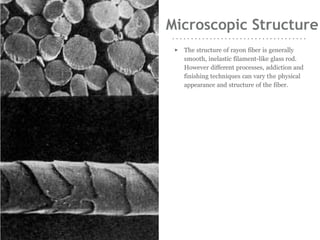

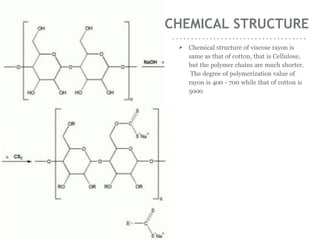

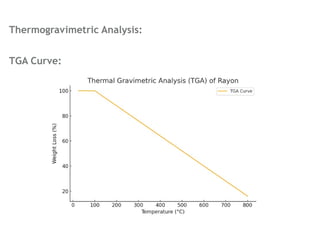

Rayon is a versatile and economical fiber made from cellulose, known for its comfort and ability to mimic other textiles. Its structure includes a smooth, inelastic filament, and its thermal analysis indicates stability at low temperatures, with significant weight loss due to thermal degradation above 200°C. The fiber boasts various applications in apparel, home furnishings, and industrial uses, but it has limited elastic recovery and is best maintained through dry cleaning.