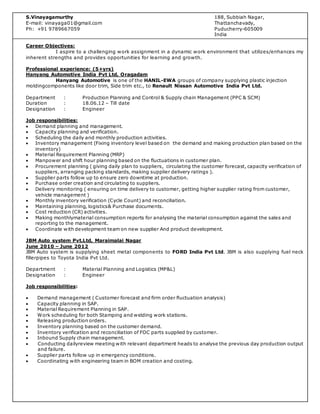

S. Vinayagamurthy is a mechanical engineer with over 5 years of experience in production planning, supply chain management, and material logistics in the automotive industry. He has worked for Hanyang Automotive and JBM Auto Systems, focusing on demand planning, inventory management, and procurement planning. He holds a bachelor’s degree in mechanical engineering and is proficient in SAP PP, Microsoft Excel, and AutoCAD.