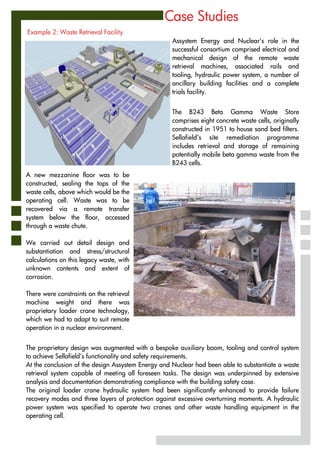

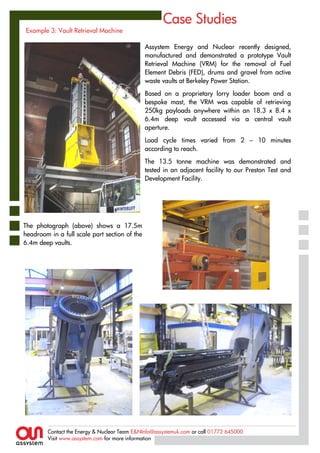

Remote Waste Retrieval provides design and equipment for remotely handling nuclear waste, including size reduction, compaction, and encapsulation. They have extensive experience designing specialized equipment like remote retrieval machines to safely containerize and categorize waste. Their solutions include remotely operated vehicles, shielded transfer enclosures, and transportation equipment. They have designed innovative machines for removing intermediate-level waste and mechanical systems to retrieve waste from legacy storage sites.