern. Prepares quality results monthly for all customers including such key metrics as cost of poor quality incurred, design/development related issues affecting quality, delivery results, open issues, etc. Customer Advocate Engineer/Powertrain Quality (Warranty) Organization: Chrysler Tech Center, Auburn Hills Duration: July 2013 – June 2014 Responsibilities: Analyzed Statistical data, warranty data and field issues on to develop problem definitions for root cause analysis. Developed strategy to target real time emerging quality issues through QNA analysis (customer input from dealers) versus the previous strategy utilizing a count on paid claims (C’s/1000). Analyze, project and track warranty information through Technical Assistance, Warranty Claims (EWT, PRAS, QNA, WIS), Dealer calls, Field Early Warranty (FEW) during launch etc. Analyze, project and track Customer survey information through JD Power, Consumer Report, and Customer Quality Index etc. Provides coordination of quality procedures, instructions, specifications and standards to ensure customer satisfaction. Lead and organize resolution meeting to ensure corrective actions implemented and clean stock per commodity. Conduct biweekly meeting with the customer satisfaction team for quality reviews on the new immersing issue and update the database accordingly. Analyze all issues of customers and new products and advocate appropriate resolutions from management. Monitor all customer inquiries and complaints and assist in effective resolution of same. Educates/trains employees on quality and continuous improvement concepts.

- 3. Provides periodic quality summary reports of warranty trend for Management Review. Develop new ways to better satisfy customer needs (new/different equipment, alternative work methods, improved quality/service, etc.) Warranty Parts Validation Specialist/Powertrain Quality Organization: Volkswagen, Auburn Hills Duration: July 2010 - June 2013 Responsibilities: Responsible for reviewing, testing, processing tracking and reporting of automotive parts as they pertains to warranty repairs and returns. Assist suppliers in resolving their quality issues through different Quality methodologies. Partner with dealers when discrepancies are noticed while inspecting and processing of warranty parts and take corrective actions to provide a positive experience for the dealers. Supported Dealers, field staff and corporate employees on claims and parts processing. Developed technical bulletins and tech tips to avoid misdiagnosis, thereby reducing warranty cost. Specialized in Powertrain, Body and Chassis, Electrical, and Hazmat parts (Fuel Pumps, Injectors Airbags and Seat belts, etc . International Tractors Limited of India 05/2008-08/2008 Mechanical Engineer (Internship), Prepared process sheets for each Assembly and Sub-Assembly involved in the whole assembly of tractor so that everything is done in accordance with the standards. Modifications in the Paint shop. Directly involved in the installation and successful implementation of “System for engaging and disengaging the hydraulic lift pump from engine drive for saving the engine power and also increasing the life of hydraulic pump”. Designed a Fixture for pre-installation of locking pins in the Gear shifter forks to avoid bending of gear shifter rods. Full Time student 12/2004-05/2008 Indian Railways Coach Building Factory 06/2004-12/2004 Mechanical Engineer (internship) Study of End Wall of conventional as well as LHB coaches Study of paint process of coaches MEMBERSHIP: American Society for Quality