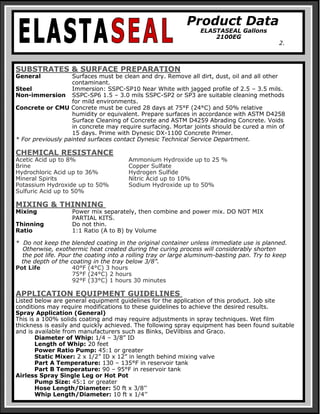

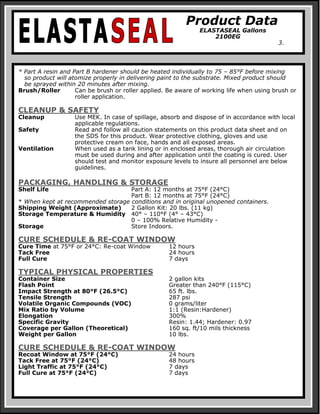

This document summarizes the properties and application of ELASTASEAL, a flexible epoxy coating designed for applications requiring high elongation. ELASTASEAL can tolerate expansion and contraction, adjusts to freeze-thaw cycles, and provides corrosion protection for surfaces like cooling towers, expansion joints, and concrete. It is a 100% solids, solvent-free coating that offers excellent adhesion and flexibility with elongation up to 300%. ELASTASEAL can be applied to surfaces like metal, concrete, wood, and geotextiles, and is suitable for uses like tank linings, secondary containment, and crack repair.