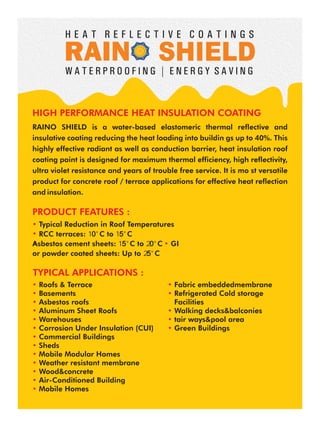

The document describes Raino Shield, a water-based elastomeric coating that provides thermal reflective and insulative properties. It reduces heat loading in buildings by up to 40% and lowers roof temperatures by 10-25°C depending on the material. The coating has high reflectivity, UV resistance, and durability. It is suited for concrete roofs, terraces, and other structures. Application instructions and specifications are provided.