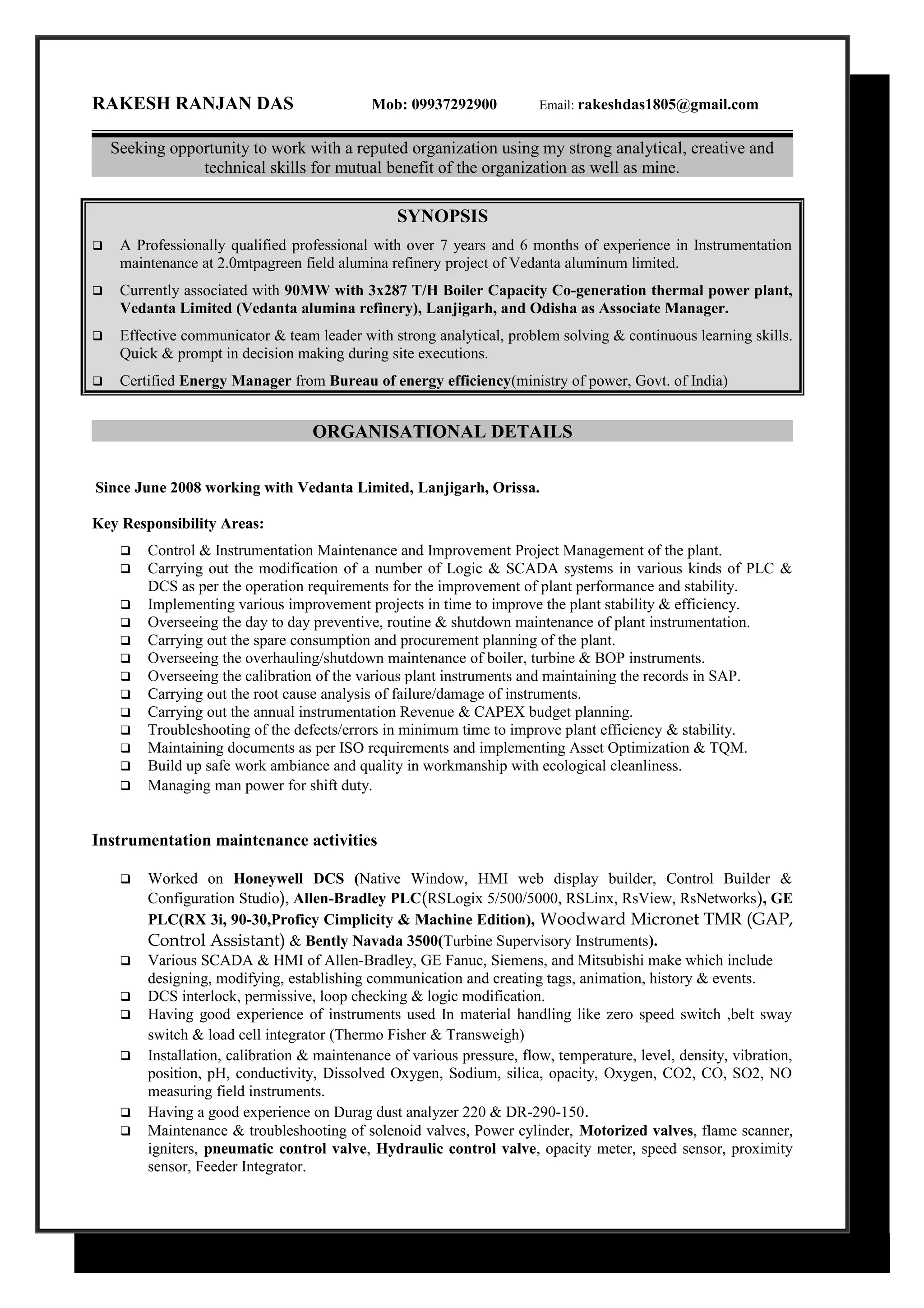

Rakesh Ranjan Das is seeking new opportunities and has over 7 years of experience in instrumentation maintenance. He currently works as an Associate Manager overseeing instrumentation maintenance at a 90MW cogeneration power plant. He has strong technical and problem solving skills and experience working with DCS, PLC, and SCADA systems. Key responsibilities include maintenance planning and projects to improve plant efficiency.