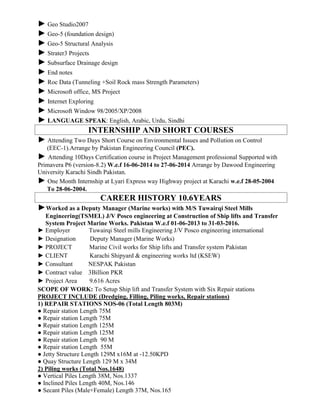

This curriculum vitae summarizes Mujeeb Ur Rehman's qualifications and experience. He has over 10 years of experience managing complex civil engineering projects. He holds a Master's degree in Civil Engineering with a specialization in Geotechnical Engineering from NED University and a Bachelor's degree in Civil Engineering from Mehran University. His experience includes roles as a Deputy Manager and Project Engineer on large projects such as construction of ship lifts and marine works for a nuclear power plant.