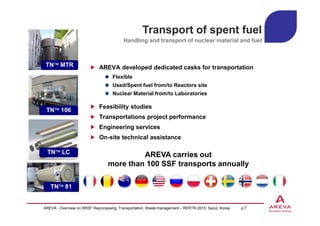

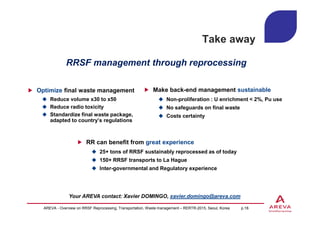

1. AREVA transports research reactor spent fuel (RRSF) to its La Hague reprocessing plant in dedicated casks.

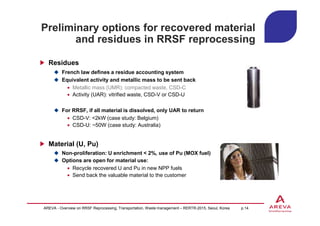

2. At La Hague, the RRSF is reprocessed through dissolution and separation processes to recover valuable materials and produce standardized final waste packages.

3. AREVA has reprocessed over 150 shipments of RRSF from over 20 reactors in 11 countries, totaling over 7 tons, gaining extensive experience in RRSF management.