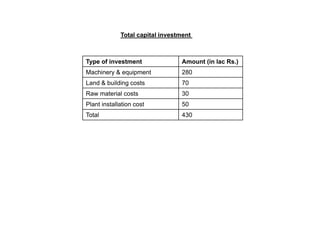

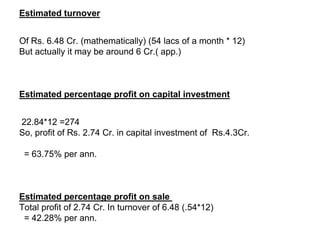

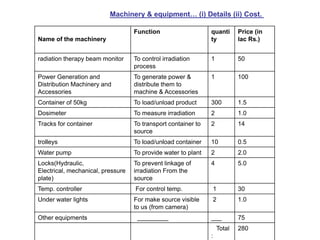

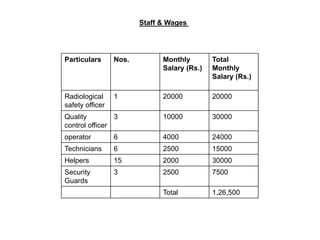

This document summarizes the key points of a proposal for a food irradiation facility. It discusses how irradiation can eliminate disease-causing germs from foods while maintaining nutritional value. The summary includes the proposed machinery and costs, staffing plan and wages, other expenses, break-even analysis, financial viability, estimated turnover and profits. The proposal requests a total investment of 4.3 crore rupees, and estimates annual profits of 63.75% on investment and 42.28% on sales.

![Break even analysis

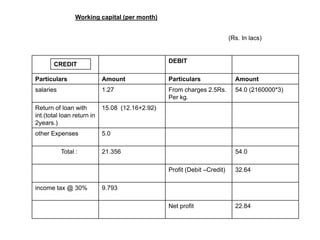

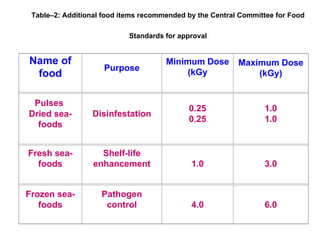

Particulars Amount (Rs.

No in lacs)

[A] Turnover 54.0

[B] Variable Costs

Salaries 1.27

other Expenses 5.0

Total : 6.27

[C] Contribution [A] - [B] 47.73

[D] Fixed Cost 430

[E] Break-Even Point [D] ÷ [C] 9.009%](https://image.slidesharecdn.com/radiationpreservation-12703566826557-phpapp02/85/Radiation-Preservation-15-320.jpg)