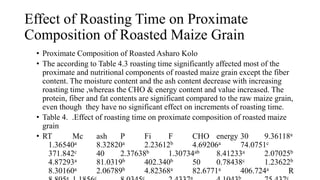

- The document describes the design and testing of a maize grain roaster. It analyzes the roaster's components, including the cylinder and frame.

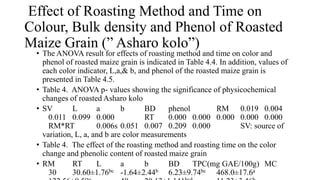

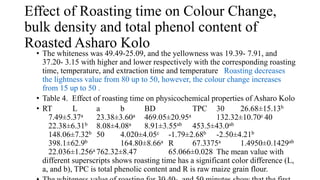

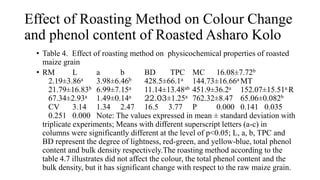

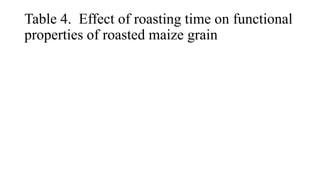

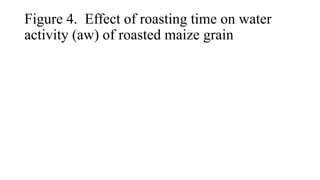

- Experiments were conducted to evaluate how roasting method and time affect properties of the roasted maize like moisture content, color, phenol content, and functional qualities. Longer roasting times and the manufactured roaster led to greater changes.

- Analysis found the manufactured roaster improved energy conservation compared to traditional open pan roasting, as it achieved higher internal temperatures and less heat loss to the environment.

![Solid Work Design and Manufacturing of

Maize Grain Roaster

• The maize grain roaster was designed using solid work version

[30.1.0.0082/11.16.5.0] and manufactured from locally available materials.

The resultant manufactured roaster has composed of different components as it

is mentioned above at section ( 3.2.2 to 3.2.4).The main categories are the

cylinder, the shell that covers the cylinder, the frame, and the burning chamber.

The size of the roasting cylinder is 56 cm in diameter and 86 cm in length. The

cylinder also consists of internal and external parts. The internal part has

horizontal baffles, hollow shaft rod metal, and normal supports. The external

part of the cylinder consists of the hollow shaft that passes through the

cylinder, the inlet and outlet ports, the hopper, and the bearing support that

connects the frame and the main cylinder, which holds the grain. The design

and fabrication of each part of the grain roaster is described below.](https://image.slidesharecdn.com/resultanddiscussionppt-240213070130-e3389b15/85/RESULT-AND-DISCUSSION-ppt-pptx-2-320.jpg)