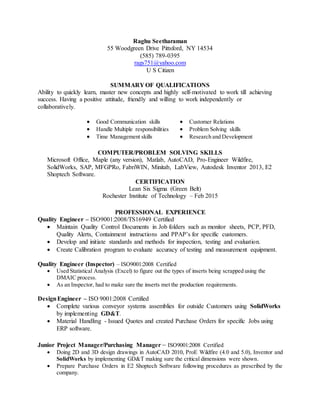

Raghu Seetharaman has over 15 years of experience in engineering roles including quality engineer, design engineer, project manager, and purchasing manager. He has a master's degree in mechanical engineering and certifications in Lean Six Sigma and CAD software like AutoCAD, SolidWorks, and ProE. His resume emphasizes skills in quality control, statistical analysis, mechanical design, project management, and purchasing.