Embed presentation

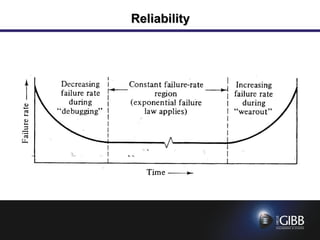

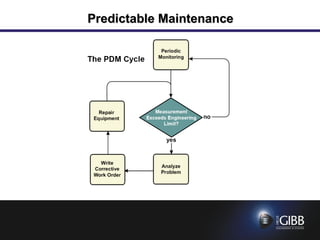

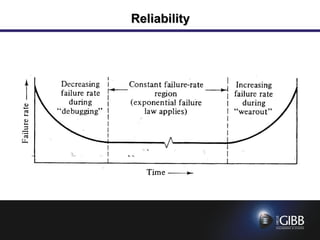

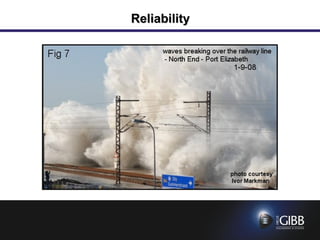

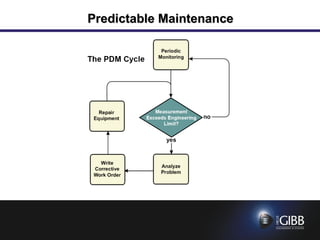

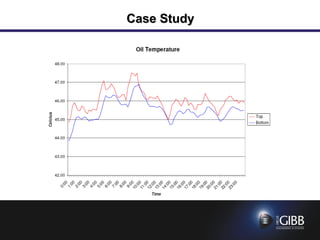

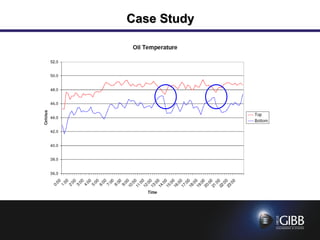

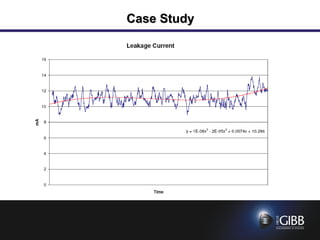

The document discusses reliability centered maintenance using a predictable strategy. It defines reliability and discusses various maintenance strategies such as corrective, preventive, condition-based and predictive maintenance. Predictive maintenance is highlighted as it compares measured parameters against engineering limits to detect and correct problems before failures occur. A case study is mentioned but not described. The summary notes advantages of the predictable strategy including being cost effective, requiring reduced experience levels, and reduced risk, while acknowledging the potential disadvantage of implementation.