RAJA PRAKASH BALASUBRAMANIAN

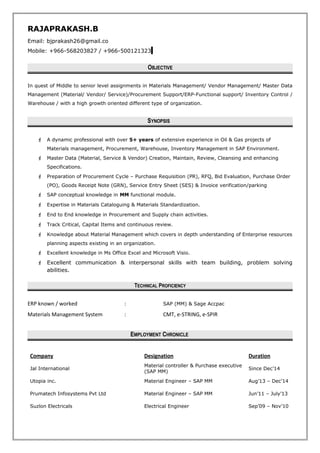

- 1. RAJAPRAKASH.B Email: bjprakash26@gmail.co Mobile: +966-568203827 / +966-500121323 OBJECTIVE In quest of Middle to senior level assignments in Materials Management/ Vendor Management/ Master Data Management (Material/ Vendor/ Service)/Procurement Support/ERP-Functional support/ Inventory Control / Warehouse / with a high growth oriented different type of organization. SYNOPSIS A dynamic professional with over 5+ years of extensive experience in Oil & Gas projects of Materials management, Procurement, Warehouse, Inventory Management in SAP Environment. Master Data (Material, Service & Vendor) Creation, Maintain, Review, Cleansing and enhancing Specifications. Preparation of Procurement Cycle – Purchase Requisition (PR), RFQ, Bid Evaluation, Purchase Order (PO), Goods Receipt Note (GRN), Service Entry Sheet (SES) & Invoice verification/parking SAP conceptual knowledge in MM functional module. Expertise in Materials Cataloguing & Materials Standardization. End to End knowledge in Procurement and Supply chain activities. Track Critical, Capital Items and continuous review. Knowledge about Material Management which covers in depth understanding of Enterprise resources planning aspects existing in an organization. Excellent knowledge in Ms Office Excel and Microsoft Visio. Excellent communication & interpersonal skills with team building, problem solving abilities. TECHNICAL PROFICIENCY ERP known / worked : SAP (MM) & Sage Accpac Materials Management System : CMT, e-STRING, e-SPIR EMPLOYMENT CHRONICLE Company Designation Duration Jal International Material controller & Purchase executive (SAP MM) Since Dec’14 Utopia inc. Material Engineer – SAP MM Aug’13 – Dec’14 Prumatech Infosystems Pvt Ltd Material Engineer – SAP MM Jun’11 – July’13 Suzlon Electricals Electrical Engineer Sep’09 – Nov’10

- 2. AREAS OF EXPOSURE & EXPERTISE Master Data Management (Material, Service & Vendor): Preparing all Master data (Material master, Vendor master, Service master etc.,) to suit any ERP. Strong knowledge in MESC, UNSPSC, SHELL CMT coding. Master data preparation, Classification, Cleansing & Enrichment. Create Class Master, Attribute Master, and UOM Master Etc. Coding & Cataloguing (Coding schedule, Noun& Modifier, Templates, Specifications) ERP Material Master Codification & Material Cataloguing. Creation of Material Codes for Piping Material, Raw Material, Structural, Electrical, Instrumentation, Spare parts, Tools & Tackles, Consumables & all types of Standardized Engineering items in ERP database. Data Cleansing: detect, remove and/or correct data that is incorrect, out-of-date, redundant or incomplete. This ensures that there is data integrity, leading to optimum performance of the system. Data Enrichment: added value to data to make it highly structured & formation the source data with reference from the manufacturer’s catalogue or through other resources. Structured Cataloguing, whereby classification of material data is carried out based on the noun and modifier system of cataloguing and data is structured according to standard attributes. Cross referencing of materials i.e. identifying equivalent item from a different manufacturer, identification of a similar item with almost the same specifications from a different manufacturer. SAP Functional – MM (Materials Management) Module “Super user” Role: Expertise in Materials Management in SAP ECC (6.0): Creation of Material Master, Vendor Master, Service Master, Purchase Requisition (PR), Purchase Order (PO), Stock Transfer Order (STO), Physical Inventory, Vendor evaluations and Goods Receipt Note (GRN), Service Entry Sheet (SES), Goods Issue Note (GIN), Inventory Management, Invoice Verification (IV), Movement Types etc. Procurement/Purchasing Management: Handling Purchase related all responsibilities – PR to PO all processes, New vendor development, Price negotiation with vendor, Material Delivery & Payment. Purchasing all kind of Materials (Electrical, Mechanical, ITM & Civil). Follow up to vendors/suppliers/contractors the requirement/s of the end user request for quotation. Participation in Negotiations with vendors Post Order Follow-up (Expediting) with Suppliers/Service providers for timely delivery of materials. Ensure Suppliers/Service providers adhere strictly to brand or make and test specifications and that materials and equipment received, meet specified quality standards and all stated performance criteria Interaction with finance department. For any short comings regarding Payment and ensuring the payment is done on time to vendors/suppliers/Service providers. Store/Warehouse/Inventory Management:

- 3. Direct & manage all the Warehouse & Inventory activities through SAP MM. Clearing & Forwarding all GRNs to Accounts Dept. for remittance as per order terms Strong SAP Skills: Handles large scale material transactions. Manages the storage capacity and ensures utilization of space. Monitoring & analysis of incoming material receipt & consumption reports to remove the bottlenecks in smooth functioning of material receipts & issues in ERP system. Inspection of Domestic & Imported Project Material with respect to their Invoice, Challan & Packing List (PL) against PO. Coordinates with other departments (i.e. Production, Purchase & QC departments) for the effective & efficient function of Warehouse & Inventory. Experience of managing Inventories like Piping and Valve Material, All types of Engineering Goods, Structural Steel, Scaffolding & Shuttering, Cables, Cable Tray/Accessories, Tools/Tackles, Welding Electrodes & filler Wires etc. Proper receipt, storage, preservation and issue of materials, accounting, efficient handling, declaring surplus/unserviceable materials, keeping stores records. Periodical physical stock verification. Control of critical items and slow/non-moving items. Sending material to outside parties for coating ,Job-work & Preparing Dispatch advice . PROFESSIONAL EXPERIENCE Jal International, Dammam, Saudi Arabia Materieal Controller & Purchase Executive – (Materials Management / SAP – MM) (Dec – 2014 To till date) Working as Super user of SAP MM Module for all ongoing upstream projects with Hands on experience of all transactions related to Material Master, Vendor Master, Service Master, Purchase Requisition, Purchase Order, and all related material purchasing activities. Major Responsibilities:- In charge of Material Master, Service Master & Vendor Master for all on going Procurement of Materials/Services. Continuously monitor, review and moderate SAP Master Data procedures and standards to ensure that quality data is available for business use and planning. Contacting Vendors for getting Manufacturer Part number or Model number. Handling Purchase related all responsibility – PR to PO all process, New Vendor Development, Price negotiation with vendor, Material Delivery and Payment. Sending RFQ to the multiple vendors & getting quotations Price Bidding to the vendors Creation of Purchase Order(PO) (Capital) Stock Transfer Order (STO) from One Plant to another Plant within a Company. Follow up for the vendors, SASO certification, Payment terms, LC coordination Material Management Planning for daily consumables material for next one month

- 4. Checking the Petty cash Purchases from local purchaser. Checking proposals & quotation comparisons form our buyer before submitting to management. Materials cataloguing as per the company norms and upload in SAP. Values populated from the input and Mnfr websites for these attributes for Material master data. Maintaining Material master attributes for material types like HIBE, KANBAN, CSDT, UNBW Preparing Master data for Manufacturing Information & Technical specification. Quality Controls of all requests as per KPI. Supporting Purchasing & Material Management activities for my company. Monitor shipments to ensure that goods come in on time and resolve problems related undelivered goods. Processing for the Material Master, Vendor Master & Asset Master data for the Projects Preparing SAP Material Management end user manual which help to the end user. Utopia inc., Bangalore Materials Engineer – SAP MM (August – 2013 to December – 2014) Worked as Material Engineer for all ongoing upstream projects with Hands on experience of all transactions related to Material Master, Vendor Master. Major Responsibilities:- Projects: 1.Cargill, 2.Butterball, 3.Ats, 4.Aryzta Creation, modification & extension of Master data which includes Material Master, Service Master & Vendor Master in the SAP system with all required views & data’s. Processing for the Material Master & Vendor Masters data for the Projects Materials Coding & cataloguing as per the Business rules. Values populated from the input and websites for these attributes. Duplicate part identification and removal. Preparing Master data for Manufacturing Information & Technical specification. Quality Controls of all requests as per SLA & KPI. Evaluation of data quality and correctness. Verifying various documents related to Material receipts / issue / transfer. 100% matching of physical stock & system stock at any given time. Project: Cenovus, Canada (Online client- Bill of Materials) Processing for the Material Master & Vendor Masters data for the Projects Preparing SAP uploading format for Equipment Master, Bill of Materials and inventory items. BOM linking with corresponding equipments Ensuring supplier's data tightly aligned, reducing purchasing error. Quality management checks are carried out during the production process and before delivery. Identification of Maintainable Spares and Bill of Materials (Spare Parts). Study As built drawings and creating spares based on that drawings and documents. Study P&ID diagrams and extracting tags and equipments.

- 5. Prumatech Infosystems Pvt Ltd, Chennai Materials Engineer (June – 2011 to July – 2013) Client : SHELL & Saudi Aramco shell Refinery Company (SASREF) SAP, MESC based material creation The Online Material Master Maintenance of SAP is done for Shell Global Solutions International. At present these service is provided for various operating units of SHELL through a dedicated Leased line facility. Worked as a Material Engineer for SHELL - EPSAP project in this Doing MM cataloging for 16 various plants of shell like (SMEP(MALAYSIA), EPW(US), BSP(SPAIN), SEIC(CHINA), PDO (OMAN), ARROW ENERGY, SPDC, EPE, ETC…) in SAP. Major Responsibilities:- Developing Logic for Codification (i.e. Main Group, Sub-Group, Sub-Sub-Group & Item number with Indicator). Involved in the Quality Checking and removing the duplicate data from the Material/Vendor Master. Materials Coding, cataloguing and maintaining in SAP as per the Big rules (Shell standard-MESC). Values populated from the input and websites for these attributes using Masterpiece (CMT). Duplicate part identification and removal. Online maintenance of material master catalogue for Shell Maintaining Material master attributes for material types like HIBE, CSDT, UNBW Preparing Master data for Manufacturing Information & Technical specification. Quality Controls of all MSVC requests as per KPI. Creation of MESC & UNSPSC Codification Structure to provide Service Hierarchy Prepared Project Scheduling and Execution plan and management information reports. Conducted Presentation through power point about Project Work. Assigned Equipment Criticality (ABC Indicator) after studying Nature of Process. Performed Warehouse maintenance in line to ERP. Prepared Spare parts interchangeability Records (SPIR) for Complete Tag List. Suzlon Electricals, Coimbatore Electrical Engineer (September – 2009 to November – 2010) Major Responsibilities:- Guiding team for issuance of Protection Single Line Diagrams, General Arrangement drawings and Bills of Material Erection for Control and Relay panels for 400/220/132/66/33/11 kV voltage levels as per customer specification/ SLD for Line, Transformer, Reactor, Busbar, Bus Coupler, Transfer Bus Coupler for different busbar (1.5B, DM, DMT etc) arrangements Validation of Interpanel Wiring Chart and TB list & Label list Preparing purchase request for equipment ordering & panel fabrication Testing of 20 MVA & 12.5 MVA Power Transformer

- 6. Doing quality checks in control panel arrangements and bus bar alignments and corresponding airgaps between busbars. Testing of CT, P. T., CVT, Circuit breaker, switch gear and Power Transformer Trouble shooting of all Electrical circuits, control and protection circuits. EDUCATIONAL CREDENTIALS Engineer in Electrical & Electronics Engineering (EEE) with 66% in June 2009 from JJ college of Engineering, Tamil Nadu. (1st class throughout academic career) Diploma in Electrical & Electronics Engineering (DEEE) with 74% in June 2006 from Shanmugha Polytechnic College, Tamil Nadu. (1st class throughout academic career) PERSONAL DOSSIER Date of Birth : 30th June 1986 Known Languages : Tamil, English & Hindi Passport No : H5507729 Marital Status : Single Nationality : Indian Communication Address : 1/166, East street, Sembiyakudi, Ariyalur - 621722 DECLARATION I hereby declare that the above stated Information is true and correct. If given an opportunity in your esteemed organization, I will discharge my duties to your utmost satisfaction Rajaprakash.B

- 7. Doing quality checks in control panel arrangements and bus bar alignments and corresponding airgaps between busbars. Testing of CT, P. T., CVT, Circuit breaker, switch gear and Power Transformer Trouble shooting of all Electrical circuits, control and protection circuits. EDUCATIONAL CREDENTIALS Engineer in Electrical & Electronics Engineering (EEE) with 66% in June 2009 from JJ college of Engineering, Tamil Nadu. (1st class throughout academic career) Diploma in Electrical & Electronics Engineering (DEEE) with 74% in June 2006 from Shanmugha Polytechnic College, Tamil Nadu. (1st class throughout academic career) PERSONAL DOSSIER Date of Birth : 30th June 1986 Known Languages : Tamil, English & Hindi Passport No : H5507729 Marital Status : Single Nationality : Indian Communication Address : 1/166, East street, Sembiyakudi, Ariyalur - 621722 DECLARATION I hereby declare that the above stated Information is true and correct. If given an opportunity in your esteemed organization, I will discharge my duties to your utmost satisfaction Rajaprakash.B