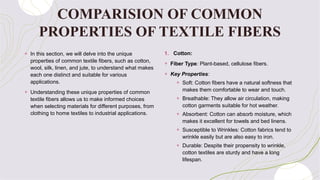

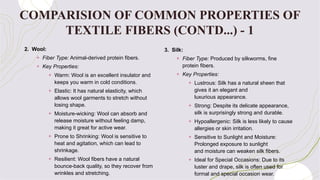

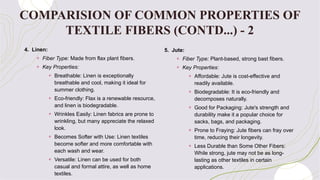

The document provides a comprehensive overview of textile fibers, focusing on their identification, characteristics, and applications in various industries such as fashion and manufacturing. It discusses both traditional fibers like cotton, wool, and silk, as well as unconventional fibers like bacterial cellulose and spider silk, outlining their unique properties and potential uses. Additionally, it emphasizes the importance of fiber identification for quality control, product development, and consumer care.